Related Research Articles

A nickel–metal hydride battery is a type of rechargeable battery. The chemical reaction at the positive electrode is similar to that of the nickel-cadmium cell (NiCd), with both using nickel oxide hydroxide (NiOOH). However, the negative electrodes use a hydrogen-absorbing alloy instead of cadmium. NiMH batteries can have two to three times the capacity of NiCd batteries of the same size, with significantly higher energy density, although only about half that of lithium-ion batteries.

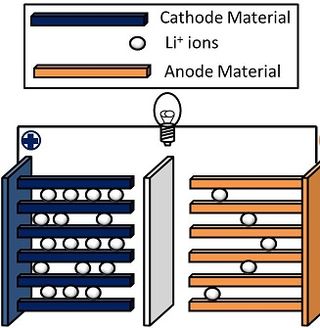

A lithium-ion or Li-ion battery is a type of rechargeable battery that uses the reversible intercalation of Li+ ions into electronically conducting solids to store energy. In comparison with other commercial rechargeable batteries, Li-ion batteries are characterized by higher specific energy, higher energy density, higher energy efficiency, a longer cycle life, and a longer calendar life. Also noteworthy is a dramatic improvement in lithium-ion battery properties after their market introduction in 1991: within the next 30 years, their volumetric energy density increased threefold while their cost dropped tenfold.

The lithium iron phosphate battery or LFP battery is a type of lithium-ion battery using lithium iron phosphate as the cathode material, and a graphitic carbon electrode with a metallic backing as the anode. Because of their low cost, high safety, low toxicity, long cycle life and other factors, LFP batteries are finding a number of roles in vehicle use, utility-scale stationary applications, and backup power. LFP batteries are cobalt-free. As of September 2022, LFP type battery market share for EVs reached 31%, and of that, 68% was from Tesla and Chinese EV maker BYD production alone. Chinese manufacturers currently hold a near monopoly of LFP battery type production. With patents having started to expire in 2022 and the increased demand for cheaper EV batteries, LFP type production is expected to rise further and surpass lithium nickel manganese cobalt oxides (NMC) type batteries in 2028.

Lithium iron phosphate or lithium ferro-phosphate (LFP) is an inorganic compound with the formula LiFePO

4. It is a gray, red-grey, brown or black solid that is insoluble in water. The material has attracted attention as a component of lithium iron phosphate batteries, a type of Li-ion battery. This battery chemistry is targeted for use in power tools, electric vehicles, solar energy installations and more recently large grid-scale energy storage.

Lithium cobalt oxide, sometimes called lithium cobaltate or lithium cobaltite, is a chemical compound with formula LiCoO

2. The cobalt atoms are formally in the +3 oxidation state, hence the IUPAC name lithium cobalt(III) oxide.

An electric vehicle battery is a rechargeable battery used to power the electric motors of a battery electric vehicle (BEV) or hybrid electric vehicle (HEV).

The lithium-titanate or lithium-titanium-oxide (LTO) battery is a type of rechargeable battery which has the advantage of being faster to charge than other lithium-ion batteries but the disadvantage of having a much lower energy density.

Cobalt is a chemical element; it has symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, produced by reductive smelting, is a hard, lustrous, silvery metal.

Research in lithium-ion batteries has produced many proposed refinements of lithium-ion batteries. Areas of research interest have focused on improving energy density, safety, rate capability, cycle durability, flexibility, and cost.

Usage of electric cars damage people’s health and the environment less than similar sized internal combustion engine cars. While aspects of their production can induce similar, less or different environmental impacts, they produce little or no tailpipe emissions, and reduce dependence on petroleum, greenhouse gas emissions, and deaths from air pollution. Electric motors are significantly more efficient than internal combustion engines and thus, even accounting for typical power plant efficiencies and distribution losses, less energy is required to operate an electric vehicle. Manufacturing batteries for electric cars requires additional resources and energy, so they may have a larger environmental footprint in the production phase. Electric vehicles also generate different impacts in their operation and maintenance. Electric vehicles are typically heavier and could produce more tire and road dust air pollution, but their regenerative braking could reduce such particulate pollution from brakes. Electric vehicles are mechanically simpler, which reduces the use and disposal of engine oil.

Huayou Cobalt Co., Ltd primarily operates as a supplier of cobalt and its associated products, such as cobalt tetroxide, cobalt oxide, cobalt carbonate, cobalt hydroxide, cobalt oxalate, cobalt sulfate, and cobalt monoxide. The company is headquartered in the Tongxiang Economic Development Zone of Zhejiang, China.

Simon David Moores is a British businessman and entrepreneur, specializing in the lithium ion battery and electric vehicle industry.

The lithium nickel cobalt aluminium oxides (abbreviated as Li-NCA, LNCA, or NCA) are a group of mixed metal oxides. Some of them are important due to their application in lithium ion batteries. NCAs are used as active material in the positive electrode (which is the cathode when the battery is discharged). NCAs are composed of the cations of the chemical elements lithium, nickel, cobalt and aluminium. The compounds of this class have a general formula LiNixCoyAlzO2 with x + y + z = 1. In case of the NCA comprising batteries currently available on the market, which are also used in electric cars and electric appliances, x ≈ 0,8, and the voltage of those batteries is between 3.6 V and 4.0 V, at a nominal voltage of 3.6 V or 3.7 V. A version of the oxides currently in use in 2019 is LiNi0,84Co0,12Al0,04O2.

Lithium nickel manganese cobalt oxides (abbreviated NMC, Li-NMC, LNMC, or NCM) are mixed metal oxides of lithium, nickel, manganese and cobalt with the general formula LiNixMnyCo1-x-yO2. These materials are commonly used in lithium-ion batteries for mobile devices and electric vehicles, acting as the positively charged cathode.

Lithium batteries are primary batteries that use lithium as an anode. This type of battery is also referred to as a lithium-ion battery and is most commonly used for electric vehicles and electronics. The first type of lithium battery was created by the British chemist M. Stanley Whittingham in the early 1970s and used titanium and lithium as the electrodes. Unfortunately, applications for this battery were limited by the high prices of titanium and the unpleasant scent that the reaction produced. Today's lithium ion battery, modeled after the Whittingham attempt by Akira Yoshino, was first developed in 1985.

Redwood Materials, Inc. is an American company headquartered in Carson City, Nevada. The company aims to recycle lithium-ion batteries and produce battery materials for electromobility and electrical storage systems. Redwood Materials was reported to have a valuation of about $3.7 billion as of July 2021.

This is a history of the lithium-ion battery.

The electric vehicle supply chain comprises the mining and refining of raw materials and the manufacturing processes that produce lithium ion batteries and other components for electric vehicles. The lithium-ion battery supply chain is a major component of the overall EV supply chain, and the battery accounts for 30–40% of the value of the vehicle. Lithium, cobalt, graphite, nickel, and manganese are all critical minerals that are necessary for electric vehicle batteries. There is rapidly growing demand for these materials because of growth in the electric vehicle market, which is driven largely by the proposed transition to renewable energy. Securing the supply chain for these materials is a major world economic issue. Recycling and advancement in battery technology are proposed strategies to reduce demand for raw materials. Supply chain issues could create bottlenecks, increase costs of EVs and slow their uptake.

Electra Battery Materials Corporation is a Canadian multinational corporation engaged in mining and refining raw materials for electric batteries. Electra owns and operates the first fully permitted metallurgical refinery in North America for producing battery-grade cobalt and nickel sulfate. The company also owns the Iron Creek cobalt-copper deposit in Lemhi County, Idaho, US.

References

- ↑ "Green metals". Manila Bulletin. Retrieved 2023-09-30.

- 1 2 3 4 5 6 7 8 "How to avoid a green-metals crunch". The Economist. ISSN 0013-0613 . Retrieved 2023-09-30.

- ↑ Saefong, Myra P. "EVs and Cleaner Energy Are Giving a Boost to Copper and Other 'Green' Metals". barrons. Retrieved 2023-09-30.