Hygroscopy is the phenomenon of attracting and holding water molecules via either absorption or adsorption from the surrounding environment, which is usually at normal or room temperature. If water molecules become suspended among the substance's molecules, adsorbing substances can become physically changed, e.g. changing in volume, boiling point, viscosity or some other physical characteristic or property of the substance. For example, a finely dispersed hygroscopic powder, such as a salt, may become clumpy over time due to collection of moisture from the surrounding environment.

A dehumidifier is an air conditioning device which reduces and maintains the level of humidity in the air. This is done usually for health or thermal comfort reasons, or to eliminate musty odor and to prevent the growth of mildew by extracting water from the air. It can be used for household, commercial, or industrial applications. Large dehumidifiers are used in commercial buildings such as indoor ice rinks and swimming pools, as well as manufacturing plants or storage warehouses. Typical air conditioning systems combine dehumidification with cooling, by operating cooling coils below the dewpoint and draining away the water that condenses.

A hygrometer is an instrument which measures the humidity of air or some other gas: that is, how much water vapor it contains. Humidity measurement instruments usually rely on measurements of some other quantities such as temperature, pressure, mass and mechanical or electrical changes in a substance as moisture is absorbed. By calibration and calculation, these measured quantities can lead to a measurement of humidity. Modern electronic devices use the temperature of condensation, or they sense changes in electrical capacitance or resistance to measure humidity differences. A crude hygrometer was invented by Leonardo da Vinci in 1480. Major leaps came forward during the 1600s; Francesco Folli invented a more practical version of the device, while Robert Hooke improved a number of meteorological devices including the hygrometer. A more modern version was created by Swiss polymath Johann Heinrich Lambert in 1755. Later, in the year 1783, Swiss physicist and Geologist Horace Bénédict de Saussure invented the first hygrometer using human hair to measure humidity.

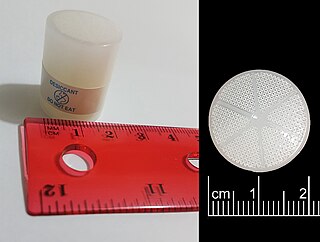

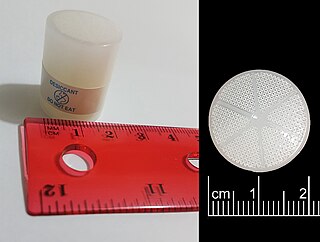

A desiccant is a hygroscopic substance that is used to induce or sustain a state of dryness (desiccation) in its vicinity; it is the opposite of a humectant. Commonly encountered pre-packaged desiccants are solids that absorb water. Desiccants for specialized purposes may be in forms other than solid, and may work through other principles, such as chemical bonding of water molecules. They are commonly encountered in foods to retain crispness. Industrially, desiccants are widely used to control the level of water in gas streams.

A humidor is a humidity-controlled box or room used primarily for storing cigars, cigarettes, cannabis, or pipe tobacco. Either too much or too little humidity can be harmful to tobacco products; a humidor's primary function is to maintain a steady, desirable moisture level inside; secondarily it protects its contents from physical damage and deterioration from sunlight. For private use, small wooden boxes holding a few dozen or fewer cigars are common, while cigar shops may have walk-in humidors. Many humidors use hygrometers to monitor their humidity levels. When used and maintained properly, humidors can keep cigars fresh and in perfect condition for up to five years.

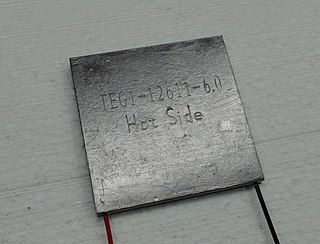

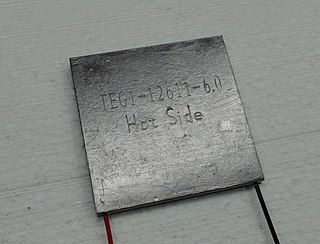

Thermoelectric cooling uses the Peltier effect to create a heat flux at the junction of two different types of materials. A Peltier cooler, heater, or thermoelectric heat pump is a solid-state active heat pump which transfers heat from one side of the device to the other, with consumption of electrical energy, depending on the direction of the current. Such an instrument is also called a Peltier device, Peltier heat pump, solid state refrigerator, or thermoelectric cooler (TEC) and occasionally a thermoelectric battery. It can be used either for heating or for cooling, although in practice the main application is cooling. It can also be used as a temperature controller that either heats or cools.

A diving air compressor is a breathing air compressor that can provide breathing air directly to a surface-supplied diver, or fill diving cylinders with high-pressure air pure enough to be used as a hyperbaric breathing gas. A low pressure diving air compressor usually has a delivery pressure of up to 30 bar, which is regulated to suit the depth of the dive. A high pressure diving compressor has a delivery pressure which is usually over 150 bar, and is commonly between 200 and 300 bar. The pressure is limited by an overpressure valve which may be adjustable.

Desiccators are sealable enclosures containing desiccants used for preserving moisture-sensitive items such as cobalt chloride paper for another use. A common use for desiccators is to protect chemicals which are hygroscopic or which react with water from humidity.

An evaporative cooler is a device that cools air through the evaporation of water. Evaporative cooling differs from other air conditioning systems, which use vapor-compression or absorption refrigeration cycles. Evaporative cooling exploits the fact that water will absorb a relatively large amount of heat in order to evaporate. The temperature of dry air can be dropped significantly through the phase transition of liquid water to water vapor (evaporation). This can cool air using much less energy than refrigeration. In extremely dry climates, evaporative cooling of air has the added benefit of conditioning the air with more moisture for the comfort of building occupants.

A humidifier is a household appliance or device designed to increase the moisture level in the air within a room or an enclosed space. It achieves this by emitting water droplets or steam into the surrounding air, thereby raising the humidity.

Moisture sensitivity level (MSL) is a rating that shows a device's susceptibility to damage due to absorbed moisture when subjected to reflow soldering as defined in J-STD-020. It relates to the packaging and handling precautions for some semiconductors. The MSL is an electronic standard for the time period in which a moisture sensitive device can be exposed to ambient room conditions.

A humidity indicator card (HIC) is a card on which a moisture-sensitive chemical is impregnated such that it will change color when the indicated relative humidity (RH) is exceeded. This has usually been a blotting paper impregnated with cobalt(II) chloride base; Less toxic alternatives include other chemicals such as cobalt-free chloride base and special plastic films.

A pot-in-pot refrigerator, clay pot cooler or zeer is an evaporative cooling refrigeration device which does not use electricity. It uses a porous outer clay pot containing an inner pot within which the food is placed. The evaporation of the outer liquid draws heat from the inner pot. The device can cool any substance, and requires only a flow of relatively dry air and a source of water.

An atmospheric water generator (AWG), is a device that extracts water from humid ambient air, producing potable water. Water vapor in the air can be extracted either by condensation - cooling the air below its dew point, exposing the air to desiccants, using membranes that only pass water vapor, collecting fog, or pressurizing the air. AWGs are useful where potable water is difficult to obtain, because water is always present in ambient air.

Solar air conditioning, or "solar-powered air conditioning", refers to any air conditioning (cooling) system that uses solar power.

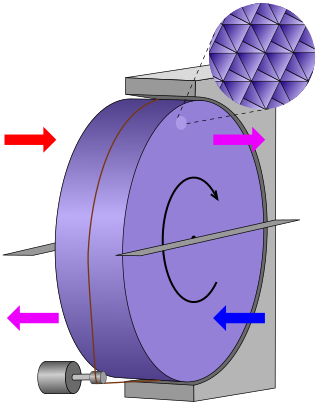

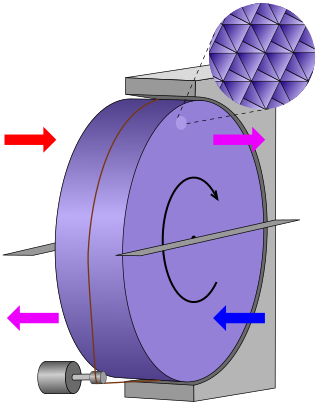

A thermal wheel, also known as a rotary heat exchanger, or rotary air-to-air enthalpy wheel, energy recovery wheel, or heat recovery wheel, is a type of energy recovery heat exchanger positioned within the supply and exhaust air streams of air-handling units or rooftop units or in the exhaust gases of an industrial process, in order to recover the heat energy. Other variants include enthalpy wheels and desiccant wheels. A cooling-specific thermal wheel is sometimes referred to as a Kyoto wheel.

The sweet potato is a very important crop for subsistence farmers in Africa and developing countries in other regions. Its relatively short growing period, tolerance to drought and high yield from poor soils lead to its use as a famine reserve for many of these households. However, it is a highly perishable food source that is susceptible to destruction by microorganisms, metabolic spoilage, physical destruction and pests. Therefore, it is not generally stored for long after harvest. This is a major barrier for the optimal use of the crop and causes much waste.

Grain drying is process of drying grain to prevent spoilage during storage. The grain drying described in this article is that which uses fuel- or electric-powered processes supplementary to natural ones, including swathing/windrowing for drying by ambient air and sunshine, or stooking before threshing.

Compressed air dryers are special types of filter systems that are specifically designed to remove the water that is inherent in compressed air. The compression of air raises its temperature and concentrates atmospheric contaminants, primarily water vapor, as resulting in air with elevated temperature and 100% relative humidity. As the compressed air cools down, water vapor condenses into the tank(s), pipes, hoses and tools connected downstream from the compressor which may be damaging. Therefore water vapor is removed from compressed air to prevent condensation from occurring and to prevent moisture from interfering in sensitive industrial processes.

The Cromer cycle is a thermodynamic cycle that uses a desiccant to interact with higher relative humidity air leaving a cold surface. When a system is taken through a series of different states and finally returned to its initial state, a thermodynamic cycle is said to have occurred. The desiccant absorbs moisture from the air leaving the cold surface, releasing heat and drying the air, which can be used in a process requiring dry air. The desiccant is then dried by an air stream at a lower relative humidity, where the desiccant gives up its moisture by evaporation, increasing the air's relative humidity and cooling it. This cooler, moister air can then be presented to the same cold surface as above to take it below its dew point and dry it further, or it can be expunged from the system.