Filtration is a physical separation process that separates solid matter and fluid from a mixture using a filter medium that has a complex structure through which only the fluid can pass. Solid particles that cannot pass through the filter medium are described as oversize and the fluid that passes through is called the filtrate. Oversize particles may form a filter cake on top of the filter and may also block the filter lattice, preventing the fluid phase from crossing the filter, known as blinding. The size of the largest particles that can successfully pass through a filter is called the effective pore size of that filter. The separation of solid and fluid is imperfect; solids will be contaminated with some fluid and filtrate will contain fine particles. Filtration occurs both in nature and in engineered systems; there are biological, geological, and industrial forms. In everyday usage the verb "strain" is more often used; for example, using a colander to drain cooking water from cooked pasta.

Wastewater treatment is a process which removes and eliminates contaminants from wastewater. It thus converts it into an effluent that can be returned to the water cycle. Once back in the water cycle, the effluent creates an acceptable impact on the environment. It is also possible to reuse it. This process is called water reclamation. The treatment process takes place in a wastewater treatment plant. There are several kinds of wastewater which are treated at the appropriate type of wastewater treatment plant. For domestic wastewater the treatment plant is called a Sewage Treatment. Municipal wastewater or sewage are other names for domestic wastewater. For industrial wastewater, treatment takes place in a separate Industrial wastewater treatment, or in a sewage treatment plant. In the latter case it usually follows pre-treatment. Further types of wastewater treatment plants include Agricultural wastewater treatment and leachate treatment plants.

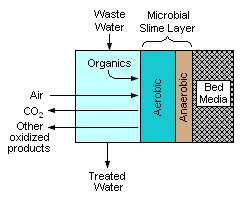

Biofiltration is a pollution control technique using a bioreactor containing living material to capture and biologically degrade pollutants. Common uses include processing waste water, capturing harmful chemicals or silt from surface runoff, and microbiotic oxidation of contaminants in air. Industrial biofiltration can be classified as the process of utilizing biological oxidation to remove volatile organic compounds, odors, and hydrocarbons.

A constructed wetland is an artificial wetland to treat sewage, greywater, stormwater runoff or industrial wastewater. It may also be designed for land reclamation after mining, or as a mitigation step for natural areas lost to land development. Constructed wetlands are engineered systems that use the natural functions of vegetation, soil, and organisms to provide secondary treatment to wastewater. The design of the constructed wetland has to be adjusted according to the type of wastewater to be treated. Constructed wetlands have been used in both centralized and decentralized wastewater systems. Primary treatment is recommended when there is a large amount of suspended solids or soluble organic matter.

The activated sludgeprocess is a type of biological wastewater treatment process for treating sewage or industrial wastewaters using aeration and a biological floc composed of bacteria and protozoa. It is one of several biological wastewater treatment alternatives in secondary treatment, which deals with the removal of biodegradable organic matter and suspended solids. It uses air and microorganisms to biologically oxidize organic pollutants, producing a waste sludge containing the oxidized material.

An aerated lagoon is a simple wastewater treatment system consisting of a pond with artificial aeration to promote the biological oxidation of wastewaters.

Sand filters are used as a step in the water treatment process of water purification.

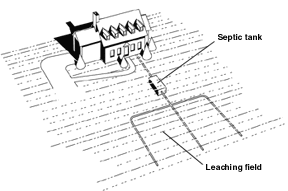

Septic drain fields, also called leach fields or leach drains, are subsurface wastewater disposal facilities used to remove contaminants and impurities from the liquid that emerges after anaerobic digestion in a septic tank. Organic materials in the liquid are catabolized by a microbial ecosystem.

Onsite sewage facilities (OSSF), also called septic systems, are wastewater systems designed to treat and dispose of effluent on the same property that produces the wastewater, in areas not served by public sewage infrastructure.

Secondary treatment is the removal of biodegradable organic matter from sewage or similar kinds of wastewater. The aim is to achieve a certain degree of effluent quality in a sewage treatment plant suitable for the intended disposal or reuse option. A "primary treatment" step often precedes secondary treatment, whereby physical phase separation is used to remove settleable solids. During secondary treatment, biological processes are used to remove dissolved and suspended organic matter measured as biochemical oxygen demand (BOD). These processes are performed by microorganisms in a managed aerobic or anaerobic process depending on the treatment technology. Bacteria and protozoa consume biodegradable soluble organic contaminants while reproducing to form cells of biological solids. Secondary treatment is widely used in sewage treatment and is also applicable to many agricultural and industrial wastewaters.

Sewage sludge treatment describes the processes used to manage and dispose of sewage sludge produced during sewage treatment. Sludge treatment is focused on reducing sludge weight and volume to reduce transportation and disposal costs, and on reducing potential health risks of disposal options. Water removal is the primary means of weight and volume reduction, while pathogen destruction is frequently accomplished through heating during thermophilic digestion, composting, or incineration. The choice of a sludge treatment method depends on the volume of sludge generated, and comparison of treatment costs required for available disposal options. Air-drying and composting may be attractive to rural communities, while limited land availability may make aerobic digestion and mechanical dewatering preferable for cities, and economies of scale may encourage energy recovery alternatives in metropolitan areas.

Aerobic granular reactors (AGR) or Aerobic granular sludge (AGS) are a community of microbial organisms, typically around 0.5-3mm in diameter, that remove carbon, nitrogen, phosphorus and other pollutants in a single sludge system. It can also be used for wastewater treatments. Aerobic granular sludge is composed of bacteria, protozoa and fungi, which allows oxygen to follow in and biologically oxidize organic pollutants. AGS is a type of wastewater treatment process for sewages and/or industrial waste treatment. AGR was first discovered by UK engineers, Edward Ardern and W.T. Lockett who were researching better ways for sewage disposal. Another scientist by the name of Dr. Gilbert Fowler, who was at the University of Manchester working on an experiment based on aeration of sewage in a bottle coated with algae. Eventually, all three scientists were able to collaborate with one another to discover AGR/AGS.

An aerobic treatment system (ATS), often called an aerobic septic system, is a small scale sewage treatment system similar to a septic tank system, but which uses an aerobic process for digestion rather than just the anaerobic process used in septic systems. These systems are commonly found in rural areas where public sewers are not available, and may be used for a single residence or for a small group of homes.

A mound system is an engineered drain field for treating wastewater in places with limited access to multi-stage wastewater treatment systems. Mound systems are an alternative to the traditional rural septic system drain field. They are used in areas where septic systems are prone to failure from extremely permeable or impermeable soils, soil with the shallow cover over porous bedrock, and terrain that features a high water table.

Sewage treatment is a type of wastewater treatment which aims to remove contaminants from sewage to produce an effluent that is suitable to discharge to the surrounding environment or an intended reuse application, thereby preventing water pollution from raw sewage discharges. Sewage contains wastewater from households and businesses and possibly pre-treated industrial wastewater. There are a high number of sewage treatment processes to choose from. These can range from decentralized systems to large centralized systems involving a network of pipes and pump stations which convey the sewage to a treatment plant. For cities that have a combined sewer, the sewers will also carry urban runoff (stormwater) to the sewage treatment plant. Sewage treatment often involves two main stages, called primary and secondary treatment, while advanced treatment also incorporates a tertiary treatment stage with polishing processes and nutrient removal. Secondary treatment can reduce organic matter from sewage, using aerobic or anaerobic biological processes. A so-called quarternary treatment step can also be added for the removal of organic micropollutants, such as pharmaceuticals. This has been implemented in full-scale for example in Sweden.

The biological treatment of wastewater in the sewage treatment plant is often accomplished using conventional activated sludge systems. These systems generally require large surface areas for treatment and biomass separation units due to the generally poor settling properties of the sludge. Aerobic granules are a type of sludge that can self-immobilize flocs and microorganisms into spherical and strong compact structures. The advantages of aerobic granular sludge are excellent settleability, high biomass retention, simultaneous nutrient removal and tolerance to toxicity. Recent studies show that aerobic granular sludge treatment could be a potentially good method to treat high strength wastewaters with nutrients, toxic substances.

A rotating biological contactor or RBC is a biological fixed-film treatment process used in the secondary treatment of wastewater following primary treatment. The primary treatment process involves removal of grit, sand and coarse suspended material through a screening process, followed by settling of suspended solids. The RBC process allows the wastewater to come in contact with a biological film in order to remove pollutants in the wastewater before discharge of the treated wastewater to the environment, usually a body of water. A rotating biological contactor is a type of secondary (biological) treatment process. It consists of a series of closely spaced, parallel discs mounted on a rotating shaft which is supported just above the surface of the wastewater. Microorganisms grow on the surface of the discs where biological degradation of the wastewater pollutants takes place.

A vermifilter is an aerobic treatment system, consisting of a biological reactor containing media that filters organic material from wastewater. The media also provides a habitat for aerobic bacteria and composting earthworms that purify the wastewater by removing pathogens and oxygen demand. The "trickling action" of the wastewater through the media dissolves oxygen into the wastewater, ensuring the treatment environment is aerobic for rapid decomposition of organic substances.

Moving bed biofilm reactor (MBBR) is a type of wastewater treatment process that was first invented by Professor Hallvard Ødegaard at Norwegian University of Science and Technology in the late 1980s. The process takes place in an aeration tank with plastic carriers that a biofilm can grow on. The compact size and cheap wastewater treatment costs offers many advantages for the system. The main objective of using MBBR being water reuse and nutrient removal or recovery. In theory, wastewater will be no longer considered waste, it can be considered a resource.