Related Research Articles

Collinsville is a village and census-designated place (CDP) in the town of Canton, Hartford County, Connecticut, United States. The population was 3,746 at the 2010 census. The central portion of the village is a historic district listed on the National Register of Historic Places.

Samuel Colt was an American inventor, industrialist, and businessman who established Colt's Patent Fire-Arms Manufacturing Company and made the mass production of revolvers commercially viable.

The American system of manufacturing was a set of manufacturing methods that evolved in the 19th century. The two notable features were the extensive use of interchangeable parts and mechanization for production, which resulted in more efficient use of labor compared to hand methods. The system was also known as armory practice because it was first fully developed in armories, namely, the United States Armories at Springfield in Massachusetts and Harpers Ferry in Virginia, inside contractors to supply the United States Armed Forces, and various private armories. The name "American system" came not from any aspect of the system that is unique to the American national character, but simply from the fact that for a time in the 19th century it was strongly associated with the American companies who first successfully implemented it, and how their methods contrasted with those of British and continental European companies. In the 1850s, the "American system" was contrasted to the British factory system which had evolved over the previous century. Within a few decades, manufacturing technology had evolved further, and the ideas behind the "American" system were in use worldwide. Therefore, in manufacturing today, which is global in the scope of its methods, there is no longer any such distinction.

Colt's Manufacturing Company, LLC is an American firearms manufacturer, founded in 1855 by Samuel Colt and is now a subsidiary of Czech holding company Colt CZ Group. It is the successor corporation to Colt's earlier firearms-making efforts, which started in 1836. Colt is known for the engineering, production, and marketing of firearms, most especially between the 1850s and World War I, when it was a dominating force in its industry and a seminal influence on manufacturing technology. Colt's earliest designs played a major role in the popularization of the revolver and the shift away from earlier single-shot pistols. Although Samuel Colt did not invent the revolver concept, his designs resulted in the first very successful ones.

Elisha Haydon Collier (1788–1856) of Boston, USA, invented a flintlock revolver around 1814. His weapon is one of the earliest true revolvers, in contrast to the earlier pepperboxes which were multi-barreled guns. Collier's revolver was not self rotating but it was self-priming: a compartment automatically released gunpowder into the pan when the hammer was cocked.

Interchangeable parts are parts that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into any assembly of the same type. One such part can freely replace another, without any custom fitting, such as filing. This interchangeability allows easy assembly of new devices, and easier repair of existing devices, while minimizing both the time and skill required of the person doing the assembly or repair.

Francis Ashbury Pratt was an American mechanical engineer, inventor, and co-founder of Pratt & Whitney.

Simeon North was a Middletown, Connecticut, gun manufacturer, who developed one of America's first milling machines in 1818 and played an important role in the development of interchangeable parts manufacturing.

Charles Ethan Billings (1834–1920) was an American mechanical engineer, inventor, superintendent, and businessman. He held various U.S. patents on hand tools, either assigned or licensed to the firm that he and Christopher M. Spencer cofounded, the Billings & Spencer Company. His name as patent holder is stamped on countless forged hand tools, many of which survive. Billings was an expert in drop forging and was an influential leader in the American system of manufacturing and its successor systems of mass production for firearms, sewing machines, hand tools, bicycles, and other goods. He served as president of the American Society of Mechanical Engineers in 1895 and 1896. The Billings & Spencer Company was both a machine tool builder and a manufacturer of hand tools made with its machine tools.

Eli Terry Sr. was an inventor and clockmaker in Connecticut. He received a United States patent for a shelf clock mechanism. He introduced mass production to the art of clockmaking, which made clocks affordable for the average American citizen. Terry occupies an important place in the beginnings of the development of interchangeable parts manufacturing. Terry is considered the first person in American history to actually accomplish interchangeable parts with no government funding. Terry became one of the most accomplished mechanics in New England during the early part of the nineteenth century. The village of Terryville, Connecticut is named for his son, Eli Terry Jr.

The history of Connecticut Industry is a major part of the history of Connecticut. Between the birth of the U.S. patent system in 1790 and 1930, Connecticut had more patents issued per capita than any other state; in the 19th century, when the U.S. as a whole was issued one patent per three thousand population, Connecticut inventors were issued one patent for every 700–1000 residents. Connecticut's first recorded invention was a lapidary machine, by Abel Buell of Killingworth, in 1765.

The Colt Armory is a historic factory complex for the manufacture of firearms, created by Samuel Colt. It is located in Hartford, Connecticut along the Connecticut River, and as of 2008 is part of the Coltsville Historic District, named a National Historic Landmark District. It is slated to become part of Coltsville National Historical Park, now undergoing planning by the National Park Service.

The Colt Paterson revolver was the first commercial repeating firearm employing a revolving cylinder with multiple chambers aligned with a single, stationary barrel. Its design was patented by Samuel Colt on February 25, 1836, in the United States, England and France, and it derived its name from being produced in Paterson, New Jersey. Initially this 5 shot revolver was produced in .28 caliber, with a .36 caliber model following a year later. As originally designed and produced, no loading lever was included with the revolver; a user had to partially disassemble the revolver to re-load it. Starting in 1839, however, a reloading lever and a capping window were incorporated into the design, allowing reloading without disassembly. This loading lever and capping window design change was also incorporated after the fact into most Colt Paterson revolvers that had been produced from 1836 until 1839. Unlike later revolvers, a folding trigger was incorporated into the Colt Paterson. The trigger became visible only upon cocking the hammer.

Bullough's Pond, a former mill pond located in Newton, Massachusetts, is now a decorative pond in a suburban neighborhood, used for bird watching and walking. In the nineteenth century it was the site of a commercial ice business. Since the early 2000s, temperatures have warmed to the point that its winter ice is no longer thick enough to support skating safely.

Diana Muir, also known as Diana Muir Appelbaum, is a Newton, Massachusetts, USA, historian best known for her 2000 book Reflections in Bullough's Pond, a history of the impact of human activity on the New England ecosystem.

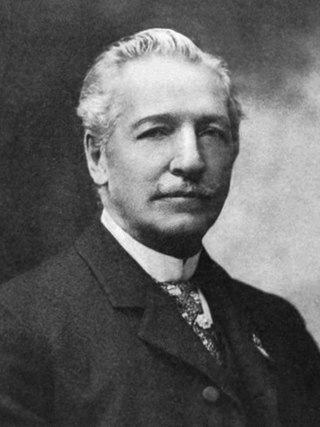

Samuel Watkinson Collins (1802–1870) was an American businessman and founder of the Collins Axe Company in Canton, Connecticut.

Reflections in Bullough's Pond: Economy and Ecosystem in New England is a book by Diana Muir. The Providence Journal called Bullough’s Pond "a masterpiece," and Publishers Weekly called it "lyrical". The Massachusetts Center for the Book awarded the 2001 Massachusetts Book Award to Bullough's Pond for the author’s "engaging and accomplished storytelling."

Christopher Miner Spencer was an American inventor, from Manchester, Connecticut, who invented the Spencer repeating rifle, one of the earliest models of lever-action rifle, a steam powered "horseless carriage", and several other inventions. He developed the first fully automatic turret lathe, which in its small- to medium-sized form is also known as a screw machine.

Coltsville Historic District is a National Historic Landmark District in Hartford, Connecticut. The district encompasses the factory, worker housing, and owner residences associated with Samuel Colt (1814-1862), one of the nation's early innovators in precision manufacturing and the production of firearms. It was the site of important contributions to manufacturing technology made by Colt and the industrial enterprise he created. Coltsville is a cohesive and readily identifiable 260-acre (110 ha) area, part of which was originally listed as the Colt Industrial District on the National Register of Historic Places in 1976. It was designated a National Historic Landmark in 2008.

Elizabeth Jarvis Colt was the widow and heir of firearms manufacturer Samuel Colt, founder of Colt's Manufacturing Company.

References

- ↑ Barnard, Henry (1866). Armsmear: The Home, the Arm, and the Armory of Samuel Colt. A Memorial. Mit Abbildungen. pp. 259–261.

- ↑ Muir 2000.

- ↑ Muir 2000 , p. 131.

- ↑ Roe 1916, pp. 168–170.

- ↑ Root Genealogical Records. 1600-1870