A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

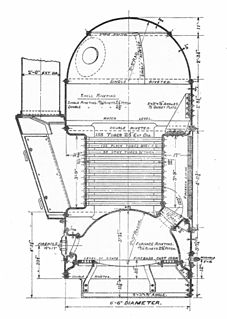

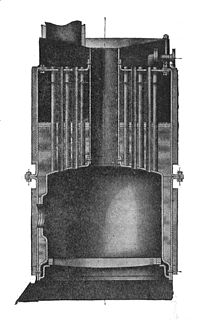

A fire-tube boiler is a type of boiler in which hot gases pass from a fire through one or more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.

A high pressure watertube boiler is a type of boiler in which water circulates in tubes heated externally by the fire. Fuel is burned inside the furnace, creating hot gas which boils water in the steam-generating tubes. In smaller boilers, additional generating tubes are separate in the furnace, while larger utility boilers rely on the water-filled tubes that make up the walls of the furnace to generate steam.

In a steam engine, the firebox is the area where the fuel is burned, producing heat to boil the water in the boiler. Most are somewhat box-shaped, hence the name. The hot gases generated in the firebox are pulled through a rack of tubes running through the boiler.

Thermic siphons are heat-exchanging elements in the firebox or combustion chamber of some steam boiler and steam locomotive designs. As they are directly exposed to the radiant heat of combustion, they have a high evaporative capacity relative to their size. By arranging them near-vertically, they also have good water circulation by means of the thermosyphon effect.

A boiler or steam generator is a device used to create steam by applying heat energy to water. Although the definitions are somewhat flexible, it can be said that older steam generators were commonly termed boilers and worked at low to medium pressure but, at pressures above this, it is more usual to speak of a steam generator.

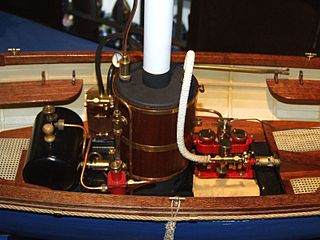

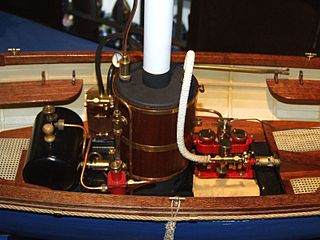

A vertical boiler is a type of fire-tube or water-tube boiler where the boiler barrel is oriented vertically instead of the more common horizontal orientation. Vertical boilers were used for a variety of steam-powered vehicles and other mobile machines, including early steam locomotives.

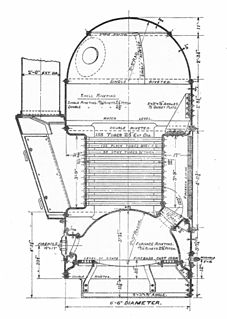

A "Scotch" marine boiler is a design of steam boiler best known for its use on ships.

A shell or flued boiler is an early and relatively simple form of boiler used to make steam, usually for the purpose of driving a steam engine. The design marked a transitional stage in boiler development, between the early haystack boilers and the later multi-tube fire-tube boilers. A flued boiler is characterized by a large cylindrical boiler shell forming a tank of water, traversed by one or more large flues containing the furnace. These boilers appeared around the start of the 19th century and some forms remain in service today. Although mostly used for static steam plants, some were used in early steam vehicles, railway locomotives and ships.

A vertical boiler with horizontal fire-tubes is a type of small vertical boiler, used to generate steam for small machinery. It is characterised by having many narrow fire-tubes, running horizontally.

Yarrow boilers are an important class of high-pressure water-tube boilers. They were developed by Yarrow & Co. (London), Shipbuilders and Engineers and were widely used on ships, particularly warships.

Boilers for generating steam or hot water have been designed in countless shapes, sizes and configurations. An extensive terminology has evolved to describe their common features. This glossary provides definitions for these terms.

A Field-tube boiler is a form of water-tube boiler where the water tubes are single-ended. The tubes are closed at one end, and they contain a concentric inner tube. Flow is thus separated into the colder inner flow down the tube and the heated flow upwards through the outer sleeve. As Field tubes are thus dependent on thermo-syphon flow within the tube, they must thus always have some vertical height to encourage the flow. In most designs they are mounted near-vertically, to encourage this.

The Sentinel boiler was a design of vertical boiler, fitted to the numerous steam wagons built by the Sentinel Waggon Works.

Three-drum boilers are a class of water-tube boiler used to generate steam, typically to power ships. They are compact and of high evaporative power, factors that encourage this use. Other boiler designs may be more efficient, although bulkier, and so the three-drum pattern was rare as a land-based stationary boiler.

A transverse boiler is a boiler used to generate steam to power a vehicle. Unlike other boilers, its external drum is mounted transversely across the vehicle.

A vertical fire-tube boiler or vertical multitubular boiler is a vertical boiler where the heating surface is composed of multiple small fire-tubes, arranged vertically.

A launch-type, gunboat or horizontal multitubular boiler is a form of small steam boiler. It consists of a cylindrical horizontal shell with a cylindrical furnace and fire-tubes within this.

A thimble tube boiler is a form of steam boiler, usually provided as an auxiliary boiler or heat-recovery boiler. They are vertical in orientation and would be considered a form of water-tube boiler.

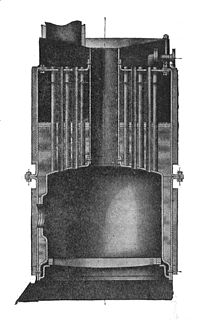

The Fairbairn-Beeley boiler was a design of fire-tube stationary boiler developed in the late 19th century. It takes its name from its two developers, Sir William Fairbairn and Thomas Beeley