Magnesium is a chemical element with the symbol Mg and atomic number 12. It is a shiny gray metal having a low density, low melting point and high chemical reactivity. Like the other alkaline earth metals it occurs naturally only in combination with other elements and it almost always has an oxidation state of +2. It reacts readily with air to form a thin passivation coating of magnesium oxide that inhibits further corrosion of the metal. The free metal burns with a brilliant-white light. The metal is obtained mainly by electrolysis of magnesium salts obtained from brine. It is less dense than aluminium and is used primarily as a component in strong and lightweight alloys that contain aluminium.

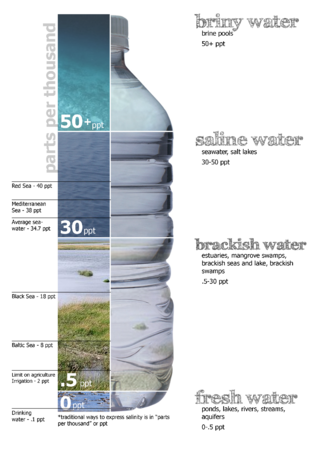

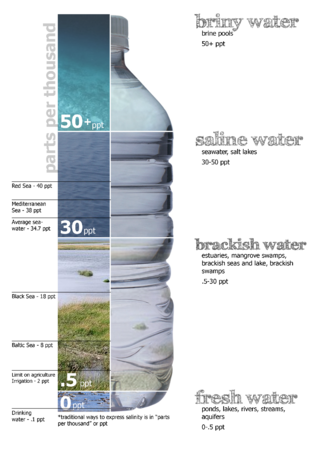

Brine is a high-concentration solution of salt in water. In diverse contexts, brine may refer to the salt solutions ranging from about 3.5% up to about 26%. Brine forms naturally due to evaporation of ground saline water but it is also generated in the mining of sodium chloride. Brine is used for food processing and cooking, for de-icing of roads and other structures, and in a number of technological processes. It is also a by-product of many industrial processes, such as desalination, so it requires wastewater treatment for proper disposal or further utilization.

Distilled water is water that has been boiled into vapor and condensed back into liquid in a separate container. Impurities in the original water that do not boil below or near the boiling point of water remain in the original container. Thus, distilled water is a type of purified water.

The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef Bayer. Bauxite, the most important ore of aluminium, contains only 30–60% aluminium oxide (Al2O3), the rest being a mixture of silica, various iron oxides, and titanium dioxide. The aluminium oxide must be further purified before it can be refined into aluminium metal.

Calcium chloride is an inorganic compound, a salt with the chemical formula CaCl2. It is a white crystalline solid at room temperature, and it is highly soluble in water. It can be created by neutralising hydrochloric acid with calcium hydroxide.

Hard water is water that has high mineral content. Hard water is formed when water percolates through deposits of limestone, chalk or gypsum, which are largely made up of calcium and magnesium carbonates, bicarbonates and sulfates.

Water cooling is a method of heat removal from components and industrial equipment. Evaporative cooling using water is often more efficient than air cooling. Water is inexpensive and non-toxic; however, it can contain impurities and cause corrosion.

Purified water is water that has been mechanically filtered or processed to remove impurities and make it suitable for use. Distilled water was, formerly, the most common form of purified water, but, in recent years, water is more frequently purified by other processes including capacitive deionization, reverse osmosis, carbon filtering, microfiltration, ultrafiltration, ultraviolet oxidation, or electrodeionization. Combinations of a number of these processes have come into use to produce ultrapure water of such high purity that its trace contaminants are measured in parts per billion (ppb) or parts per trillion (ppt).

Water softening is the removal of calcium, magnesium, and certain other metal cations in hard water. The resulting soft water requires less soap for the same cleaning effort, as soap is not wasted bonding with calcium ions. Soft water also extends the lifetime of plumbing by reducing or eliminating scale build-up in pipes and fittings. Water softening is usually achieved using lime softening or ion-exchange resins but is increasingly being accomplished using nanofiltration or reverse osmosis membranes.

Ion exchange is a reversible interchange of one kind of ion present in an insoluble solid with another of like charge present in a solution surrounding the solid with the reaction being used especially for softening or making water demineralised, the purification of chemicals and separation of substances.

Fouling is the accumulation of unwanted material on solid surfaces. The fouling materials can consist of either living organisms (biofouling) or a non-living substance. Fouling is usually distinguished from other surface-growth phenomena in that it occurs on a surface of a component, system, or plant performing a defined and useful function and that the fouling process impedes or interferes with this function.

Ferrosilicon is an alloy of iron and silicon with a typical silicon content by weight of 15–90%. It contains a high proportion of iron silicides.

There are many uses of water in industry and, in most cases, the used water also needs treatment to render it fit for re-use or disposal. Raw water entering an industrial plant often needs treatment to meet tight quality specifications to be of use in specific industrial processes. Industrial water treatment encompasses all these aspects which include industrial wastewater treatment, boiler water treatment and cooling water treatment.

A condensate polisher is a device used to filter water condensed from steam as part of the steam cycle, for example in a conventional or nuclear power plant. It is frequently filled with polymer resins which are used to remove or exchange ions such that the purity of the condensate is maintained at or near that of distilled water.

Boiler feedwater is an essential part of boiler operations. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used, it is then dumped to the main condenser. From the condenser, it is then pumped to the deaerated feed tank. From this tank it then goes back to the steam drum to complete its cycle. The feedwater is never open to the atmosphere. This cycle is known as a closed system or Rankine cycle.

The dealkalization of water refers to the removal of alkalinity ions from water. Chloride cycle anion ion-exchange dealkalizers remove alkalinity from water.

Lime softening is a type of water treatment used for water softening, which uses the addition of limewater to remove hardness by precipitation. The process is also effective at removing a variety of microorganisms and dissolved organic matter by flocculation.

Boiler blowdown is water intentionally wasted from a boiler to avoid concentration of impurities during continuing evaporation of steam. The water is blown out of the boiler with some force by steam pressure within the boiler. Bottom blowdown used with early boilers caused abrupt downward adjustment of boiler water level and was customarily expelled downward to avoid the safety hazard of showering hot water on nearby individuals.

The residual sodium carbonate (RSC) index of irrigation water or soil water is used to indicate the alkalinity hazard for soil. The RSC index is used to find the suitability of the water for irrigation in clay soils which have a high cation exchange capacity. When dissolved sodium in comparison with dissolved calcium and magnesium is high in water, clay soil swells or undergoes dispersion which drastically reduces its infiltration capacity.

Steam and water analysis system (SWAS) is a system dedicated to the analysis of steam or water. In power stations, it is usually used to analyze boiler steam and water to ensure the water used to generate electricity is clean from impurities which can cause corrosion to any metallic surface, such as in boiler and turbine.