Application

Dixon rings are used for mainly for laboratory distillation applications.

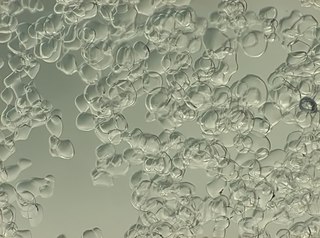

Dixon rings are a form of random packing used in chemical processing. They consist of a stainless steel mesh formed into a ring with a central divider, and are intended to be packed randomly into a packed column. Dixon rings provide a large surface area and low pressure drop while maintaining a high mass transfer rate, making them useful for distillations and many other applications.

Packed columns are used in a range of industries to allow intimate contact between two immiscible fluids which can be liquid/liquid or liquid/gas. The fluids are passed through in a countercurrent flow through a column.

Random column packing used to characterize the maximum volume fraction of a solid object obtained when they are packed randomly. This method of packing has been used since the early 1820s; the types of packing used were originally made out of glass spheres. However, in 1850 they were replaced by a more porous pumice stone and pieces of coke.

In the early 20th century Friedrich Raschig realized the importance of a high void fraction and having the internal surface of the packing media take part in the mass transfer. He designed the Raschig ring, which was more effective than previous forms of random packing and became very popular. Raschig rings are usually built from ceramic or metal and provided a large surface area within the column for interaction between liquid and gas vapors.

In 1943 Dr Olaf George Dixon of ICI applied for a patent of a new product for column distillation. [1] He used stainless steel mesh instead of sheet steel in the Lessing ring in order to improve the pressure drop of the packed column (in fact, they were called "wire gauze Lessing rings" in a 1949 publication [2] ).

High performance was achieved between radioactive and non-radioactive materials, [3] and despite high cost they are still used in the nuclear industry e. g. for water detritiation. [4]

Dixon rings are used for mainly for laboratory distillation applications.

The enhanced performance of the Dixon ring is based on liquid surface tension: when the mesh is wet its surface area increases greatly, with an accompanying increase in the rate of mass transfer. Dixon rings require pre-wetting (flow of liquid over the packed bed prior to starting the reaction flow). While this increases batch processing startup time, the increased performance of the Dixon ring overcomes this.

| Property | Ring size | ||

|---|---|---|---|

| 1⁄16" | 1⁄8" | 1⁄4" | |

| Surface area | 3550 | 2378 | 900 |

| Void space % | 94.63 | 90.98 | 90.73 |

| Number per litre | 102,000 | 24,400 | 2,965 |

Distillation, or classical distillation, is the process of separating the components or substances from a liquid mixture by using selective boiling and condensation, usually inside an apparatus known as a still. Dry distillation is the heating of solid materials to produce gaseous products ; this may involve chemical changes such as destructive distillation or cracking. Distillation may result in essentially complete separation, or it may be a partial separation that increases the concentration of selected components; in either case, the process exploits differences in the relative volatility of the mixture's components. In industrial applications, distillation is a unit operation of practically universal importance, but is a physical separation process, not a chemical reaction. An installation used for distillation, especially of distilled beverages, is a distillery. Distillation includes the following applications:

Mass transfer is the net movement of mass from one location to another. Mass transfer occurs in many processes, such as absorption, evaporation, drying, precipitation, membrane filtration, and distillation. Mass transfer is used by different scientific disciplines for different processes and mechanisms. The phrase is commonly used in engineering for physical processes that involve diffusive and convective transport of chemical species within physical systems.

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

Fractional distillation is the separation of a mixture into its component parts, or fractions. Chemical compounds are separated by heating them to a temperature at which one or more fractions of the mixture will vaporize. It uses distillation to fractionate. Generally the component parts have boiling points that differ by less than 25 °C (45 °F) from each other under a pressure of one atmosphere. If the difference in boiling points is greater than 25 °C, a simple distillation is typically used. It is used to refine crude oil.

Raschig rings are pieces of tube, approximately equal in length and diameter, used in large numbers as a packed bed within columns for distillations and other chemical engineering processes. They are usually ceramic, metal or glass and provide a large surface area within the volume of the column for interaction between liquid and gas vapours. Raschig rings are named after their inventor, German chemist Friedrich Raschig, who patented them in 1914.

A fractionating column or fractional column is an essential item used in the distillation of liquid mixtures to separate the mixture into its component parts, or fractions, based on the differences in volatilities. Fractionating columns are used in small-scale laboratory distillations as well as large-scale industrial distillations.

Vacuum distillation or Distillation under reduced pressure is a type of distillation performed under reduced pressure, which allows the purification of compounds not readily distilled at ambient pressures or simply to save time or energy. This technique separates compounds based on differences in their boiling points. This technique is used when the boiling point of the desired compound is difficult to achieve or will cause the compound to decompose. Reduced pressures decrease the boiling point of compounds. The reduction in boiling point can be calculated using a temperature-pressure nomograph using the Clausius–Clapeyron relation.

Column chromatography in chemistry is a chromatography method used to isolate a single chemical compound from a mixture. Chromatography is able to separate substances based on differential adsorption of compounds to the adsorbent; compounds move through the column at different rates, allowing them to be separated into fractions. The technique is widely applicable, as many different adsorbents can be used with a wide range of solvents. The technique can be used on scales from micrograms up to kilograms. The main advantage of column chromatography is the relatively low cost and disposability of the stationary phase used in the process. The latter prevents cross-contamination and stationary phase degradation due to recycling. Column chromatography can be done using gravity to move the solvent, or using compressed gas to push the solvent through the column.

Continuous distillation, a form of distillation, is an ongoing separation in which a mixture is continuously fed into the process and separated fractions are removed continuously as output streams. Distillation is the separation or partial separation of a liquid feed mixture into components or fractions by selective boiling and condensation. The process produces at least two output fractions. These fractions include at least one volatile distillate fraction, which has boiled and been separately captured as a vapor condensed to a liquid, and practically always a bottoms fraction, which is the least volatile residue that has not been separately captured as a condensed vapor.

In chemical processing, a packed bed is a hollow tube, pipe, or other vessel that is filled with a packing material. The packing can be randomly filled with small objects like Raschig rings or else it can be a specifically designed structured packing. Packed beds may also contain catalyst particles or adsorbents such as zeolite pellets, granular activated carbon, etc.

The term structured packing refers to a range of specially designed materials for use in absorption and distillation columns and chemical reactors. Structured packings typically consist of thin corrugated metal plates or gauzes arranged in a way that force fluids to take complicated paths through the column, thereby creating a large surface area for contact between different phases.

A zeotropicmixture, or non-azeotropic mixture, is a mixture with liquid components that have different boiling points. For example, nitrogen, methane, ethane, propane, and isobutane constitute a zeotropic mixture. Individual substances within the mixture do not evaporate or condense at the same temperature as one substance. In other words, the mixture has a temperature glide, as the phase change occurs in a temperature range of about four to seven degrees Celsius, rather than at a constant temperature. On temperature-composition graphs, this temperature glide can be seen as the temperature difference between the bubble point and dew point. For zeotropic mixtures, the temperatures on the bubble (boiling) curve are between the individual component's boiling temperatures. When a zeotropic mixture is boiled or condensed, the composition of the liquid and the vapor changes according to the mixtures's temperature-composition diagram.

Supercritical fluid chromatography (SFC) is a form of normal phase chromatography that uses a supercritical fluid such as carbon dioxide as the mobile phase. It is used for the analysis and purification of low to moderate molecular weight, thermally labile molecules and can also be used for the separation of chiral compounds. Principles are similar to those of high performance liquid chromatography (HPLC), however SFC typically utilizes carbon dioxide as the mobile phase; therefore the entire chromatographic flow path must be pressurized. Because the supercritical phase represents a state in which liquid and gas properties converge, supercritical fluid chromatography is sometimes called convergence chromatography.

A theoretical plate in many separation processes is a hypothetical zone or stage in which two phases, such as the liquid and vapor phases of a substance, establish an equilibrium with each other. Such equilibrium stages may also be referred to as an equilibrium stage, ideal stage, or a theoretical tray. The performance of many separation processes depends on having series of equilibrium stages and is enhanced by providing more such stages. In other words, having more theoretical plates increases the efficiency of the separation process be it either a distillation, absorption, chromatographic, adsorption or similar process.

Slurry ice is a phase changing refrigerant made up of millions of ice "micro-crystals" formed and suspended within a solution of water and a freezing point depressant. Some compounds used in the field are salt, ethylene glycol, propylene glycol, alcohols like isobutyl and ethanol, and sugars like sucrose and glucose. Slurry ice has greater heat absorption compared to single phase refrigerants like brine, because the melting enthalpy of the ice is also used.

In chemistry, a condenser is laboratory apparatus used to condense vapors – that is, turn them into liquids – by cooling them down.

Stripping is a physical separation process where one or more components are removed from a liquid stream by a vapor stream. In industrial applications the liquid and vapor streams can have co-current or countercurrent flows. Stripping is usually carried out in either a packed or trayed column.

Catalytic distillation is a branch of reactive distillation which combines the processes of distillation and catalysis to selectively separate mixtures within solutions. Its main function is to maximize the yield of catalytic organic reactions, such as the refining of gasoline. The earliest case of catalytic distillation was thought to have dated back to 1966; however, the idea was officially patented in 1980 by Lawrence A. Smith, Jr. The process is currently used to purify gasoline, extract rubber, and form plastics.

Capillary electrochromatography (CEC) is a chromatographic technique in which the mobile phase is driven through the chromatographic bed by electroosmosis. Capillary electrochromatography is a combination of two analytical techniques, high-performance liquid chromatography and capillary electrophoresis. Capillary electrophoresis aims to separate analytes on the basis of their mass-to-charge ratio by passing a high voltage across ends of a capillary tube, which is filled with the analyte. High-performance liquid chromatography separates analytes by passing them, under high pressure, through a column filled with stationary phase. The interactions between the analytes and the stationary phase and mobile phase lead to the separation of the analytes. In capillary electrochromatography capillaries, packed with HPLC stationary phase, are subjected to a high voltage. Separation is achieved by electrophoretic migration of solutes and differential partitioning.

Random column packing is the practice of packing a distillation column with randomly fitting filtration material in order to optimize surface area over which reactants can interact while minimizing the complexity of construction of such columns. Random column packing is an alternative to structured column packing.