Computer keyboards can be classified by the switch technology that they use. Computer alphanumeric keyboards typically have 80 to 110 durable switches, generally one for each key. The choice of switch technology affects key response and pre travel. Newer keyboard models use hybrids of various technologies to achieve greater cost savings.

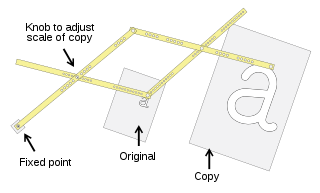

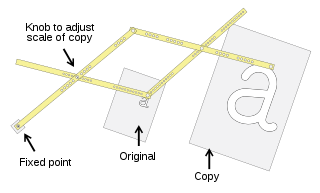

A pantograph is a mechanical linkage connected in a manner based on parallelograms so that the movement of one pen, in tracing an image, produces identical movements in a second pen. If a line drawing is traced by the first point, an identical, enlarged, or miniaturized copy will be drawn by a pen fixed to the other. Using the same principle, different kinds of pantographs are used for other forms of duplication in areas such as sculpture, minting, engraving, and milling.

Solar sails are a proposed method of spacecraft propulsion using radiation pressure exerted by sunlight on large mirrors. A useful analogy may be a sailing boat; the light exerting a force on the mirrors is akin to a sail being blown by the wind. High-energy laser beams could be used as an alternative light source to exert much greater force than would be possible using sunlight, a concept known as beam sailing.

A machine is a mechanical structure that uses power to apply forces and control movement to perform an intended action. Machines can be driven by animals and people, by natural forces such as wind and water, and by chemical, thermal, or electrical power, and include a system of mechanisms that shape the actuator input to achieve a specific application of output forces and movement. They can also include computers and sensors that monitor performance and plan movement, often called mechanical systems.

An end-face mechanical seal, or a mechanical end-face seal, also referred to as a mechanical face seal but usually simply as a mechanical seal, is a type of seal utilised in rotating equipment, such as pumps, mixers, blowers, and compressors. When a pump operates, the liquid could leak out of the pump between the rotating shaft and the stationary pump casing. Since the shaft rotates, preventing this leakage can be difficult. Earlier pump models used mechanical packing to seal the shaft. Since World War II, mechanical seals have replaced packing in many applications.

An automotive sunroof is a movable panel that is operable to uncover an opening in an automobile roof, which allows light and/or fresh air to enter the passenger compartment. Sunroofs are either manually operated or motor driven, and are available in many shapes, sizes and styles. While the term sunroof is now used generically to describe any glass panel in the roof, the term "moonroof" was historically used to describe stationary glass panes rigidly mounted in the roof panel over the passenger compartment. Previous terms include Sunshine Roof, Sliding Head and Sliding Roof.

An active structure is a mechanical structure with the ability to alter its configuration, form or properties in response to changes in the environment.

Chuck Hoberman is an artist, engineer, architect, and inventor of folding toys and structures, most notably the Hoberman sphere.

In physics, the degree of freedom (DOF) of a mechanical system is the number of independent parameters that define its configuration. It is the number of parameters that determine the state of a physical system and is important to the analysis of systems of bodies in mechanical engineering, aeronautical engineering, robotics, and structural engineering.

A linear-motion bearing or linear slide is a bearing designed to provide free motion in one direction. There are many different types of linear motion bearings.

An overconstrained mechanism is a linkage that has more degrees of freedom than is predicted by the mobility formula. The mobility formula evaluates the degree of freedom of a system of rigid bodies that results when constraints are imposed in the form of joints connecting the links.

Harmonic Drive is the brand name of strain wave gear trademarked by the Harmonic Drive company, and invented in 1957 by C.W. Musser.

In mechanical engineering, a kinematic chain is an assembly of rigid bodies connected by joints to provide constrained motion that is the mathematical model for a mechanical system. As in the familiar use of the word chain, the rigid bodies, or links, are constrained by their connections to other links. An example is the simple open chain formed by links connected in series, like the usual chain, which is the kinematic model for a typical robot manipulator.

In engineering, a mechanism is a device that transforms input forces and movement into a desired set of output forces and movement. Mechanisms generally consist of moving components that can include:

Strain wave gearing also known as harmonic gearing is a special type of mechanical gear system that can improve certain characteristics compared to traditional gearing systems such as helical gears or planetary gears. It was invented in 1957 by C.W. Musser while he was a research advisor at United Shoe Machinery (USM). The advantages include: no backlash, compactness and light weight, high gear ratios, reconfigurable ratios within a standard housing, good resolution and excellent repeatability when repositioning inertial loads, high torque capability, and coaxial input and output shafts. High gear reduction ratios are possible in a small volume . Disadvantages include a tendency for 'wind-up' in the low torque region. Strain wave gears are typically used in industrial motion control, machine tool, printing machine, robotics and aerospace, for gear reduction but may also be used to increase rotational speed, or for differential gearing.

Multi-function material is a composite material. The traditional approach to the development of structures is to address the loadcarrying function and other functional requirements separately. Recently, however, there has been increased interest in the development of load-bearing materials and structures which have integral non-load-bearing functions, guided by recent discoveries about how multifunctional biological systems work.

The Roll Out Solar Array, known as ROSA, is a solar array designed by NASA. This new type of solar array provides much more energy than the old solar arrays. Traditional solar panels used to power satellites can be bulky with heavy panels folded together using mechanical hinges. When launching into space, mass and volume are everything, and ROSA is 20 percent lighter and four times smaller in volume than rigid panel arrays. It is a flexible and rollable solar array like a measuring tape wound on its spool. The new solar array design rolls up to form a compact cylinder for launch with significantly less mass and volume, potentially offering substantial cost savings as well as an increase in power for satellites. Being smaller and lighter than the traditional solar panels, ROSA has a center wing made of a flexible material which support the strings of photovoltaic cells that churn out electrical energy. Both the sides of the wing have a narrow arm that extends through the length of the wing to provide support to the array, called a high strain composite boom. The booms look like split tubes made of a stiff composite material, flattened and rolled up lengthwise.The array does not need any motor to unfurl.This is achieved using the energy stored in the booms that is released as each boom transitions from a coil shape to a straight support arm. Those solar wings are then deployed due to strain energy in rolled booms that are present at the two ends of the structure.