Related Research Articles

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold that contains a negative impression of the intended shape. The metal is poured into the mold through a hollow channel called a sprue. The metal and mold are then cooled, and the metal part is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods.

The Linotype machine is a "line casting" machine used in printing which is manufactured and sold by the former Mergenthaler Linotype Company and related companies. It was a hot metal typesetting system that cast lines of metal type for individual uses. Linotype became one of the mainstay methods to set type, especially small-size body text, for newspapers, magazines, and posters from the late 19th century to the 1970s and 1980s, when it was largely replaced by phototypesetting and digital typesetting. The name of the machine comes from the fact that it produces an entire line of metal type at once, hence a line-o'-type. It was a significant improvement over the previous industry standard of manual, letter-by-letter typesetting using a composing stick and shallow subdivided trays, called "cases".

An ingot is a piece of relatively pure material, usually metal, that is cast into a shape suitable for further processing. In steelmaking, it is the first step among semi-finished casting products. Ingots usually require a second procedure of shaping, such as cold/hot working, cutting, or milling to produce a useful final product. Non-metallic and semiconductor materials prepared in bulk form may also be referred to as ingots, particularly when cast by mold based methods. Precious metal ingots can be used as currency, or as a currency reserve, as with gold bars.

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand — known as casting sand — as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. In 2003, over 60% of all metal castings were produced via sand casting.

Centrifugal casting in silversmithing is a casting technique where a small mould is poured, then spun on the end of an arm. The centrifugal force thus generated encourages a successful pour.

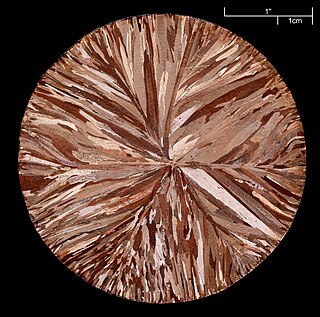

Spin casting, also known as centrifugal rubber mold casting (CRMC), is a method of utilizing inertia to produce castings from a rubber mold. Typically, a disc-shaped mold is spun along its central axis at a set speed. The casting material, usually molten metal or liquid thermoset plastic, is then poured in through an opening at the top-center of the mold. The filled mold then continues to spin as the metal solidifies.

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals processed are aluminum and cast iron. However, other metals, such as bronze, brass, steel, magnesium, and zinc, are also used to produce castings in foundries. In this process, parts of desired shapes and sizes can be formed.

Pot metal is an alloy of low-melting point metals that manufacturers use to make fast, inexpensive castings. The term "pot metal" came about due to the practice at automobile factories in the early 20th century of gathering up non-ferrous metal scraps from the manufacturing processes and melting them in one pot to form into cast products. Small amounts of iron often made it into the castings but never in significant quantity because too much iron would raise the melting point too high for simple casting operations.

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary molds to form ingots. Since then, "continuous casting" has evolved to achieve improved yield, quality, productivity and cost efficiency. It allows lower-cost production of metal sections with better quality, due to the inherently lower costs of continuous, standardised production of a product, as well as providing increased control over the process through automation. This process is used most frequently to cast steel. Aluminium and copper are also continuously cast.

Investment casting is an industrial process based on lost-wax casting, one of the oldest known metal-forming techniques. The term "lost-wax casting" can also refer to modern investment casting processes.

Fusible core injection molding, also known as lost core injection molding, is a specialized plastic injection molding process used to mold internal cavities or undercuts that are not possible to mold with demoldable cores. Strictly speaking the term "fusible core injection molding" refers to the use of a fusible alloy as the core material; when the core material is made from a soluble plastic the process is known as soluble core injection molding. This process is often used for automotive parts, such as intake manifolds and brake housings, however it is also used for aerospace parts, plumbing parts, bicycle wheels, and footwear.

In casting, a pattern is a replica of the object to be cast, used to form the sand mould cavity into which molten metal is poured during the casting process. Once the pattern has been used to form the sand mould cavity, the pattern is then removed, Molten metal is then poured into the sand mould cavity to produce the casting. The pattern is non consumable and can be reused to produce further sand moulds almost indefinitely.

A bench jeweler is an artisan who uses a combination of skills to make and repair jewelry. Some of the more common skills that a bench jeweler might employ include antique restoration, silversmithing, goldsmithing, stone setting, engraving, fabrication, wax carving, lost-wax casting, electroplating, forging, & polishing.

Permanent mold casting is a metal casting process that employs reusable molds, usually made from metal. The most common process uses gravity to fill the mold, however gas pressure or a vacuum are also used. A variation on the typical gravity casting process, called slush casting, produces hollow castings. Common casting metals are aluminium, magnesium, and copper alloys. Other materials include tin, zinc, and lead alloys and iron and steel are also cast in graphite molds.

Plaster mold casting is a metalworking casting process similar to sand casting except the molding material is plaster of Paris instead of sand. Like sand casting, plaster mold casting is an expendable mold process, however it can only be used with non-ferrous materials. It is used for castings as small as 30 g (1 oz) to as large as 7–10 kg (15–22 lb). Generally, the form takes less than a week to prepare. Production rates of 1–10 units/hr can be achieved with plaster molds.

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various time setting materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC.

Resin casting is a method of plastic casting where a mold is filled with a liquid synthetic resin, which then hardens. It is primarily used for small-scale production like industrial prototypes and dentistry. It can be done by amateur hobbyists with little initial investment, and is used in the production of collectible toys, models and figures, as well as small-scale jewellery production.

Centrifugal casting or rotocasting is a casting technique that is typically used to cast thin-walled cylinders. It is typically used to cast materials such as metals, glass, and concrete. A high quality is attainable by control of metallurgy and crystal structure. Unlike most other casting techniques, centrifugal casting is chiefly used to manufacture rotationally symmetric stock materials in standard sizes for further machining, rather than shaped parts tailored to a particular end-use.

Wheel construction refers to the making of wheels. Construction of wire-spoked wheels is generally termed as wheelbuilding, so wheel construction refers to construction of non-wire wheels, e.g. wheels of cars and other heavier vehicles. Wheels are constructed in a wide variety of designs using different materials, but in the early 21st century, aluminum and steel are most often used, with steel-made wheels being heavier and more durable than aluminum wheels. The performance of a wheel depends on the alloy and technique used to construct it. A wheel is usually made up of a rim, which connects with the tire, and a central disc, also known as the disc or spider, which connects the wheel to the vehicle. Wheels are usually of two types: semi-drop center (SDC), used in trucks, and drop center (DC), used in other vehicles.

References

- ↑ Pratip Kumar Gupta; J.E. Mannar (1969). Recent Developments in Non-ferrous Metals Technology: Nickel, lead, zinc, rare earth, and nuclear metals. National Metallurgical Laboratory (India). p. 102.

- ↑ Marcia Chamberlain (1976). Metal jewelry techniques. Watson-Guptill Publications. p. 79.

- ↑ Philip Morton (1970). Contemporary jewelry: a studio handbook. p. 205.