Related Research Articles

Indigo dye is an organic compound with a distinctive blue color. Indigo is a natural dye extracted from the leaves of some plants of the Indigofera genus, in particular Indigofera tinctoria. Dye-bearing Indigofera plants were commonly grown and used throughout the world, particularly in Asia, with the production of indigo dyestuff economically important due to the historical rarity of other blue dyestuffs.

Jeans are a type of pants or trousers made from denim or dungaree cloth. Often the term "jeans" refers to a particular style of trousers, called "blue jeans", with the addition of copper pocket rivets added by Jacob W. Davis in 1871 and patented by Davis and Levi Strauss on May 20, 1873. Prior to the patent, the term "blue jeans" had been long in use for various garments, constructed from blue-colored denim.

Denim is a sturdy cotton warp-faced textile in which the weft passes under two or more warp threads. This twill weave produces a diagonal ribbing that distinguishes it from cotton duck. Denim, as it is recognized today, was first produced in Nîmes, France.

Dyeing is the application of dyes or pigments on textile materials such as fibers, yarns, and fabrics with the goal of achieving color with desired color fastness. Dyeing is normally done in a special solution containing dyes and particular chemical material. Dye molecules are fixed to the fiber by absorption, diffusion, or bonding with temperature and time being key controlling factors. The bond between the dye molecule and fiber may be strong or weak, depending on the dye used. Dyeing and printing are different applications; in printing, color is applied to a localized area with desired patterns. In dyeing, it is applied to the entire textile.

Laundry detergent is a type of detergent used for cleaning dirty laundry (clothes). Laundry detergent is manufactured in powder and liquid form.

Textile printing is the process of applying color to fabric in definite patterns or designs. In properly printed fabrics the colour is bonded with the fibre, so as to resist washing and friction. Textile printing is related to dyeing but in dyeing properly the whole fabric is uniformly covered with one colour, whereas in printing one or more colours are applied to it in certain parts only, and in sharply defined patterns.

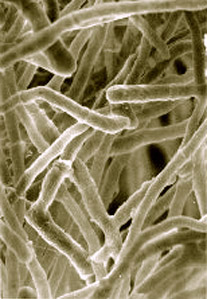

Trichoderma reesei is a mesophilic and filamentous fungus. It is an anamorph of the fungus Hypocrea jecorina. T. reesei can secrete large amounts of cellulolytic enzymes. Microbial cellulases have industrial application in the conversion of cellulose, a major component of plant biomass, into glucose.

Biotextiles are specialized materials engineered from natural or synthetic fibers. These textiles are designed to interact with biological systems, offering properties such as biocompatibility, porosity, and mechanical strength or are designed to be environmentally friendly for typical household applications. There are several uses for biotextiles since they are a broad category. The most common uses are for medical or household use. However, this term may also refer to textiles constructed from biological waste product. These biotextiles are not typically used for industrial purposes.

Stone washing is a textile manufacturing process used to give a newly manufactured cloth garment a worn appearance. The process became popular in the 1980s, as acid jeans gained popularity; however, stone washing has roots going back to 1960s surfer apparel. Stone washing also helps to increase the softness and flexibility of otherwise stiff and rigid fabrics such as canvas and denim. Although stone washing increases a fabric's flexibility, it shortens the life-span of the jeans. The process of stone washing can be costly, as freshly stone washed jeans must be washed many times in order to remove the grit from the process. Along with high production costs, stone washing can be detrimental to the environment, due to the excess grit that is removed as fabric is being stone washed. This leads many manufacturers to pursue other methods to achieve a distressed appearance.

Sustainable fashion is a term describing efforts within the fashion industry to reduce its environmental impacts, protect workers producing garments, and uphold animal welfare. Sustainability in fashion encompasses a wide range of factors, including cutting CO2 emissions, addressing overproduction, reducing pollution and waste, supporting biodiversity, and ensuring that garment workers are paid a fair wage and have safe working conditions.

In textile manufacturing, finishing refers to the processes that convert the woven or knitted cloth into a usable material and more specifically to any process performed after dyeing the yarn or fabric to improve the look, performance, or "hand" (feel) of the finish textile or clothing. The precise meaning depends on context.

Natural dyes are dyes or colorants derived from plants, invertebrates, or minerals. The majority of natural dyes are vegetable dyes from plant sources—roots, berries, bark, leaves, and wood—and other biological sources such as fungi.

Fibrolytic bacteria constitute a group of microorganisms that are able to process complex plant polysaccharides thanks to their capacity to synthesize cellulolytic and hemicellulolytic enzymes. Polysaccharides are present in plant cellular cell walls in a compact fiber form where they are mainly composed of cellulose and hemicellulose.

Wet Processing Engineering is one of the major streams in Textile Engineering or Textile manufacturing which refers to the engineering of textile chemical processes and associated applied science. The other three streams in textile engineering are yarn engineering, fabric engineering, and apparel engineering. The processes of this stream are involved or carried out in an aqueous stage. Hence, it is called a wet process which usually covers pre-treatment, dyeing, printing, and finishing.

Green textiles are fabrics or fibres produced to replace environmentally harmful textiles and minimise the ecological impact. Green textiles are part of the sustainable fashion and eco-friendly trends, providing alternatives to the otherwise pollution-heavy products of conventional textile industry, which is deemed the most ecologically damaging industry.

The fashion industry, particularly manufacture and use of apparel and footwear, is a significant driver of greenhouse gas emissions and plastic pollution. The rapid growth of fast fashion has led to around 80 billion items of clothing being consumed annually, with about 85% of clothes consumed in United States being sent to landfill.

Detergent enzymes are biological enzymes that are used with detergents. They catalyze the reaction between stains and the water solution, thus aiding stain removal and improving efficiency. Laundry detergent enzymes are the largest application of industrial enzymes.

Scouring is a preparatory treatment of certain textile materials. Scouring removes soluble and insoluble impurities found in textiles as natural, added and adventitious impurities, for example, oils, waxes, fats, vegetable matter, as well as dirt. Removing these contaminants through scouring prepares the textiles for subsequent processes such as bleaching and dyeing. Though a general term, "scouring" is most often used for wool. In cotton, it is synonymously called "boiling out", and in silk, and "boiling off".

Cold pad batch (CPB) is a method of dyeing textiles, typically cellulosic fibers such as cotton, in which the textile is impregnated with dye in a cold state, rather than being heated. High dye fixation and no thermal energy are the advantages of the CPB process. CPB-dyed fabrics are less expensive, have a softer hand feel, and have a cleaner surface than exhaust dyed materials. The process may take up to 12 hours in the batching process, depending on the depth of the shade. The disadvantage is that batching is a time-consuming and lengthy process. The process was developed in 1960.

Discharge printing is a textile printing technique that involves the application of a discharging agent to strip dye from already-dyed cloth in order to produce a printed pattern, which can be either white or colored. It is a method to imprint a design onto dyed fabric. The print pattern is achieved by applying a substance capable of removing the color, such as chlorine or hydrosulfite, to create a white or light pattern on a darker-hued dyed background. A dischargeable dye is employed for dischargeable printing.

References

- 1 2 3 4 Patra, A.K.; Madhu, Amit; Bala, Neeraj (2018). "Enzyme washing of indigo and sulphur dyed denim". Fashion and Textiles. 5. doi: 10.1186/s40691-017-0126-9 .

- ↑ Mosjov, Kiro (2014). "Trends in Bio-Processing of Textiles: A Review". Advanced Technologies. 3 (2): 135–138.

- ↑ ENZYME WASHING INFORMATION

- 1 2 Bhat, M.K. (2000). "Cellulases and related enzymes in biotechnology". Biotechnology Advances. 18 (5): 355–383. doi:10.1016/S0734-9750(00)00041-0. PMID 14538100.

- 1 2 3 Trotman, Samuel. "Future of Wash: Sustainable Solutions for Stone and Acid Wash in the Denim Industry". Denim Dudes. Retrieved 14 November 2020.

- ↑ Marre, Kathleen. ""Stone" Washing Jeans: Cellulases". IUPUI Department of Biology.

- ↑ "Enzymes make your jeans less thirsty". Novozymes.