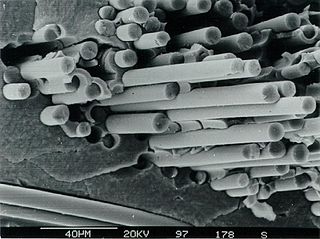

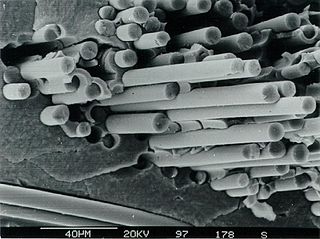

Carbon fibers or carbon fibres are fibers about 5 to 10 micrometers (0.00020–0.00039 in) in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, motorsports, and other competition sports. However, they are relatively expensive compared to similar fibers, such as glass fiber, basalt fibers, or plastic fibers.

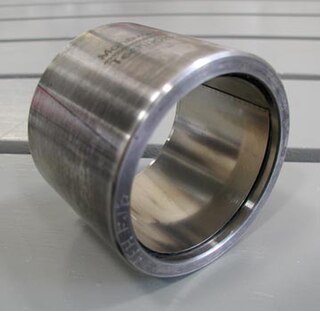

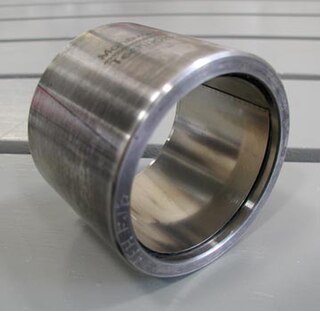

A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or the directions of the loads (forces) applied to the parts.

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening ("curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure, or mixing with a catalyst. Heat is not necessarily applied externally, but is often generated by the reaction of the resin with a curing agent. Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network.

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a permanently assembled object created using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used.

A plain bearing, or more commonly sliding contact bearing and slide bearing, is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the journal slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe.

The Timken Company is a global manufacturer of bearings and power transmission products. Timken operates from 42 countries.

Ultra-high-molecular-weight polyethylene is a subset of the thermoplastic polyethylene. Also known as high-modulus polyethylene (HMPE), it has extremely long chains, with a molecular mass usually between 3.5 and 7.5 million amu. The longer chain serves to transfer load more effectively to the polymer backbone by strengthening intermolecular interactions. This results in a very tough material, with the highest impact strength of any thermoplastic presently made.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware, automobiles, and bicycle frames. Advancements in powder coating technology like UV-curable powder coatings allow for other materials such as plastics, composites, carbon fiber, and MDF to be powder coated due to the minimum heat and oven dwell time required to process these components.

Mohawk Innovative Technology, Inc. is an American product and research and development technology company that develops oil-free foil bearings, magnetic bearings and non-contacting foil seals for high-speed rotating machinery, such as gas turbine engines, turbochargers, compressors, cryogenic pumps, variable high-speed motors/generators and machines.

Polymer engineering is generally an engineering field that designs, analyses, and modifies polymer materials. Polymer engineering covers aspects of the petrochemical industry, polymerization, structure and characterization of polymers, properties of polymers, compounding and processing of polymers and description of major polymers, structure property relations and applications.

Dry lubricants or solid lubricants are materials that, despite being in the solid phase, are able to reduce friction between two surfaces sliding against each other without the need for a liquid oil medium.

A thermoset polymer matrix is a synthetic polymer reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as glass-reinforced plastic radar domes on aircraft and graphite-epoxy payload bay doors on the Space Shuttle.

In materials science, ceramic matrix composites (CMCs) are a subgroup of composite materials and a subgroup of ceramics. They consist of ceramic fibers embedded in a ceramic matrix. The fibers and the matrix both can consist of any ceramic material, whereby carbon and carbon fibers can also be regarded as a ceramic material.

Carbon fiber-reinforced polymers, carbon-fiber-reinforced polymers, carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic, also known as carbon fiber, carbon composite, or just carbon, are extremely strong and light fiber-reinforced plastics that contain carbon fibers. CFRPs can be expensive to produce, but are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructures of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications.

Technetics Group is one of six operating divisions of Enpro Industries, Inc., a producer of engineered industrial products for the processing and general manufacturing industries, worldwide.

Enpro is a US-based industrial technology company that designs and manufactures products and materials for technology-intensive sectors. The company serves industries such as semiconductors, aerospace, power generation, heavy-duty trucking, agricultural machinery, chemical processing, pulp and paper, and life sciences from 61 primary manufacturing facilities located in 12 countries, worldwide. It is organized under three segments: Sealing Technologies, Advanced Surface Technologies, and Engineered Materials.

A composite bearing is a bearing made from a combination of materials such as a resin reinforced with fibre and this may also include friction reducing lubricants and ingredients.

GreenMantra Technologies is a clean technology company that produces value-added synthetic waxes and specialty polymers from post-consumer and post-industrial recycled plastics. These products are used in various applications including roofing and paving, plastics processing, and plastics composites. The company is focused on "up-cycling" recycled plastics into specialty materials, creating a more circular economy for plastics where they are beneficially reused rather than landfilled.

Polyetherketones are polymers whose molecular backbone contain alternating ketone (R-CO-R) and Ether (R-O-R) functionalities. The most common are Polyaryletherketones (PAEK), in which there is an aryl group linked in the (1–4)-position between each of the functional groups. The backbone, which is thus very rigid, gives the materials very high glass transition and melting temperatures compared to other plastics.

Plastic coating is a term that is commonly used in technology but is nevertheless ambiguous. It can be understood to mean the coating of plastic or the coating of other materials with plastics.