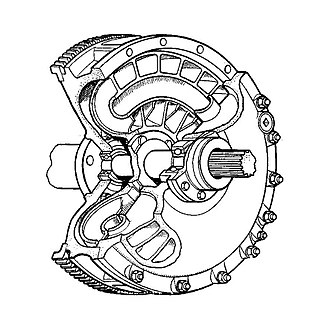

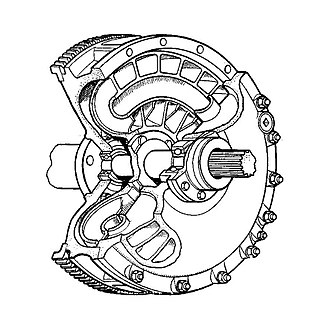

A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft to a driven shaft. In the simplest application, clutches connect and disconnect two rotating shafts. In these devices, one shaft is typically attached to an engine or other power unit, while the other shaft provides output power for work. Typically the motions involved are rotary, but linear clutches also exist.

A valve is a device or natural object that regulates, directs or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin valva, the moving part of a door, in turn from volvere, to turn, roll.

A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque-limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

An axle or axletree is a central shaft for a rotating wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to the vehicle, with the wheels rotating around the axle. In the former case, bearings or bushings are provided at the mounting points where the axle is supported. In the latter case, a bearing or bushing sits inside a central hole in the wheel to allow the wheel or gear to rotate around the axle. Sometimes, especially on bicycles, the latter type axle is referred to as a spindle.

A bicycle wheel is a wheel, most commonly a wire wheel, designed for a bicycle. A pair is often called a wheelset, especially in the context of ready built "off the shelf" performance-oriented wheels.

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly.

A continuously variable transmission (CVT) is an automatic transmission that can change seamlessly through a continuous range of gear ratios. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant RPM while the vehicle moves at varying speeds.

A limited-slip differential (LSD) is a type of differential that allows its two output shafts to rotate at different speeds but limits the maximum difference between the two shafts. Limited-slip differentials are often known by the generic trademark Positraction, a brand name owned by General Motors.

Constant-velocity joints are mechanical joints which allow a drive shaft to transmit power through a variable angle, at constant rotational speed, without an appreciable increase in friction or play. They are mainly used in front-wheel drive vehicles. Modern rear-wheel drive cars with independent rear suspension typically use CV joints at the ends of the rear axle halfshafts and increasingly use them on the drive shaft.

A drive shaft, driveshaft, driving shaft, tailshaft, propeller shaft, or Cardan shaft is a component for transmitting mechanical power and torque and rotation, usually used to connect other components of a drivetrain that cannot be connected directly because of distance or the need to allow for relative movement between them.

Torsional vibration is angular vibration of an object—commonly a shaft along its axis of rotation. Torsional vibration is often a concern in power transmission systems using rotating shafts or couplings where it can cause failures if not controlled. A second effect of torsional vibrations applies to passenger cars. Torsional vibrations can lead to seat vibrations or noise at certain speeds. Both reduce the comfort.

A belt is a loop of flexible material used to link two or more rotating shafts mechanically, most often parallel. Belts may be used as a source of motion, to transmit power efficiently or to track relative movement. Belts are looped over pulleys and may have a twist between the pulleys, and the shafts need not be parallel.

A fluid coupling or hydraulic coupling is a hydrodynamic or 'hydrokinetic' device used to transmit rotating mechanical power. It has been used in automobile transmissions as an alternative to a mechanical clutch. It also has widespread application in marine and industrial machine drives, where variable speed operation and controlled start-up without shock loading of the power transmission system is essential.

Splines are ridges or teeth on a drive shaft that matches with grooves in a mating piece and transfer torque to it, maintaining the angular correspondence between them.

Shaft alignment is the process of aligning two or more shafts with each other to within a tolerated margin. The resulting fault if alignment is not achieved within the demanded specifications is shaft misalignment, which may be offset or angular. Faults can lead to premature wear and damage to systems.

A jaw coupling is a type of general purpose power transmission coupling that also can be used in motion control (servo) applications. It is designed to transmit torque while damping system vibrations and accommodating misalignment, which protects other components from damage. Jaw couplings are composed of three parts: two metallic hubs and an elastomer insert called an element, but commonly referred to as a "spider". The three parts press fit together with a jaw from each hub fitted alternately with the lobes of the spider. Jaw coupling torque is transmitted through the elastomer lobes in compression.

A giubo, also known as a flex disc, and sometimes misspelled as guibo, is a flexible coupling used to transmit rotational torque between the drive shaft and the companion flange on mechanical devices, such as an automobile engine.

The Geislinger coupling is an all-metal coupling for rotating shafts. It is elastic in torsion, allowing it to absorb torsional vibration.

A Schmidt coupling is a type of coupling designed to accommodate large radial displacement between two shafts. Consisting of an arrangement of links and discs—three discs rotating in unison, interconnected in series by three or more links between each pair of disks—a Schmidt coupling can adapt to very wide variations in radial displacement while running under load. Couplings can be made to allow radial displacement greater than twice the radius of the disks.