A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

A fire-tube boiler is a type of boiler invented in 1828 by Mark Seguin, in which hot gases pass from a fire through one or more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.

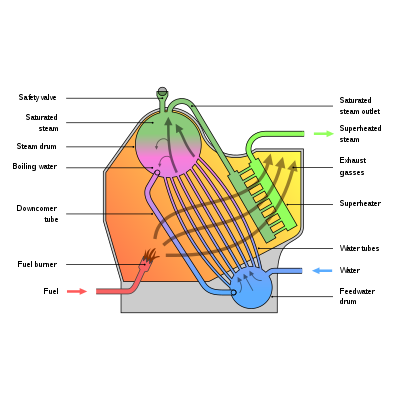

A high pressure watertube boiler is a type of boiler in which water circulates in tubes heated externally by the fire. Fuel is burned inside the furnace, creating hot gas which boils water in the steam-generating tubes. In smaller boilers, additional generating tubes are separate in the furnace, while larger utility boilers rely on the water-filled tubes that make up the walls of the furnace to generate steam.

A heat recovery steam generator (HRSG) is an energy recovery heat exchanger that recovers heat from a hot gas stream, such as a combustion turbine or other waste gas stream. It produces steam that can be used in a process (cogeneration) or used to drive a steam turbine.

A thermal power station is a type of power station in which heat energy is converted to electrical energy. In a steam-generating cycle heat is used to boil water in a large pressure vessel to produce high-pressure steam, which drives a steam turbine connected to an electrical generator. The low-pressure exhaust from the turbine enters a steam condenser where it is cooled to produce hot condensate which is recycled to the heating process to generate more high pressure steam. This is known as a Rankine cycle.

Cockenzie power station was a coal-fired power station in East Lothian, Scotland. It was situated on the south shore of the Firth of Forth, near the town of Cockenzie and Port Seton, 8 mi (13 km) east of the Scottish capital of Edinburgh. The station dominated the local coastline with its distinctive twin chimneys from 1967 until the chimneys' demolition in September 2015. Initially operated by the nationalised South of Scotland Electricity Board, it was operated by Scottish Power following the privatisation of the industry in 1991. In 2005 a WWF report named Cockenzie as the UK's least carbon-efficient power station, in terms of carbon dioxide released per unit of energy generated.

The steam-electric power station is a power station in which the electric generator is steam driven. Water is heated, turns into steam and spins a steam turbine which drives an electrical generator. After it passes through the turbine, the steam is condensed in a condenser. The greatest variation in the design of steam-electric power plants is due to the different fuel sources.

A boiler or steam generator is a device used to create steam by applying heat energy to water. Although the definitions are somewhat flexible, it can be said that older steam generators were commonly termed boilers and worked at low to medium pressure but, at pressures above this, it is more usual to speak of a steam generator.

Kingsnorth power station was a dual-fired coal and oil power station on the Hoo Peninsula at Medway in Kent, South East England. The four-unit station was operated by energy firm E.ON UK, and had a generating capacity of 2,000 megawatts. It was capable of operating on either coal or oil, though in practice oil was used only as a secondary fuel or for startup. It was also capable of co-firing biofuel, up to a maximum of 10% of the station's fuel mix. A replacement power station, also coal-fired, was considered by owners E.ON, but plans were abandoned. The proposed replacement attracted substantial public protests and criticism, including the 2008 Camp for Climate Action.

High Marnham Power Station was a coal fuelled power station in Nottinghamshire, to the west of the River Trent, approximately 0.5 miles (0.8 km) north of the village of Marnham. Construction site clearance began in November 1955, No. 1 Unit power generation commenced in October 1959, and the station became fully operational in June 1962. The plant operated until 2003 when it was decommissioned, though the cooling towers weren't demolished until 2012.

Yarrow boilers are an important class of high-pressure water-tube boilers. They were developed by Yarrow & Co. (London), Shipbuilders and Engineers and were widely used on ships, particularly warships.

The Stirling boiler is an early form of water-tube boiler, used to generate steam in large land-based stationary plants. Although widely used around 1900, it has now fallen from favour and is rarely seen.

Boilers for generating steam or hot water have been designed in countless shapes, sizes and configurations. An extensive terminology has evolved to describe their common features. This glossary provides definitions for these terms.

Three-drum boilers are a class of water-tube boiler used to generate steam, typically to power ships. They are compact and of high evaporative power, factors that encourage this use. Other boiler designs may be more efficient, although bulkier, and so the three-drum pattern was rare as a land-based stationary boiler.

A forced circulation boiler is a boiler where a pump is used to circulate water inside the boiler. This differs from a natural circulation boiler which relies on current density to circulate water inside the boiler. In some forced circulation boilers, the water is circulated at twenty times the rate of evaporation.

A cornertube boiler is a type of natural circulation water-tube boiler which differentiates itself from other water tube boilers by its characteristic water-steam cycle and a pre-separation of heated steam from the steam-water mixture occurs outside the drum and the unheated downcomers.

A LaMont boiler is a type of forced circulation water-tube boiler in which the boiler water is circulated through an external pump through long closely spaced tubes of small diameter. The mechanical pump is employed in order to have an adequate and positive circulation in steam and hot water boilers.

A package boiler is a factory-made boiler. Package boilers are available in a range of standard designs. Package boilers are used for heating and act as a steam generator for small power purposes such as self-powered industrial plants. Package boilers are low pressure designs. A low pressure means low temperature water in the heat exchanger. The large difference between the flame temperature and the heat exchanger discards most of the available entropy. Discarding most of the entropy caps the thermodynamic efficiency below the range needed to make a low pressure boiler suitable for a co-generation plants even when the available capacity is adequate for the application. Advantages of package boilers are that they can be delivered and installed as a complete insulated assembly that doesn’t require a large exclusion zone around itself. The required steam, water, fuel, and electrical connections can be made rapidly. These boilers are inexpensive to operate because their automatic burner management system doesn’t require continuous supervision and they have low scheduled maintenance costs.

Butibori Power Project is a coal-based thermal power plant located at Butibori near Nagpur in the Indian state of Maharashtra. The power plant is operated by the Reliance Power.

The Fairbairn-Beeley boiler was a design of fire-tube stationary boiler developed in the late 19th century. It takes its name from its two developers, Sir William Fairbairn and Thomas Beeley