Software testing is an investigation conducted to provide stakeholders with information about the quality of the software product or service under test. Software testing can also provide an objective, independent view of the software to allow the business to appreciate and understand the risks of software implementation. Test techniques include the process of executing a program or application with the intent of finding software bugs, and verifying that the software product is fit for use.

Fault tree analysis (FTA) is a top-down, deductive failure analysis in which an undesired state of a system is analyzed using Boolean logic to combine a series of lower-level events. This analysis method is mainly used in the fields of safety engineering and reliability engineering to understand how systems can fail, to identify the best ways to reduce risk or to determine event rates of a safety accident or a particular system level (functional) failure. FTA is used in the aerospace, nuclear power, chemical and process, pharmaceutical, petrochemical and other high-hazard industries; but is also used in fields as diverse as risk factor identification relating to social service system failure. FTA is also used in software engineering for debugging purposes and is closely related to cause-elimination technique used to detect bugs.

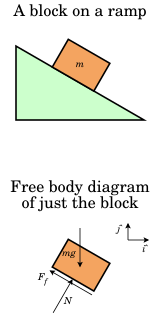

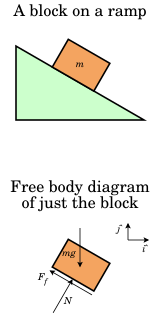

In physics and engineering, a free body diagram is a graphical illustration used to visualize the applied forces, movements, and resulting reactions on a body in a given condition. They depict a body or connected bodies with all the applied forces and moments, and reactions, which act on the body(ies). The body may consist of multiple internal members,, or be a compact body. A series of free bodies and other diagrams may be necessary to solve complex problems.

The systems development life cycle (SDLC), also referred to as the application development life-cycle, is a term used in systems engineering, information systems and software engineering to describe a process for planning, creating, testing, and deploying an information system. The systems development lifecycle concept applies to a range of hardware and software configurations, as a system can be composed of hardware only, software only, or a combination of both. There are usually six stages in this cycle: analysis, design, development and testing, implementation, documentation, and evaluation.

Process engineering is the understanding and application of the fundamental principles and laws of nature that allow us to transform raw material and energy into products that are useful to society, an industrial level. By taking advantage of the driving forces of nature such as pressure, temperature and concentration gradients, as well as the law of conservation of mass, process engineers can develop methods to synthesize and purify large quantities of desired chemical products. Process engineering focuses on the design, operation, control, optimization and intensification of chemical, physical, and biological processes. Process engineering encompasses a vast range of industries, such as agriculture, automotive, biotechnical, chemical, food, material development, mining, nuclear, petrochemical, pharmaceutical, and software development. The application of systematic computer-based methods to process engineering is "process systems engineering".

Design for Six Sigma (DFSS) is a business-process management method related to traditional Six Sigma. It is used in many industries, like finance, marketing, basic engineering, process industries, waste management, and electronics. It is based on the use of statistical tools like linear regression and enables empirical research similar to that performed in other fields, such as social science. While the tools and order used in Six Sigma require a process to be in place and functioning, DFSS has the objective of determining the needs of customers and the business, and driving those needs into the product solution so created. DFSS is relevant for relatively simple items / systems. It is used for product or process design in contrast with process improvement. Measurement is the most important part of most Six Sigma or DFSS tools, but whereas in Six Sigma measurements are made from an existing process, DFSS focuses on gaining a deep insight into customer needs and using these to inform every design decision and trade-off.

Software maintenance in software engineering is the modification of a software product after delivery to correct faults, to improve performance or other attributes.

Reliability engineering is a sub-discipline of systems engineering that emphasizes dependability in the lifecycle management of a product. Dependability, or reliability, describes the ability of a system or component to function under stated conditions for a specified period of time. Reliability is closely related to availability, which is typically described as the ability of a component or system to function at a specified moment or interval of time.

Poka-yoke is a Japanese term that means "mistake-proofing" or "inadvertent error prevention". The key word in the second translation, often omitted, is "inadvertent". There is no poka-yoke solution that protects against an operator's intentional sabotage. A poka-yoke is any mechanism in any process that helps an equipment operator avoid (yokeru) mistakes (poka). Its purpose is to eliminate product defects by preventing, correcting, or drawing attention to human errors as they occur. The concept was formalised, and the term adopted, by Shigeo Shingo as part of the Toyota Production System. It was originally described as baka-yoke, but as this means "fool-proofing" the name was changed to the milder poka-yoke.

Failure analysis is the process of collecting and analyzing data to determine the cause of a failure, often with the goal of determining corrective actions or liability. According to Bloch and Geitner, machinery failures reveal a reaction chain of cause and effect… usually a deficiency commonly referred to as the symptom…”. failure analysis can save money, lives, and resources if done correctly and acted upon. It is an important discipline in many branches of manufacturing industry, such as the electronics industry, where it is a vital tool used in the development of new products and for the improvement of existing products. The failure analysis process relies on collecting failed components for subsequent examination of the cause or causes of failure using a wide array of methods, especially microscopy and spectroscopy. Nondestructive testing (NDT) methods are valuable because the failed products are unaffected by analysis, so inspection sometimes starts using these methods.

A wine fault or defect is an unpleasant characteristic of a wine often resulting from poor winemaking practices or storage conditions, and leading to wine spoilage. Many of the compounds that cause wine faults are already naturally present in wine but at insufficient concentrations to be of issue. In fact, depending on perception, these concentrations may impart positive characters to the wine. However, when the concentration of these compounds greatly exceeds the sensory threshold, they replace or obscure the flavors and aromas that the wine should be expressing. Ultimately the quality of the wine is reduced, making it less appealing and sometimes undrinkable.

In document ISO 10303-226, a fault is defined as an abnormal condition or defect at the component, equipment, or sub-system level which may lead to a failure.

A failure reporting, analysis, and corrective action system (FRACAS) is a system, sometimes carried out using software, that provides a process for reporting, classifying, analyzing failures, and planning corrective actions in response to those failures. It is typically used in an industrial environment to collect data, record and analyze system failures. A FRACAS system may attempt to manage multiple failure reports and produces a history of failure and corrective actions. FRACAS records the problems related to a product or process and their associated root causes and failure analyses to assist in identifying and implementing corrective actions.

In an electric power system, a fault or fault current is any abnormal electric current. For example, a short circuit is a fault in which current bypasses the normal load. An open-circuit fault occurs if a circuit is interrupted by some failure. In three-phase systems, a fault may involve one or more phases and ground, or may occur only between phases. In a "ground fault" or "earth fault", current flows into the earth. The prospective short-circuit current of a predictable fault can be calculated for most situations. In power systems, protective devices can detect fault conditions and operate circuit breakers and other devices to limit the loss of service due to a failure.

Eight disciplines (8Ds) problem solving is a method developed at Ford Motor Company used to approach and to resolve problems, typically employed by engineers or other professionals. Focused on product and process improvement, its purpose is to identify, correct, and eliminate recurring problems. It establishes a permanent corrective action based on statistical analysis of the problem and on the origin of the problem by determining the root causes. Although it originally comprised eight stages, or 'disciplines', it was later augmented by an initial planning stage. 8D follows the logic of the PDCA cycle. The disciplines are:

Dissolved gas analysis (DGA) is the study of dissolved gases in transformer oil.

Value-stream mapping is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from its beginning through to the customer with reduced lean wastes as compared to current map. A value stream focuses on areas of a firm that add value to a product or service, whereas a value chain refers to all of the activities within a company. At Toyota, it is known as "material- and information-flow mapping".

ISO 13406-2 is an ISO standard, with the full title "Ergonomic requirements for work with visual displays based on flat panels -- Part 2: Ergonomic requirements for flat panel displays". It is best known to end consumers for defining a series of flat-panel display "classes" with different numbers of permitted defects. ISO 13406-2 also provides a classification of Viewing Direction Range Classes and Reflection Classes.

In software engineering and hardware engineering, serviceability is one of the -ilities or aspects. It refers to the ability of technical support personnel to install, configure, and monitor computer products, identify exceptions or faults, debug or isolate faults to root cause analysis, and provide hardware or software maintenance in pursuit of solving a problem and restoring the product into service. Incorporating serviceability facilitating features typically results in more efficient product maintenance and reduces operational costs and maintains business continuity.