Related Research Articles

Calico is a heavy plain-woven textile made from unbleached, and often not fully processed, cotton. It may also contain unseparated husk parts. The fabric is far coarser than muslin, but less coarse and thick than canvas or denim. However, it is still very cheap owing to its unfinished and undyed appearance.

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms.

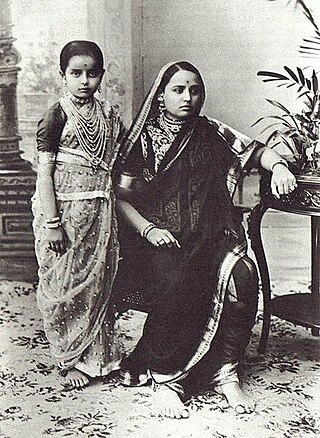

A sari is a women's garment from the Indian subcontinent, that consists of an un-stitched stretch of woven fabric arranged over the body as a robe, with one end attached to the waist, while the other end rests over one shoulder as a stole (shawl), sometimes baring a part of the midriff. It may vary from 4.1 to 8.2 metres in length, and 60 to 120 centimetres in breadth, and is form of ethnic wear in India, Sri Lanka, Nepal, Bangladesh and Pakistan. There are various names and styles of sari manufacture and draping, the most common being the Nivi style. The sari is worn with a fitted bodice also called a choli and a petticoat called ghagra, parkar, or ul-pavadai. It remains fashionable in the Indian Subcontinent today.

Khadi, derived from khaddar, is a hand-spun and woven natural fibre cloth promoted by Mahatma Gandhi as swadeshi (self-sufficiency) for the freedom struggle of the Indian subcontinent, and the term is used throughout India, Pakistan and Bangladesh. The first piece of the hand-woven cloth was manufactured in the Sabarmati Ashram during 1917–18. The coarseness of the cloth led Gandhi to call it khadi. The cloth is made from cotton, but it may also include silk or wool, which are all spun into yarn on a charkha. It is a versatile fabric that remains cool in summer and warm in winter. To improve its appearance, khadi is sometimes starched to give it a stiffer feel. It is widely accepted in various fashion circles.

Bandhani is a type of tie-dye textile decorated by plucking the cloth with the fingernails into many tiny bindings that form a figurative design. The term bandhani is derived from the Sanskrit verbal root bandh. Today, most Bandhani making centers are situated in Gujarat, Rajasthan, Sindh, Punjab region and in Tamil Nadu where it is known as Sungudi. It is known as chunri in Pakistan. Earliest evidence of Bandhani dates back to Indus Valley civilization where dyeing was done as early as 4000 B.C. The earliest example of the most pervasive type of Bandhani dots can be seen in the 6th century paintings depicting the life of Buddha found on the wall of Cave at Ajanta. Bandhani is also known as Bandhej Saree, Bandhni, Piliya, and Chungidi in Tamil and regional dialects. Other tying techniques include Mothra, Ekdali and Shikari depending on the manner in which the cloth is tied. The final products are known with various names including Khombi, Ghar Chola, Patori and Chandrokhani.

A Banarasi sari is a sari made in Varanasi, an ancient city which is also called Benares (Banaras). The saris are among the finest saris in India and are known for their gold and silver brocade or zari, fine silk and opulent embroidery. The saris are made of finely woven silk and are decorated with intricate designs, and, because of these engravings, are relatively heavy.

Longcloth refers to a plain cotton cloth originally made in comparatively long pieces.

Piña is a traditional Philippine fiber made from the leaves of the pineapple plant. Pineapples are indigenous to South America but have been widely cultivated in the Philippines since the 17th century, and used for weaving lustrous lace-like luxury textiles known as nipis fabric. The name is derived from Spanish piña, meaning "pineapple".

Silk In India, about 97% of the raw mulberry silk is produced in the Indian states of Karnataka, Andhra Pradesh, Tamil Nadu and West Bengal. Mysore and North Bangalore, the upcoming site of a US$20 million "Silk City", contribute to a majority of silk production. Another emerging silk producer is Tamil Nadu in the place in where mulberry cultivation is concentrated in Salem, Erode and Dharmapuri districts. Hyderabad, Andhra Pradesh and Gobichettipalayam, Tamil Nadu were the first locations to have automated silk reeling units.

Weaving and cloth trading communities of Western India particularly of Gujarat are called Vankar/Wankar/Vaniya. The four major woven fabrics produced by these communities are cotton, silk, khadi and linen. Today majority of these community members are not engaged in their ancestral weaving occupation still some population of these community contribute themselves in traditional handloom weaving of famous Patola of Patan, Kachchh shawl of Bhujodi in Kutch, Gharchola and Crotchet of Jamnagar, Zari of Surat, Mashroo of Patan and Mandvi in Kutch, Bandhani of Jamnagar, Anjar and Bhuj, Motif, Leheria, Dhamakda and Ajrak, Nagri sari, Tangaliya Shawl, Dhurrie, Kediyu, Heer Bharat, Abhala, Phento and art of Gudri. Vankar is described as a caste as well as a community.

Pochampally sari or Pochampalli ikat is a saree made in Bhoodan Pochampally, Yadadri Bhuvanagiri district, Telangana State, India. They have traditional geometric patterns in "Paagadu Bandhu" (Ikat) style of dyeing. The intricate geometric designs find their way into sarees and dress materials. The Indian government's official airplane company, Air India, has its cabin crew wear specially designed Pochampally silk sarees.

Handloom saris are a traditional textile art of Bangladesh and India. The production of handloom saris is important for economic development in rural India.

Kotpad Handloom is a vegetable-dyed fabric woven by the tribal weavers of the Mirgan community of Kotpad village in Koraput district, Odisha, India. Cotton sarees with solid border and Pata Anchal, duppatta with typical Buties / motifs, Scolrfs on cotton, silk, handloom stoles, and dress materials are all dyed with organic dyes. The natural dye is manufactured from the aul tree grown in this area. The Kotpad tussar silk saree with tribal art and Kotpad handloom fabrics with natural color is its specialty.

Bafta is a kind of calico, initially made in India.

Piece goods were the textile materials sold in cut pieces as per the buyer's specification. The piece goods were either cut from a fabric roll or produced with a certain length, also called yard goods. Various textiles such as cotton, wool, silk, etc., were traded in terms of piece goods. The prices were determined as per the fabric quality.

Alacha is a lightweight striped cloth made primarily of silk, sometimes cotton, or a mixture of both. The stripe pattern was evident on both sides of the fabric. A typical length of alacha is five yards. It was produced in various parts of India, for example Baikunthpur, Bihar. The cloth was popular in use for female garments such as dupattas (odhni), veils, and petticoats.

Dosuti was one of the coarser cotton piece goods produced in the Indian subcontinent. Originally, it was a handspun and handloom cloth made in the villages. Punjab had various cotton qualities during the 19th century. All were distinguished by their weight, thickness, and the yarn. Dosuti was a cloth made by running two yarns in warp and weft as its name refers to Do(double) Suti. India's Eastern side was famous for more delicate cotton materials such as Dacca muslins, and Punjab and Gujarat were famous for coarser cotton textile piece goods. Dosuti was a thick cotton material used for rough usages, such as duster. The other contemporary cotton products were Eksuti, Tinsuti, and Chausuti, etc.

Niwar is a coarse, narrow, thick tape that was initially made of cotton only. Niwar is a textile product produced on tape looms and classified as a narrow-width fabric. Baden Henry Powell referred to it as "broad coarse tape", a product of the jail industry. In his book Handbook of the Manufactures and Arts of the Punjab, Powell classified niwar under the category of "tape, string, and miscellaneous cotton products". A weaver of this tape is called a niwar-baf.

Dorea was a type of striped or check patterned cloth made in the Indian subcontinent. The continued striped Dorea was a simplest form of Dorea.

Matka cloth was a kind of coarse silk from the Indian subcontinent. It was mainly produced with pierced cocoons. A pierced cocoon is one from which the moth of the silkworm has emerged and damaged the cocoon. The silk from these cocoons is spun, not reeled. The fabric made from these yarns is known as "Matka cloth."

References

- ↑ Sohrābjī, munshī Ḍōsābhāī (1873). A New Self-instructing Work Entitled Idiomatic Sentences, (in Urdu). Printed at the "Reporters' Press," by Merwanjee Nowrojee, Daboo. p. 426.

- 1 2 Nevill, H. R. (1911). Bareilly - A Gazetteer. p. 66.

- 1 2 H.R. Nevill (1908). Jaunpur: a Gazetteer being volume XXVIII of the District Gazetteers of the United Provinces of Agra and Oudh. Allahabad, Superintendent Government Press. p. 282.

- 1 2 O’malley, L. s s (1906). Bengal District Gazetteers Gaya. p. 179.

- 1 2 O’Malley, Lewis Sydney Steward (1912). Bengal District Gazetteer : Gaya. Bengal Secretariat Book Depot, Calcutta. p. 22.

- ↑ Luard, C. E. (1864). Eastern States Gazetteers (bundelkhand). p. 395.

- ↑ PAGE 137 Competition of powerlooms has, therefore, resulted in the reduction of the remuneration of gaji weavers. Wealth of Gujarat Anantray Bhagwanji Trivedi · 1943

- ↑ Shore, R. (1909). Medico Topographical Account Of Mewar. p. 20.