Related Research Articles

Steel is an alloy made up of iron with typically a few tenths of a percent of carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant need typically an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, and weapons. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms : body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties.

Vulcan Iron Works was the name of several iron foundries in both England and the United States during the Industrial Revolution and, in one case, lasting until the mid-20th century. Vulcan, the Roman god of fire and smithery, was a popular namesake for these foundries.

A steel mill or steelworks is an industrial plant for the manufacture of steel. It may be an integrated steel works carrying out all steps of steelmaking from smelting iron ore to rolled product, but may also be a plant where steel semi-finished casting products are made from molten pig iron or from scrap.

A reverberatory furnace is a metallurgical or process furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term reverberation is used here in a generic sense of rebounding or reflecting, not in the acoustic sense of echoing.

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals processed are aluminum and cast iron. However, other metals, such as bronze, brass, steel, magnesium, and zinc, are also used to produce castings in foundries. In this process, parts of desired shapes and sizes can be formed.

An induction furnace is an electrical furnace in which the heat is applied by induction heating of metal. Induction furnace capacities range from less than one kilogram to one hundred tons, and are used to melt iron and steel, copper, aluminum, and precious metals.

Bellfounding is the casting and tuning of large bronze bells in a foundry for use in such as churches, clock towers and public buildings, either to signify the time or an event, or as a musical carillon or chime. Large bells are made by casting bell metal in moulds designed for their intended musical pitches. Further fine tuning is then performed using a lathe to shave metal from the bell to produce a distinctive bell tone by sounding the correct musical harmonics.

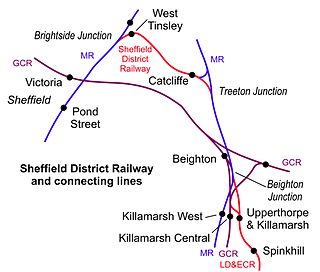

West Tinsley railway station is a former railway station in Sheffield, South Yorkshire, England.

In metallurgy, a ladle is a vessel used to transport and pour out molten metals. Ladles are often used in foundries and range in size from small hand carried vessels that resemble a kitchen ladle and hold 20 kilograms (44 lb) to large steelmill ladles that hold up to 300 tonnes. Many non-ferrous foundries also use ceramic crucibles for transporting and pouring molten metal and will also refer to these as ladles.

Newton, Chambers & Co. was one of England's largest industrial companies. It was founded in 1789 by George Newton and Thomas Chambers.

Samuel Osborn and Company was a steelmaker and engineering tool manufacturer situated in Sheffield, South Yorkshire.

Steel, Peech and Tozer was a large steel maker with works situated at Ickles and Templeborough, in Rotherham, South Yorkshire, England.

Brown Bayley Steels was a steel-making company established in Sheffield, England in 1871, as Brown, Bayley & Dixon. They occupied a site on Leeds Road which was later occupied by the Don Valley sports stadium. The firm was founded by George Brown, Nephew of "John Brown" of the firm John Brown & Company. The firm manufactured Bessemer steel and railway tracks.

Hadfields Limited of Hecla and East Hecla Sheffield, Yorkshire was a British manufacturer of special steels in particular manganese alloys and the manufacture of steel castings.

Jessop Saville and Company, the Sheffield-based special steel makers, was founded in 1929 following a merger of J.J.Saville and Co., Limited and William Jessop and Company, both of these being long established in the trade and in the city.

Markham & Co. was an ironworks and steelworks company near Chesterfield, Derbyshire, England.

Mangalloy, also called manganese steel or Hadfield steel, is an alloy steel containing an average of around 13% manganese. Mangalloy is known for its high impact strength and resistance to abrasion once in its work-hardened state.

Electrotherm (India) Limited was founded in 1983 to cater to the needs of all segments of steel industry, foundries and heat treatment industry. Today, Electrotherm is a diversified conglomerate having businesses in the field of Engineering & Projects catering to steel and foundry industry; transformer manufacturing; steel making; ductile iron pipe making; manufacturing of battery operated vehicles; renewable energy; transmission line tower and education.

The Panteg Steel Works was situated in the village of Panteg, adjacent to Sebastopol, and Griffithstown, in the district of Torfaen, South Wales. The steel works was founded in 1873, and operated for over 130 years until its closure in 2004. A number of 'firsts' occurred at Panteg Steel Works during its long life, including the first full production of stainless steel in the UK outside Sheffield in 1944, the installation of the first production vertical caster in the UK in 1960 and the commissioning of British Steel's first Argon Oxygen Decarburizer in 1972. Planning permission was given to turn the works into residential housing in 2010, when the site became the Parc Panteg housing estate.

Braithwaite & Co. Limited is a manufacturing company which is fully owned by Government of India having its headquarters at Kolkata, West Bengal. The company has three units – Clive Works, Victoria Works both in Calcutta and Angus Works in Hooghly District, West Bengal. From 2010 the administrative control of the company has been taken over by the Ministry of Railways.

References

- Internal company magazine Edgar Allen News.

- Internal documentation relating to the 1960s rationalisation.