A machine is a physical system using power to apply forces and control movement to perform an action. The term is commonly applied to artificial devices, such as those employing engines or motors, but also to natural biological macromolecules, such as molecular machines. Machines can be driven by animals and people, by natural forces such as wind and water, and by chemical, thermal, or electrical power, and include a system of mechanisms that shape the actuator input to achieve a specific application of output forces and movement. They can also include computers and sensors that monitor performance and plan movement, often called mechanical systems.

In computer animation and robotics, inverse kinematics is the mathematical process of calculating the variable joint parameters needed to place the end of a kinematic chain, such as a robot manipulator or animation character's skeleton, in a given position and orientation relative to the start of the chain. Given joint parameters, the position and orientation of the chain's end, e.g. the hand of the character or robot, can typically be calculated directly using multiple applications of trigonometric formulas, a process known as forward kinematics. However, the reverse operation is, in general, much more challenging.

A flexure bearing is a category of flexure which is engineered to be compliant in one or more angular degrees of freedom. Flexure bearings are often part of compliant mechanisms. Flexure bearings serve much of the same function as conventional bearings or hinges in applications which require angular compliance. However, flexures require no lubrication and exhibit very low or no friction.

Topology optimization (TO) is a mathematical method that optimizes material layout within a given design space, for a given set of loads, boundary conditions and constraints with the goal of maximizing the performance of the system. Topology optimization is different from shape optimization and sizing optimization in the sense that the design can attain any shape within the design space, instead of dealing with predefined configurations.

Robot locomotion is the collective name for the various methods that robots use to transport themselves from place to place.

A flexure is a flexible element engineered to be compliant in specific degrees of freedom. Flexures are a design feature used by design engineers for providing adjustment or compliance in a design.

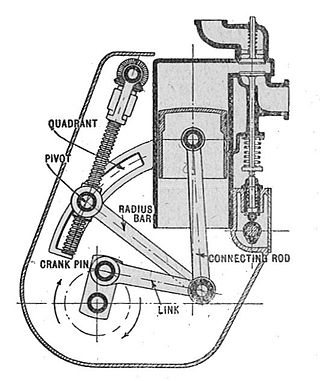

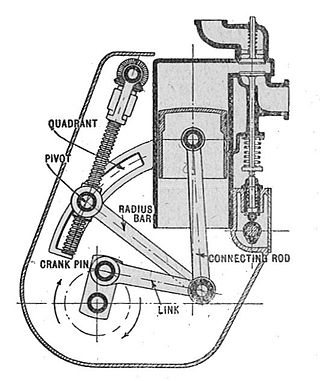

A mechanical linkage is an assembly of systems connected to manage forces and movement. The movement of a body, or link, is studied using geometry so the link is considered to be rigid. The connections between links are modeled as providing ideal movement, pure rotation or sliding for example, and are called joints. A linkage modeled as a network of rigid links and ideal joints is called a kinematic chain.

Vibration isolation is the prevention of transmission of vibration from one component of a system to others parts of the same system, as in buildings or mechanical systems. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems. Vibrations propagate via mechanical waves and certain mechanical linkages conduct vibrations more efficiently than others. Passive vibration isolation makes use of materials and mechanical linkages that absorb and damp these mechanical waves. Active vibration isolation involves sensors and actuators that produce disruptive interference that cancels-out incoming vibration.

A parallel manipulator is a mechanical system that uses several computer-controlled serial chains to support a single platform, or end-effector. Perhaps, the best known parallel manipulator is formed from six linear actuators that support a movable base for devices such as flight simulators. This device is called a Stewart platform or the Gough-Stewart platform in recognition of the engineers who first designed and used them.

Multibody system is the study of the dynamic behavior of interconnected rigid or flexible bodies, each of which may undergo large translational and rotational displacements.

In mechanical engineering, a kinematic chain is an assembly of rigid bodies connected by joints to provide constrained motion that is the mathematical model for a mechanical system. As the word chain suggests, the rigid bodies, or links, are constrained by their connections to other links. An example is the simple open chain formed by links connected in series, like the usual chain, which is the kinematic model for a typical robot manipulator.

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering. Manufacturing engineering requires the ability to plan the practices of manufacturing; to research and to develop tools, processes, machines and equipment; and to integrate the facilities and systems for producing quality products with the optimum expenditure of capital. Transitioning the product to manufacture it in volumes is considered part of product engineering.

In engineering, a mechanism is a device that transforms input forces and movement into a desired set of output forces and movement. Mechanisms generally consist of moving components which may include:

Lamina Emergent Mechanisms are more commonly referred to as "Pop-up Mechanisms" as seen in "pop-up-books". LEM is the technical term of such mechanisms or engineering. LEMs are a subset of compliant mechanisms fabricated from planar materials (lamina) and have motion emerging from the fabrication plane. LEMs use compliance, or the deflection of flexible members to achieve motion.

Larry L. Howell is a professor and Associate Academic Vice President (AAVP) at Brigham Young University (BYU). His research focuses on compliant mechanisms, including origami-inspired mechanisms, microelectromechanical systems, medical devices, space mechanisms, and developable mechanisms. Howell has also conducted research in lamina emergent mechanisms and nanoinjection. He received a bachelor's degree in mechanical engineering from BYU and master's and Ph.D. degrees from Purdue University. His Ph.D. advisor was Ashok Midha, who is regarded as the "Father of Compliant Mechanisms."

Soft robotics is a subfield of robotics that concerns the design, control, and fabrication of robots composed of compliant materials, instead of rigid links. In contrast to rigid-bodied robots built from metals, ceramics and hard plastics, the compliance of soft robots can improve their safety when working in close contact with humans.

Self-adaptive mechanisms, sometimes simply called adaptive mechanisms, in engineering, are underactuated mechanisms that can adapt to their environment. One of the most well-known example of this type of mechanisms are underactuated fingers, grippers, and robotic hands. Contrary to standard underactuated mechanisms where the motion is governed by the dynamics of the system, the motion of self-adaptive mechanisms is generally constrained by compliant elements cleverly located in the mechanisms.

Developable mechanisms are a special class of mechanisms that can be placed on developable surfaces.

Arachnid locomotion is the various means by which arachnids walk, run, or jump; they make use of more than muscle contraction, employing additional methods like hydraulic compression. Another adaptation seen especially in larger arachnid variants is inclusion of elastic connective tissues.

A continuum robot is a type of robot that is characterised by infinite degrees of freedom and number of joints. These characteristics allow continuum manipulators to adjust and modify their shape at any point along their length, granting them the possibility to work in confined spaces and complex environments where standard rigid-link robots cannot operate. In particular, we can define a continuum robot as an actuatable structure whose constitutive material forms curves with continuous tangent vectors. This is a fundamental definition that allows to distinguish between continuum robots and snake-arm robots or hyper-redundant manipulators: the presence of rigid links and joints allows them to only approximately perform curves with continuous tangent vectors.