A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft to a driven shaft. In the simplest application, clutches connect and disconnect two rotating shafts. In these devices, one shaft is typically attached to an engine or other power unit, while the other shaft provides output power for work. Typically the motions involved are rotary, but linear clutches also exist.

Heel-and-toe shifting is an advanced driving technique used mostly in performance driving with a manual gearbox, although some drivers use it on the road in everyday conditions in the interest of effectiveness. It involves operating the throttle and brake pedals simultaneously with the right foot, while facilitating normal activation of the clutch with the left foot. It is used when braking and downshifting simultaneously, and allows the driver to "blip" the throttle to raise the engine speed and smoothly engage the lower gear.

An automatic transmission is a multi-speed transmission used in internal combustion engine-based motor vehicles that does not require any driver input to change forward gears under normal driving conditions. It typically includes a transmission, axle, and differential in one integrated assembly, thus technically becoming a transaxle.

Overdrive is the operation of an automobile cruising at sustained speed with reduced engine revolutions per minute (RPM), leading to better fuel consumption, lower noise, and lower wear. The term is ambiguous. The most fundamental meaning is that of an overall gear ratio between engine and wheels, such that the car is over-geared, and cannot reach its potential top speed, i.e. the car could travel faster if it were in a lower gear, with the engine turning at higher RPM.

Propulsion transmission is the mode of transmitting and controlling propulsion power of a machine. The term transmission properly refers to the whole drivetrain, including clutch, gearbox, prop shaft, differential, and final drive shafts. In the United States the term is sometimes used in casual speech to refer more specifically to the gearbox alone, and detailed usage differs. The transmission reduces the higher engine speed to the slower wheel speed, increasing torque in the process. Transmissions are also used on pedal bicycles, fixed machines, and where different rotational speeds and torques are adapted.

A manual transmission (MT), also known as manual gearbox, standard transmission, or stick shift, is a multi-speed motor vehicle transmission system, where gear changes require the driver to manually select the gears by operating a gear stick and clutch.

In mechanical or automotive engineering, a freewheel or overrunning clutch is a device in a transmission that disengages the driveshaft from the driven shaft when the driven shaft rotates faster than the driveshaft. An overdrive is sometimes mistakenly called a freewheel, but is otherwise unrelated.

Engine braking occurs when the retarding forces within an engine are used to slow down a motor vehicle, as opposed to using additional external braking mechanisms such as friction brakes or magnetic brakes.

Hydramatic is an automatic transmission developed by both General Motors' Cadillac and Oldsmobile divisions. Introduced in 1939 for the 1940 model year vehicles, the Hydramatic was the first mass-produced fully-automatic transmission developed for passenger automobile use.

A direct-shift gearbox is an electronically-controlled, dual-clutch, multiple-shaft, automatic gearbox, in either a transaxle or traditional transmission layout, with automated clutch operation, and with fully-automatic or semi-manual gear selection. The first dual-clutch transmissions were derived from Porsche in-house development for the Porsche 962 in the 1980s.

A preselector gearbox is a type of manual transmission mostly used on passenger cars and racing cars in the 1930s, in buses from 1940-1960 and in armoured vehicles from the 1930s to the 1970s. The defining characteristic of a preselector gearbox is that the gear shift lever allowed the driver to "pre-select" the next gear, usually with the transmission remaining in the current gear until the driver pressed the "gear change pedal" at the desired time.

The automated manual transmission (AMT) is a type of transmission for motor vehicles. It is essentially a conventional manual transmission but uses automatic actuation to operate the clutch and/or shift between gears.

A transmission control unit (TCU), also known as a transmission control module (TCM), or a gearbox control unit (GCU), is a type of automotive ECU that is used to control electronic automatic transmissions. Similar systems are used in conjunction with various semi-automatic transmissions, purely for clutch automation and actuation. A TCU in a modern automatic transmission generally uses sensors from the vehicle, as well as data provided by the engine control unit (ECU), to calculate how and when to change gears in the vehicle for optimum performance, fuel economy and shift quality.

Clutch control refers to the act of controlling the speed of a vehicle with a manual transmission by partially engaging the clutch plate, using the clutch pedal instead of the accelerator pedal. The purpose of a clutch is in part to allow such control; in particular, a clutch provides transfer of torque between shafts spinning at different speeds. In the extreme, clutch control is used in performance driving, such as starting from a dead stop with the engine producing maximum torque at high RPM.

Chevrolet Corvair Powerglide is a two-speed automatic transmission designed specially for the then all-new 1960 Chevrolet Corvair compact car that emerged in the fall of 1959 as Chevrolet's competitor in the then booming small car market. The Corvair was powered by a rear-mounted Chevrolet Turbo-Air 6 engine that necessitated a specially designed transaxle. Corvair Powerglide took the principles of the standard Chevrolet Powerglide and modified them to suit the rear-mounted powertrain location of the new Corvair. The Corvair used the Powerglide for all 10 years it was produced; from 1961 to 1963, Pontiac used a modified version of Corvair Powerglide it called 'TempesTorque' for its front-engine, rear-transaxle Tempest, LeMans and Tempest LeMans cars.

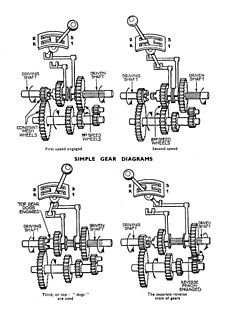

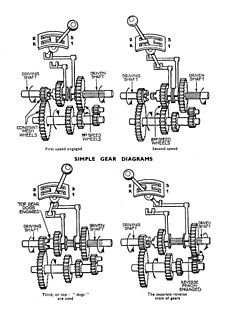

A non-synchronous transmission, also called a crash gearbox, is a form of manual transmission based on gears that do not use synchronizing mechanisms. They require the driver to manually synchronize the transmission's input speed and output speed.

Synchronized downshift rev-matching system is a technology invented by Nissan for use on the Nissan 370Z. In combination with the Engine Control Unit (ECU) and various sensors, the engine electronically blips the throttle for the driver during both downshifts and upshifts to allow for better and smoother shifting, and improved handling.

A motorcycle transmission is a transmission created specifically for motorcycle applications. They may also be found in use on other light vehicles such as motor tricycles and quadbikes, go-karts, offroad buggies, auto rickshaws, mowers, and other utility vehicles, microcars, and even some superlight racing cars.

The Voith DIWA automotive transmission was designed by Voith primarily for city-buses and suburban buses. The transmission utilizes a Differential-Wandler (Converter) or DIWA which replaces two gears which would be used on a conventional transmission. Voith has designed many variations and generations of the Voith DIWA.

Car controls are the components in automobiles and other powered road vehicles, such as trucks and buses, used for driving and parking.