A real-time operating system (RTOS) is an operating system (OS) for real-time computing applications that processes data and events that have critically defined time constraints. An RTOS is distinct from a time-sharing operating system, such as Unix, which manages the sharing of system resources with a scheduler, data buffers, or fixed task prioritization in a multitasking or multiprogramming environments. Processing time requirements need to be fully understood and bound rather than just kept as a minimum. All processing must occur within the defined constraints. Real-time operating systems are event-driven and preemptive, meaning the OS can monitor the relevant priority of competing tasks, and make changes to the task priority. Event-driven systems switch between tasks based on their priorities, while time-sharing systems switch the task based on clock interrupts.

Project planning is part of project management, which relates to the use of schedules such as Gantt charts to plan and subsequently report progress within the project environment. Project planning can be done manually or by the use of project management software.

Critical chain project management (CCPM) is a method of planning and managing projects that emphasizes the resources required to execute project tasks. It was developed by Eliyahu M. Goldratt. It differs from more traditional methods that derive from critical path and PERT algorithms, which emphasize task order and rigid scheduling. A critical chain project network strives to keep resources levelled, and requires that they be flexible in start times.

Eliyahu Moshe Goldratt was an Israeli business management guru. He was the originator of the Optimized Production Technique, the Theory of Constraints (TOC), the Thinking Processes, Drum-Buffer-Rope, Critical Chain Project Management (CCPM) and other TOC derived tools.

The Project Management Body of Knowledge (PMBOK) is a set of standard terminology and guidelines for project management. The body of knowledge evolves over time and is presented in A Guide to the Project Management Body of Knowledge, a book whose seventh edition was released in 2021. This document results from work overseen by the Project Management Institute (PMI), which offers the CAPM and PMP certifications.

The critical path method (CPM), or critical path analysis (CPA), is an algorithm for scheduling a set of project activities. A critical path is determined by identifying the longest stretch of dependent activities and measuring the time required to complete them from start to finish. It is commonly used in conjunction with the program evaluation and review technique (PERT).

The theory of constraints (TOC) is a management paradigm that views any manageable system as being limited in achieving more of its goals by a very small number of constraints. There is always at least one constraint, and TOC uses a focusing process to identify the constraint and restructure the rest of the organization around it. TOC adopts the common idiom "a chain is no stronger than its weakest link". That means that organizations and processes are vulnerable because the weakest person or part can always damage or break them, or at least adversely affect the outcome.

The thinking processes in Eliyahu M. Goldratt's theory of constraints are the five methods to enable the focused improvement of any cognitive system.

The Goal is a management-oriented novel by Eliyahu M. Goldratt, a business consultant known for his theory of constraints, and Jeff Cox, the author of several management-oriented novels. The Goal was originally published in 1984 and has since been revised and republished. This describes a case study in operations management, focusing on the theory of constraints, and bottlenecks and how to alleviate them. In 2011, Time Magazine listed the book as one of "the 25 most influential business management books".

This is a list of topics related to the theory of constraints.

Throughput accounting (TA) is a principle-based and simplified management accounting approach that provides managers with decision support information for enterprise profitability improvement. TA is relatively new in management accounting. It is an approach that identifies factors that limit an organization from reaching its goal, and then focuses on simple measures that drive behavior in key areas towards reaching organizational goals. TA was proposed by Eliyahu M. Goldratt as an alternative to traditional cost accounting. As such, Throughput Accounting is neither cost accounting nor costing because it is cash focused and does not allocate all costs to products and services sold or provided by an enterprise. Considering the laws of variation, only costs that vary totally with units of output e.g. raw materials, are allocated to products and services which are deducted from sales to determine Throughput. Throughput Accounting is a management accounting technique used as the performance measure in the Theory of Constraints (TOC). It is the business intelligence used for maximizing profits, however, unlike cost accounting that primarily focuses on 'cutting costs' and reducing expenses to make a profit, Throughput Accounting primarily focuses on generating more throughput. Conceptually, Throughput Accounting seeks to increase the speed or rate at which throughput is generated by products and services with respect to an organization's constraint, whether the constraint is internal or external to the organization. Throughput Accounting is the only management accounting methodology that considers constraints as factors limiting the performance of organizations.

In project management, resource leveling is defined by A Guide to the Project Management Body of Knowledge as "A technique in which start and finish dates are adjusted based on resource limitation with the goal of balancing demand for resources with the available supply." Resource leveling problem could be formulated as an optimization problem. The problem could be solved by different optimization algorithms such as exact algorithms or meta-heuristic methods.

The Shifting Bottleneck Heuristic is a procedure intended to minimize the time it takes to do work, or specifically, the makespan in a job shop. The makespan is defined as the amount of time, from start to finish, to complete a set of multi-machine jobs where machine order is pre-set for each job. Assuming that the jobs are actually competing for the same resources (machines) then there will always be one or more resources that act as a 'bottleneck' in the processing. This heuristic, or 'rule of thumb' procedure minimises the effect of the bottleneck. The Shifting Bottleneck Heuristic is intended for job shops with a finite number of jobs and a finite number of machines.

A glossary of terms relating to project management and consulting.

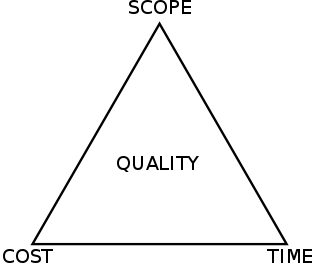

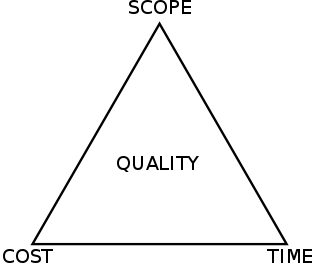

The project management triangle is a model of the constraints of project management. While its origins are unclear, it has been used since at least the 1950s. It contends that:

- The quality of work is constrained by the project's budget, deadlines and scope (features).

- The project manager can trade between constraints.

- Changes in one constraint necessitate changes in others to compensate or quality will suffer.

Total project control (TPC) is a project management method that emphasizes continuous tracking and optimization of return on investment (ROI). It was developed by Stephen Devaux. It builds upon earlier techniques such as earned value management, critical path method, and program evaluation and review technique, but uses these to track and index projected project profitability as well as the more traditional cost and schedule. In this way it aims to manage projects as profit and investment centers, rather than cost centers.

The following outline is provided as an overview of and topical guide to project management:

Schedule Network Analysis is a strategy that is commonly used in project management. The strategy consists of visualising the different project tasks and making connections between them in the project management plan.

Theory of constraints (TOC) is an engineering management technique used to evaluate a manageable procedure, identifying the largest constraint (bottleneck) and strategizing to reduce task time and maximise profit. It assists in determining what to change, when to change it, and how to cause the change. The theory was established by Dr. Eliyahu Goldratt through his 1984 bestselling novel The Goal. Since this time, TOC has continued to develop and evolve and is a primary management tool in the engineering industry. When Applying TOC, powerful tools are used to determine the constraint and reduce its effect on the procedure, including: