A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

Water cooling is a method of heat removal from components and industrial equipment. Evaporative cooling using water is often more efficient than air cooling. Water is inexpensive and non-toxic; however, it can contain impurities and cause corrosion.

Main components found on a typical steam locomotive include:

A fire-tube boiler is a type of boiler invented in 1828 by Mark Seguin, in which hot gases pass from a fire through one or more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.

Hydronics is the use of liquid water or gaseous water (steam) or a water solution as a heat-transfer medium in heating and cooling systems. The name differentiates such systems from oil and refrigerant systems.

A thermal power station, also known as a thermal power plant, is a type of power station in which the heat energy generated from various fuel sources is converted to electrical energy. The combustion or nuclear reaction of the fuel source in a boiler or reactor generates heat, which is converted into mechanical energy using a thermodynamic power cycle, where a working fluid is heated and boiled under immense pressure in a large pressure vessel to produce high-pressure steam. This high pressure-steam is then directed to a turbine through a series of pipes, where the force of the steam rotates the turbine's blades. The rotating turbine, which is mechanically connected to an electric generator, turns the generator's rotor with conductive coils. A stationary magnetic field interacts with rotating coils to produce electricity in them via electromagnetic induction. Fuels such as natural gas or oil can also be burnt directly in gas turbines. These plants can be of the open cycle or the more efficient combined cycle type.

A deaerator is a device that is used for the removal of dissolved gases like oxygen from a liquid.

Fouling is the accumulation of unwanted material on solid surfaces. The fouling materials can consist of either living organisms or a non-living substance (inorganic). Fouling is usually distinguished from other surface-growth phenomena in that it occurs on a surface of a component, system, or plant performing a defined and useful function and that the fouling process impedes or interferes with this function.

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid state at a pressure below atmospheric pressure. Where cooling water is in short supply, an air-cooled condenser is often used. An air-cooled condenser is however, significantly more expensive and cannot achieve as low a steam turbine exhaust pressure as a water-cooled surface condenser.

There are many uses of water in industry and, in most cases, the used water also needs treatment to render it fit for re-use or disposal. Raw water entering an industrial plant often needs treatment to meet tight quality specifications to be of use in specific industrial processes. Industrial water treatment encompasses all these aspects which include industrial wastewater treatment, boiler water treatment and cooling water treatment.

Boiler water is liquid water within a boiler, or in associated piping, pumps and other equipment, that is intended for evaporation into steam. The term may also be applied to raw water intended for use in boilers, treated boiler feedwater, steam condensate being returned to a boiler, or boiler blowdown being removed from a boiler.

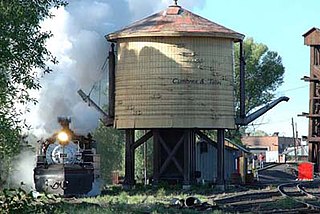

A steam generator is a type of boiler used to produce steam for climate control and potable water heating in railroad passenger cars. The output of a railroad steam generator is low pressure, saturated steam that is passed through a system of pipes and conduits throughout the length of the train.

Economizers, or economisers (UK), are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, power plant, heating, refrigeration, ventilating, and air conditioning (HVAC) may all use economizers. In simple terms, an economizer is a heat exchanger.

Boiler feedwater is the water which is supplied to a boiler. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used, it is then dumped to the main condenser. From the condenser, it is then pumped to the deaerated feed tank. From this tank it then goes back to the steam drum to complete its cycle. The feedwater is never open to the atmosphere. This cycle is known as a closed system or Rankine cycle.

A boiler or steam generator is a device used to create steam by applying heat energy to water. Although the definitions are somewhat flexible, it can be said that older steam generators were commonly termed boilers and worked at low to medium pressure but, at pressures above this, it is more usual to speak of a steam generator.

Priming is a condition in the boiler of a steam locomotive in which water is carried over into the steam delivery. It may be caused by impurities in the water, which foams up as it boils, or simply too high a water level. It is harmful to the valves and pistons, as lubrication is washed away, and can be dangerous as any water collecting in the cylinders is not compressible and if trapped may fracture the cylinder head or piston.

The dealkalization of water refers to the removal of alkalinity ions from water. Chloride cycle anion ion-exchange dealkalizers remove alkalinity from water.

Radiators and convectors are heat exchangers designed to transfer thermal energy from one medium to another for the purpose of space heating.

Boilers for generating steam or hot water have been designed in countless shapes, sizes and configurations. An extensive terminology has evolved to describe their common features. This glossary provides definitions for these terms.

Steam and water analysis system (SWAS) is a system dedicated to the analysis of steam or water. In power stations, it is usually used to analyze boiler steam and water to ensure the water used to generate electricity is clean from impurities which can cause corrosion to any metallic surface, such as in boiler and turbine.