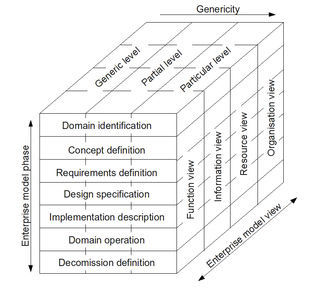

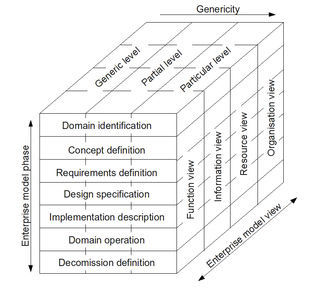

CIMOSA, standing for "Computer Integrated Manufacturing Open System Architecture", is an enterprise modeling framework, which aims to support the enterprise integration of machines, computers and people. The framework is based on the system life cycle concept, and offers a modelling language, methodology and supporting technology to support these goals.

Enterprise integration is a technical field of enterprise architecture, which is focused on the study of topics such as system interconnection, electronic data interchange, product data exchange and distributed computing environments.

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process. This integration allows individual processes to exchange information with each part. Manufacturing can be faster and less error-prone by the integration of computers. Typically CIM relies on closed-loop control processes based on real-time input from sensors. It is also known as flexible design and manufacturing.

Enterprise modelling is the abstract representation, description and definition of the structure, processes, information and resources of an identifiable business, government body, or other large organization.

Manufacturing execution systems (MES) are computerized systems used in manufacturing to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision-makers understand how current conditions on the plant floor can be optimized to improve production output. MES works as real-time monitoring system to enable the control of multiple elements of the production process.

Enterprise life cycle (ELC) in enterprise architecture is the dynamic, iterative process of changing the enterprise over time by incorporating new business processes, new technology, and new capabilities, as well as maintenance, disposition and disposal of existing elements of the enterprise.

Generalised Enterprise Reference Architecture and Methodology (GERAM) is a generalised enterprise architecture framework for enterprise integration and business process engineering. It identifies the set of components recommended for use in enterprise engineering.

François B. Vernadat is a French and Canadian computer scientist, who has contributed to Enterprise Modelling, Enterprise Integration and Networking over the last 40 years specialising in Enterprise Architectures, business process modelling, information systems design and analysis, systems integration and interoperability and systems analysis using Petri nets.

Peter Bernus is a Hungarian Australian scientist and Associate Professor of Enterprise Architecture at the School of Information and Communication Technology, Griffith University, Brisbane, Australia.

James G. "Jim" Nell is an American engineer. He was the principal investigator of the Manufacturing Enterprise Integration Project at the National Institute of Standards and Technology (NIST), and is known for his work on enterprise integration.

ISO 19439:2006 Enterprise integration—Framework for enterprise modelling, is an international standard for enterprise modelling and enterprise integration developed by the International Organization for Standardization, based on CIMOSA and GERAM.

The GRAI method, GRAI is short for Graphs with Results and Actions Inter-related, and the further developed GRAI Integrated Methodology (GIM) is a modeling method of Enterprise modelling.

Enterprise control is the ability to combine control, intelligence and process management to enable business optimization that is inclusive of business and production operations. It combines the strength of both business processes and production operations processes. It is the deliberate act of synchronizing business strategy with operational execution in real-time to enable closed loop business control across an enterprise.

Model Driven Interoperability (MDI) is a methodological framework, which provides a conceptual and technical support to make interoperable enterprises using ontologies and semantic annotations, following model driven development (MDD) principles.

Mark Stephen Fox is a Canadian computer scientist, Professor of Industrial Engineering and Distinguished Professor of Urban Systems Engineering at the University of Toronto, known for the development of Constraint Directed Scheduling in the 1980s and the TOVE Project to develop an ontological framework for enterprise modeling and enterprise integration in the 1990s.

Kurt Kosanke is a German engineer, retired IBM manager, director of the AMICE Consortium and consultant, known for his work in the field of enterprise engineering, Enterprise integration and CIMOSA.

Theodore Joseph Williams was an American engineer and Professor of Engineering at Purdue University, known for the development of the Purdue Enterprise Reference Architecture.

Guy Doumeingts is a French engineer, Emeritus professor at the University of Bordeaux 1 and former Director of "Laboratoire d’Automatique, Productique Signal et Image" control theory, known for the development of the GRAI method and his contributions to the field of Enterprise modelling.

Bruno Vallespir is a French engineer, and Professor of Enterprise Modelling at the University of Bordeaux, working in the fields of production management, performance evaluation and enterprise modeling.

The history of business architecture has its origins in the 1980s. In the next decades business architecture has developed into a discipline of "cross-organizational design of the business as a whole" closely related to enterprise architecture. The concept of business architecture has been proposed as a blueprint of the enterprise, as a business strategy, and also as the representation of a business design.