Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

A heat pump is a device that uses work to transfer heat from a cool space to a warm space by transferring thermal energy using a refrigeration cycle, cooling the cool space and warming the warm space. In cold weather a heat pump can move heat from the cool outdoors to warm a house; the pump may also be designed to move heat from the house to the warmer outdoors in warm weather. As they transfer heat rather than generating heat, they are more energy-efficient than other ways of heating or cooling a home.

The coefficient of performance or COP of a heat pump, refrigerator or air conditioning system is a ratio of useful heating or cooling provided to work (energy) required. Higher COPs equate to higher efficiency, lower energy (power) consumption and thus lower operating costs. The COP is used in thermodynamics.

A chiller is a machine that removes heat from a liquid coolant via a vapor-compression, absorption refrigeration, or absorption refrigeration cycles. This liquid can then be circulated through a heat exchanger to cool equipment, or another process stream. As a necessary by-product, refrigeration creates waste heat that must be exhausted to ambience, or for greater efficiency, recovered for heating purposes. Vapor compression chillers may use any of a number of different types of compressors. Most common today are the hermetic scroll, semi-hermetic screw, or centrifugal compressors. The condensing side of the chiller can be either air or water cooled. Even when liquid cooled, the chiller is often cooled by an induced or forced draft cooling tower. Absorption and adsorption chillers require a heat source to function.

In the United States, the efficiency of air conditioners is often rated by the seasonal energy efficiency ratio (SEER) which is defined by the Air Conditioning, Heating, and Refrigeration Institute, a trade association, in its 2008 standard AHRI 210/240, Performance Rating of Unitary Air-Conditioning and Air-Source Heat Pump Equipment. A similar standard is the European seasonal energy efficiency ratio (ESEER).

Solar air conditioning, or "solar-powered air conditioning", refers to any air conditioning (cooling) system that uses solar power.

District cooling is the cooling equivalent of district heating. Working on broadly similar principles to district heating, district cooling delivers chilled water to buildings like offices and factories. In winter, the source for the cooling can often be seawater, so it is a cheaper resource than using electricity to run compressors for cooling. Alternatively, District Cooling can be provided by a Heat Sharing Network which enables each building on the circuit to use a heat pump to reject heat to an ambient ground temperature circuit.

A ground source heat pump is a heating/cooling system for buildings that use a type of heat pump to transfer heat to or from the ground, taking advantage of the relative constancy of temperatures of the earth through the seasons. Ground-source heat pumps (GSHPs) – or geothermal heat pumps (GHP), as they are commonly termed in North America – are among the most energy-efficient technologies for providing HVAC and water heating, using far less energy than can be achieved by burning a fuel in a boiler/furnace or by use of resistive electric heaters.

The annual fuel utilization efficiency is a thermal efficiency measure of space-heating furnaces and boilers. The AFUE differs from the true 'thermal efficiency' in that it is not a steady-state, peak measure of conversion efficiency, but instead attempts to represent the actual, season-long, average efficiency of that piece of equipment, including the operating transients. It is a dimensionless ratio of useful energy output to energy input, expressed as a percentage. For example, a 90% AFUE for a gas furnace means it outputs 90 BTUs of useful heating for every 100 BTUs of natural gas input. A higher AFUE means higher efficiency.

Heating seasonal performance factor (HSPF) is a term used in the heating and cooling industry. HSPF is specifically used to measure the efficiency of air source heat pumps.

Deep water source cooling (DWSC) or deep water air cooling is a form of air cooling for process and comfort space cooling which uses a large body of naturally cold water as a heat sink. It uses water at 4 to 10 degrees Celsius drawn from deep areas within lakes, oceans, aquifers or rivers, which is pumped through the one side of a heat exchanger. On the other side of the heat exchanger, cooled water is produced.

Free cooling is an economical method of using low external air temperatures to assist in chilling water, which can then be used for industrial processes, or air conditioning systems. The chilled water can either be used immediately or be stored for the short- or long-term. When outdoor temperatures are lower relative to indoor temperatures, this system utilizes the cool outdoor air as a free cooling source. In this manner, the system replaces the chiller in traditional air conditioning systems while achieving the same cooling result. Such systems can be made for single buildings or district cooling networks.

Trane is a manufacturer of commercial and residential heating, ventilation, and air conditioning (HVAC) systems, along with building management systems and controls. The company is a subsidiary of Trane Technologies, a company focused on manufacturing HVAC and refrigeration systems. Trane employs more than 29,000 people at 104 manufacturing locations in 28 countries, and has annual sales of more than US$8 billion.

HVAC is a major sub discipline of mechanical engineering. The goal of HVAC design is to balance indoor environmental comfort with other factors such as installation cost, ease of maintenance, and energy efficiency. The discipline of HVAC includes a large number of specialized terms and acronyms, many of which are summarized in this glossary.

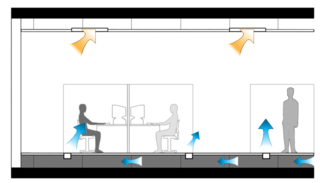

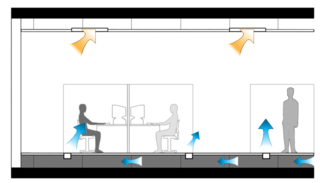

Underfloor air distribution (UFAD) is an air distribution strategy for providing ventilation and space conditioning in buildings as part of the design of a HVAC system. UFAD systems use an underfloor supply plenum located between the structural concrete slab and a raised floor system to supply conditioned air to supply outlets, located at or near floor level within the occupied space. Air returns from the room at ceiling level or the maximum allowable height above the occupied zone.

Variable refrigerant flow (VRF), also known as variable refrigerant volume (VRV), is an HVAC technology invented by Daikin Industries, Ltd. in 1982. Similar to ductless mini-split systems, VRFs use refrigerant as the primary cooling and heating medium, and is usually less complex than conventional chiller-based systems. This refrigerant is conditioned by one or more condensing units, and is circulated within the building to multiple indoor units. VRF systems, unlike conventional chiller-based systems, allow for varying degrees of cooling in more specific areas, may supply hot water in a heat recovery configuration without affecting efficiency, and switch to heating mode during winter without additional equipment, all of which may allow for reduced energy consumption. Also, air handlers and large ducts are not used which can reduce the height above a dropped ceiling as well as structural impact as VRF uses smaller penetrations for refrigerant pipes instead of ducts.

Eurovent is Europe's Industry Association for Indoor Climate (HVAC), Process Cooling, and Food Cold Chain Technologies. Its members from throughout Europe represent more than 1.000 companies, the majority small and medium-sized manufacturers. The organisation's activities are based on highly valued democratic decision-making principles, ensuring a level playing field for the entire industry independent from organisation sizes or membership fees.

In air conditioning, an inverter compressor is a compressor that is operated with an inverter.

The Glossary of Geothermal Heating and Cooling provides definitions of many terms used within the Geothermal heat pump industry. The terms in this glossary may be used by industry professionals, for education materials, and by the general public.

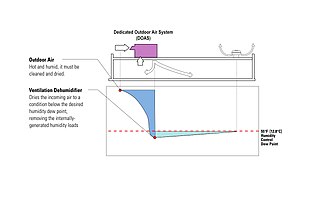

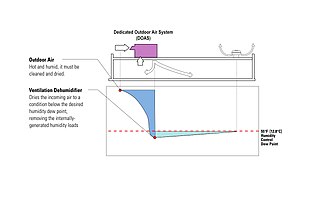

Moisture Removal Efficiency (MRE) is a measure of the energy efficiency of any dehumidification process. Moisture removal efficiency is the water vapor removed from air at a defined inlet air temperature and humidity, divided by the total energy consumed by the dehumidification equipment during the same time period, including all fan and pump energy needed to move air and fluids through the system.