Enterprise resource planning (ERP) is the integrated management of main business processes, often in real-time and mediated by software and technology. ERP is usually referred to as a category of business management software—typically a suite of integrated applications—that an organization can use to collect, store, manage and interpret data from many business activities. ERP systems can be local-based or cloud-based. Cloud-based applications have grown in recent years due to the increased efficiencies arising from information being readily available from any location with Internet access.

A distributed control system (DCS) is a computerised control system for a process or plant usually with many control loops, in which autonomous controllers are distributed throughout the system, but there is no central operator supervisory control. This is in contrast to systems that use centralized controllers; either discrete controllers located at a central control room or within a central computer. The DCS concept increases reliability and reduces installation costs by localising control functions near the process plant, with remote monitoring and supervision.

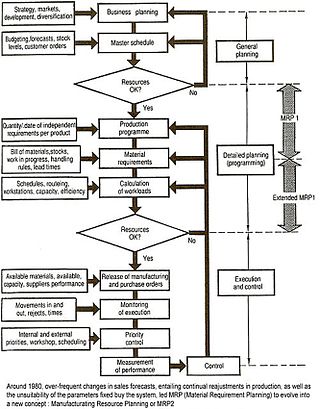

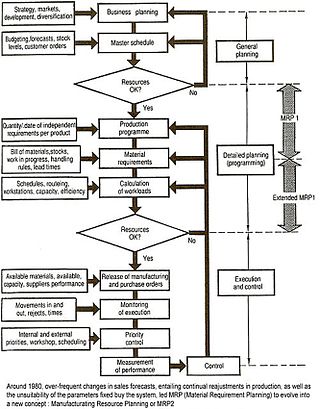

Manufacturingresource planning is a method for the effective planning of all resources of a manufacturing company. Ideally, it addresses operational planning in units, financial planning, and has a simulation capability to answer "what-if" questions and is an extension of closed-loop MRP.

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process. This integration allows individual processes to exchange information with each part. Manufacturing can be faster and less error-prone by the integration of computers. Typically CIM relies on closed-loop control processes based on real-time input from sensors. It is also known as flexible design and manufacturing.

Enterprise software, also known as enterprise application software (EAS), is computer software used to satisfy the needs of an organization rather than individual users. Such organizations include businesses, schools, interest-based user groups, clubs, charities, and governments. Enterprise software is an integral part of a computer-based information system.

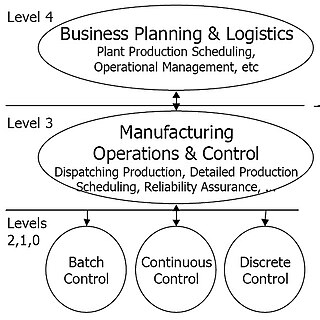

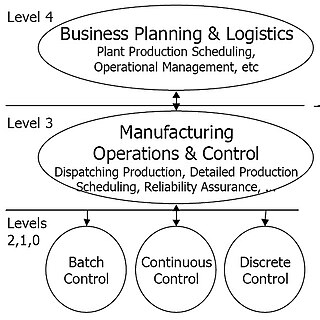

ANSI/ISA-95, or ISA-95 as it is more commonly referred, is an international standard from the International Society of Automation for developing an automated interface between enterprise and control systems. This standard has been developed for global manufacturers. It was developed to be applied in all industries, and in all sorts of processes, like batch processes, continuous and repetitive processes.

OpenO&M is an initiative of the following industry standards organisations:

IEC 62264 is an international standard for enterprise control system integration. This standard is based upon ANSI/ISA-95.

Manufacturing operations management (MOM) is a collection of systems for managing end-to-end manufacturing processes with a view to optimizing efficiency.

STEP-NC is a machine tool control language that extends the ISO 10303 STEP standards with the machining model in ISO 14649, adding geometric dimension and tolerance data for inspection, and the STEP PDM model for integration into the wider enterprise. The combined result has been standardized as ISO 10303-238.

Manufacturing execution systems (MES) are computerized systems used in manufacturing to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision-makers understand how current conditions on the plant floor can be optimized to improve production output. MES works as real-time monitoring system to enable the control of multiple elements of the production process.

An enterprise appliance transaction module (EATM) is a device, typically used in the manufacturing automation marketplace, for the transfer of plant floor equipment and product status to manufacturing execution systems (MES), enterprise resource planning (ERP) systems and the like.

PackML is an industry technical standard for the control of packaging machines, as an aspect of industrial automation.

brewmaxx is a process control system for the brewing industry. The various process steps of a brewery can be automated, controlled and monitored via the software components of the brewmaxx range.

Maverick Technologies is an industrial automation, enterprise integration, operational consulting and sustaining services provider. The company has over 500 employees and 18 U.S. locations and operations worldwide and is the largest independent systems integrator in North America.

Siemens Digital Industries Software is an American computer software company specializing in 3D & 2D Product Lifecycle Management (PLM) software. The company is a business unit of Siemens, operates under the legal name of Siemens Industry Software Inc, and is headquartered in Plano, Texas.

Manufacturing Enterprise Solutions Association International is a worldwide not-for-profit community of manufacturing companies, information technology hardware and software suppliers, system integrators, consulting service providers, analysts, editors, academics, and students. MESA's goal is to help member companies improve business results and production operations through application and implementation of information technology and best management practices.

Purdue Enterprise Reference Architecture (PERA), or the Purdue model, is a 1990s reference model for enterprise architecture, developed by Theodore J. Williams and members of the Industry-Purdue University Consortium for Computer Integrated Manufacturing.

Theodore Joseph Williams was an American engineer and Professor of Engineering at Purdue University, known for the development of the Purdue Enterprise Reference Architecture.

Warehouse execution systems (WES) are computerized systems used in warehouses and distribution centers to manage and orchestrate the physical flow of products from receiving through shipping. Warehouses are storage facilities for raw materials and parts used in manufacturing operations; distribution centers (DCs) are facilities that store and distribute finished goods to retail locations, consumers, and other end customers.