An oil well is a drillhole boring in Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released as associated petroleum gas along with the oil. A well that is designed to produce only gas may be termed a gas well. Wells are created by drilling down into an oil or gas reserve that is then mounted with an extraction device such as a pumpjack which allows extraction from the reserve. Creating the wells can be an expensive process, costing at least hundreds of thousands of dollars, and costing much more when in hard to reach areas, e.g., when creating offshore oil platforms. The process of modern drilling for wells first started in the 19th century, but was made more efficient with advances to oil drilling rigs during the 20th century.

Roughneck is a term for a person whose occupation is hard manual labor. The term applies across a number of industries, but is most commonly associated with the workers on a drilling rig. The ideal of the hard-working, tough roughneck has been adopted by several sports teams who use the phrase as part of their name or logo.

A mud engineer works on an oil well or gas well drilling rig, and is responsible for ensuring the properties of the drilling fluid, also known as drilling mud, are within designed specifications.

Well control is the technique used in oil and gas operations such as drilling, well workover and well completion for maintaining the hydrostatic pressure and formation pressure to prevent the influx of formation fluids into the wellbore. This technique involves the estimation of formation fluid pressures, the strength of the subsurface formations and the use of casing and mud density to offset those pressures in a predictable fashion. Understanding pressure and pressure relationships is important in well control.

In geotechnical engineering, drilling fluid, also known as drilling mud, is used to aid the drilling of boreholes into the earth. Used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are also used for much simpler boreholes, such as water wells.

Mud logging is the creation of a detailed record of a borehole by examining the cuttings of rock brought to the surface by the circulating drilling medium. Mud logging is usually performed by a third-party mud logging company. This provides well owners and producers with information about the lithology and fluid content of the borehole while drilling. Historically it is the earliest type of well log. Under some circumstances compressed air is employed as a circulating fluid, rather than mud. Although most commonly used in petroleum exploration, mud logging is also sometimes used when drilling water wells and in other mineral exploration, where drilling fluid is the circulating medium used to lift cuttings out of the hole. In hydrocarbon exploration, hydrocarbon surface gas detectors record the level of natural gas brought up in the mud. A mobile laboratory is situated by the mud logging company near the drilling rig or on deck of an offshore drilling rig, or on a drill ship.

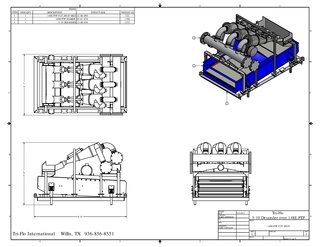

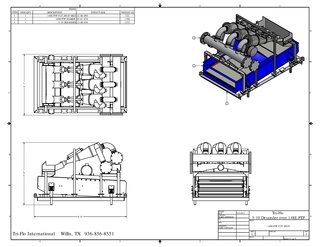

Shale shakers are components of drilling equipment used in many industries, such as coal cleaning, mining, oil and gas drilling.They are the first phase of a solids control system on a drilling rig, and are used to remove large solids (cuttings) from the drilling fluid ("mud").

Petroleum is a fossil fuel that can be drawn from beneath the earth's surface. Reservoirs of petroleum are formed through the mixture of plants, algae, and sediments in shallow seas under high pressure. Petroleum is mostly recovered from oil drilling. Seismic surveys and other methods are used to locate oil reservoirs. Oil rigs and oil platforms are used to drill long holes into the earth to create an oil well and extract petroleum. After extraction, oil is refined to make gasoline and other products such as tires and refrigerators. Extraction of petroleum can be dangerous and have led to oil spills.

In the oil and gas industry, coiled tubing refers to a long metal pipe, normally 1 to 3.25 in in diameter which is supplied spooled on a large reel. It is used for interventions in oil and gas wells and sometimes as production tubing in depleted gas wells. Coiled tubing is often used to carry out operations similar to wirelining. The main benefits over wireline are the ability to pump chemicals through the coil and the ability to push it into the hole rather than relying on gravity. Pumping can be fairly self-contained, almost a closed system, since the tube is continuous instead of jointed pipe. For offshore operations, the 'footprint' for a coiled tubing operation is generally larger than a wireline spread, which can limit the number of installations where coiled tubing can be performed and make the operation more costly. A coiled tubing operation is normally performed through the drilling derrick on the oil platform, which is used to support the surface equipment, although on platforms with no drilling facilities a self-supporting tower can be used instead. For coiled tubing operations on sub-sea wells a mobile offshore drilling unit (MODU) e.g. semi-submersible, drillship etc. has to be utilized to support all the surface equipment and personnel, whereas wireline can be carried out from a smaller and cheaper intervention vessel. Onshore, they can be run using smaller service rigs, and for light operations a mobile self-contained coiled tubing rig can be used.

Oilfield terminology refers to the jargon used by those working in fields within and related to the upstream segment of the petroleum industry. It includes words and phrases describing professions, equipment, and procedures specific to the industry. It may also include slang terms used by oilfield workers to describe the same.

A mud tank is an open-top container, typically made of square steel tube and steel plate, to store drilling fluid on a drilling rig. They are also called mud pits, as they were once simple pits in the earth.

A flow line, used on a drilling rig, is a large diameter pipe that is connected to the bell nipple and extends to the possum belly and acts as a return line, to the mud

Desanders and desilters are solid control equipment with a set of hydrocyclones that separate sand and silt from the drilling fluids in drilling rigs. Desanders are installed on top of the mud tank following the shale shaker and the degasser, but before the desilter. The desander removes the abrasive solids from the drilling fluids which cannot be removed by shakers. Normally, the solid diameters for desanders to separate would be 45~74μm, and 15~44μm for desilters.

In oil or gas well drilling, lost circulation occurs when drilling fluid, known commonly as "mud", flows into one or more geological formations instead of returning up the annulus. Lost circulation can be a serious problem during the drilling of an oil well or gas well.

Effective solids control can be attributed to the overall performance of all the components of the mud systems. Conditioning the drilling fluid with the goal of dramatically lowering maintenance cost, avoiding excessive chemical treatment and maintaining mud systems volume will decrease the chance of equipment failure, unnecessary high mud costs, hole and drilling problems.

Solids control is a process used in drilling rigs which use drilling fluid. It involves separating the "cuttings" from the fluid, allowing it to be recirculated or discharged to the environment.

Oil well control is the management of the dangerous effects caused by the unexpected release of formation fluid, such as natural gas and/or crude oil, upon surface equipment of oil or gas drilling rigs and escaping into the atmosphere. Technically, oil well control involves preventing the formation gas or fluid (hydrocarbons), usually referred to as kick, from entering into the wellbore during drilling or well interventions.

A service rig is a mobile platform loaded with oil industry service equipment that can be driven long distances within the oil fields to service wells. Unlike drilling rigs, service rigs return to a particular well many times.