Related Research Articles

In commerce, supply chain management (SCM) deals with a system of procurement, operations management, logistics and marketing channels, through which raw materials can be developed into finished products and delivered to their end customers. A more narrow definition of supply chain management is the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally". This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain.

Procurement is the process of locating and agreeing to terms and purchasing goods, services, or other works from an external source, often with the use of a tendering or competitive bidding process. The term may also refer to a contractual obligation to "procure", i.e. to "ensure" that something is done. When a government agency buys goods or services through this practice, it is referred to as government procurement or public procurement.

Critical success factor (CSF) is a management term for an element necessary for an organization or project to achieve its mission. To achieve their goals they need to be aware of each key success factor (KSF) and the variations between the keys and the different roles key result area (KRA).

Business-to-business refers to trade and commercial activity where a business sees other businesses as its customer base. This typically occurs when:

Strategic sourcing is the process of developing channels of supply at the lowest total cost, not just the lowest purchase price. It expands upon traditional organisational purchasing activities to embrace all activities within the procurement cycle, from specification to receipt, payment for goods and services to sourcing production lines where the labor market would increase firms' ROI. Strategic sourcing processes aim for continuous improvement and re-evaluation of the purchasing activities of an organisation.

Supplier relationship management (SRM) is the systematic, enterprise-wide assessment of suppliers' strengths, performance and capabilities with respect to overall business strategy, determination of what activities to engage in with different suppliers, and planning and execution of all interactions with suppliers, in a coordinated fashion across the relationship life cycle, to maximize the value realized through those interactions. The focus of supplier relationship management is the development of two-way, mutually beneficial relationships with strategic supply partners to deliver greater levels of innovation and competitive advantage than could be achieved by operating independently or through a traditional, transactional purchasing arrangement. Underpinning disciplines which support effective SRM include supplier information management, compliance, risk management and performance management.

Category management is a retailing and purchasing concept in which the range of products purchased by a business organization or sold by a retailer is broken down into discrete groups of similar or related products. These groups are known as product categories. It is a systematic, disciplined approach to managing a product category as a strategic business unit. The phrase "category management" was coined by Brian F. Harris.

Industrial marketing or business-to-business marketing is the marketing of goods and services by one business to another. Industrial goods are those an industry uses to produce an end product from one or more raw material. The term industrial marketing has largely been replaced by the term business-to-business marketing (B2B).

Industrial market segmentation is a scheme for categorizing industrial and business customers to guide strategic and tactical decision-making. Government agencies and industry associations use standardized segmentation schemes for statistical surveys. Most businesses create their own segmentation scheme to meet their particular needs. Industrial market segmentation is important in sales and marketing.

A chief procurement officer (CPO) undertakes an executive role within an enterprise, focusing on sourcing, procurement, and supply management.

Global sourcing is the practice of sourcing from the global market for goods and services across geopolitical boundaries. Global sourcing often aims to exploit global efficiencies in the delivery of a product or service. These efficiencies include low cost skilled labor, low cost raw material, extreme international competition, new technology and other economic factors like tax breaks and low trade tariffs. Common examples of globally sourced products or services include labor-intensive manufactured products produced using low-cost Chinese labor, call centers staffed with low-cost English speaking workers in the Philippines, India and Pakistan, and IT work performed by low-cost programmers in India, Pakistan and Eastern Europe. While these are examples of low-cost country sourcing, global sourcing is not limited to low-cost countries.

Commercial management is overseeing and handling an organization’s functions and activities involved in the process of exchanging goods, services, or other valuable assets, as well as any income-generating activity; in order to achieve and sustain profitability while minimizing risks and costs. In other words, commercial management is "the identification and development of business opportunities and the profitable management of projects and contracts, from inception to completion".

Forward Commitment Procurement (FCP) is a procurement model designed to be used to deliver cost-effective environmental products and services to the public sector and help to create the market conditions in which the environmental goods and services sector can thrive.

Digital transformation (DT) is the process of adoption and implementation of digital technology by an organization in order to create new or modify existing products, services and operations by the means of translating business processes into a digital format.

Cost reduction is the process used by organisations aiming to reduce their costs and increase their profits, or to accommodate reduced income. Depending on a company’s services or products, the strategies can vary. Every decision in the product development process affects cost: design is typically considered to account for 70–80% of the final cost of a project such as an engineering project or the construction of a building. In the public sector, cost reduction programs can be used where income is reduced or to reduce debt levels.

Indirect procurement is the sourcing of goods and services not related to manufacturing for a business to enable it to maintain and develop its operations. The goods and services classified under the umbrella of indirect procurement are commonly bought for consumption by internal stakeholders rather than the external customer or client.

Market Dojo is an e-Procurement software company based in Stonehouse, England. The company was established in 2010 by Nick Drewe, Alun Rafique, and Nic Martin. Alun previously worked at Rolls-Royce before meeting Nick Drewe at Vendigital, whilst Nic Martin came from Attensity. All three co-founders studied at Bristol University. The company's competitors include Ariba, Curtis Fitch, and Scan market amongst others.

In commerce, global supply-chain management is defined as the distribution of goods and services throughout a trans-national companies' global network to maximize profit and minimize waste. Essentially, global supply chain-management is the same as supply-chain management, but it focuses on companies and organizations that are trans-national.

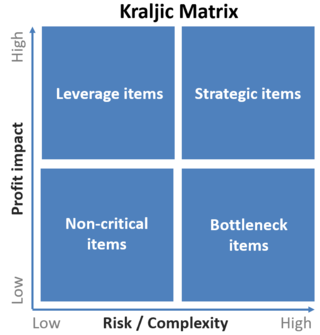

In supply chain management, the Kraljic matrix is a method used to segment the purchases or suppliers of a company by dividing them into four classes, based on the complexity of the supply market and the importance of the purchases or suppliers. This subdivision allows the company to define the optimal purchasing strategies for each of the four types of purchases or suppliers.

At around £290 billion every year, public sector procurement accounts for around a third of all public expenditure in the UK. EU-based laws continue to apply to government procurement: procurement is governed by the Public Contracts Regulations 2015, Part 3 of the Small Business, Enterprise and Employment Act 2015, and the Public Contracts (Scotland) Regulations of 2015 and 2016. These regulations implement EU law, which applied in the UK prior to Brexit, and also contain rules known as the "Lord Young Rules" promoting access for small and medium enterprise (SMEs) to public sector contracts, based on Lord Young's Review Growing Your Business, published in 2013.

References

- ↑ Whitaker, John (May 2013). "Category Management in Purchasing". Supply Management. 18 (5): 50.

- ↑ "Five Best Practices for Category Management", Justin Falgione et al., Inside Supply Management, August 2008

- ↑ CIPS Knowledge Works: Category Management, July 2007

- ↑ Perfect, M., The state of the art of category management - CIPS Australia, published 2019, accessed 23 December 2021

- ↑ O'Brien, J., Category Management in Purchasing, Second Edition (2012), Kogan Page, London, ISBN 978-0-7494-6498-1 E-ESBN 978 0 7494 6499 8

- ↑ "Is Category Management More than Just Strategic Sourcing?". July 2, 2014. Archived from the original on January 8, 2020. Retrieved January 18, 2021.

- ↑ 'Category management explained", Supply Management, 30 January 2003, accessed 26 May 2011.

- 1 2 CIPS. "What is Category Management?". www.cips.org. Retrieved 2023-08-25.

- ↑ CIPS. "What is the Kraljic Matrix?". www.cips.org. Retrieved 2023-08-25.

- ↑ White, T., How to match the right Category Managers to the right categories, CIPS Australasia, published September 2011, accessed 20 November 2022

- ↑ CIPS Australia, The 4th CIPSA Category Management Forum, 6-7 April 2011, Agenda, accessed 20 November 2022

- ↑ Supply Chain Digest, Supply Chain News: The Category Manager and the New Skill Requirements for Procurement Professionals, published 8 September 2010, accessed 4 January 2022

- ↑ Sir Philip Green, Efficiency Review by Sir Philip Green Archived 2010-10-14 at the Wayback Machine , published 11 October 2010, accessed 13 June 2011

- ↑

This article incorporates text published under the British Open Government Licence : Cabinet Office, Making Government business more accessible to SMEs: Two Years On , p. 22, published on 8 August 2013, accessed on 29 December 2024

This article incorporates text published under the British Open Government Licence : Cabinet Office, Making Government business more accessible to SMEs: Two Years On , p. 22, published on 8 August 2013, accessed on 29 December 2024 - ↑ General Services Administration, Guide to Category Management, accessed 27 February 2021

- ↑ Clark, C. S., White House Issues New Guidance on Category Management, accessed 27 February 2021

- ↑ "The Future FAS: Categorically the Right Thing to do for Taxpayers". Archived from the original on 2015-03-15. Retrieved 2015-03-06., accessed 6.3.2015