A knife is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least 2.5 million years ago, as evidenced by the Oldowan tools. Originally made of wood, bone, and stone, over the centuries, in step with improvements in both metallurgy and manufacturing, knife blades have been made from copper, bronze, iron, steel, ceramic, and titanium. Most modern knives have either fixed or folding blades; blade patterns and styles vary by maker and country of origin.

A chisel is a wedged hand tool with a characteristically shaped cutting edge on the end of its blade, for carving or cutting a hard material. The tool can be used by hand, struck with a mallet, or applied with mechanical power. The handle and blade of some types of chisel are made of metal or wood with a sharp edge in it.

A blade is the sharp, cutting portion of a tool, weapon, or machine, specifically designed to puncture, chop, slice, or scrape surfaces or materials. Blades are typically made from materials that are harder than those they are intended to cut. This includes early examples made from flaked stones like flint or obsidian, evolving through the ages into metal forms like copper, bronze, and iron, and culminating in modern versions made from steel or ceramics. Serving as one of humanity's oldest tools, blades continue to have wide-ranging applications, including in combat, cooking, and various other everyday and specialized tasks.

A Japanese kitchen knife is a type of kitchen knife used for food preparation. These knives come in many different varieties and are often made using traditional Japanese blacksmithing techniques. They can be made from stainless steel, or hagane, which is the same kind of steel used to make Japanese swords. Most knives are referred to as hōchō or the variation -bōchō in compound words but can have other names including -kiri. There are four general categories used to distinguish the Japanese knife designs: handle, blade grind, steel, and construction.

Yanagi-ba-bōchō, Yanagiba, or yanagi, is a long and thin knife used in the Japanese cuisine. It is the typical example of the sashimibōchō used to slice fish for sashimi and nigirizushi.

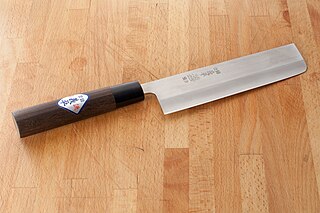

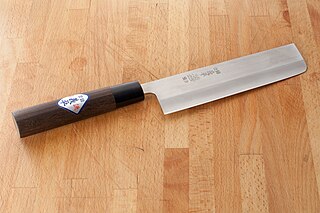

Usuba bōchō is the traditional vegetable knife for the professional Japanese chef. Like other Japanese professional knives, usuba are chisel ground, and have a bevel on the front side, and have a hollow ground urasuki on the back side. Usuba characteristically have a flat edge, with little or no curve, and are tall, to allow knuckle clearance when chopping on a cutting board. Usuba literally means "thin blade" indicating its relative thinness compared to other knives, required for cutting through firm vegetables without cracking them. Due to its height and straight edge, usuba are also used for specialized cuts such as katsuramuki, shaving a vegetable cylinder into a thin sheet.

A drawknife is a traditional woodworking hand tool used to shape wood by removing shavings. It consists of a blade with a handle at each end. The blade is much longer than it is deep. It is pulled or "drawn" toward the user.

A kitchen knife is any knife that is intended to be used in food preparation. While much of this work can be accomplished with a few general-purpose knives – notably a large chef's knife, a tough cleaver, a small paring knife and some sort of serrated blade – there are also many specialized knives that are designed for specific tasks. Kitchen knives can be made from several different materials.

In cooking, a chef's knife, also known as a cook's knife, is a cutting tool used in food preparation. The chef's knife was originally designed primarily to slice and disjoint large cuts of beef. Today it is the primary general utility knife for most Western cooks.

The santoku bōchō(Japanese: 三徳包丁, 'three virtues knife' or 'three uses knife') or bunka bōchō(文化包丁) is a general-purpose kitchen knife originating in Japan. Its blade is typically between 13 and 20 cm long, and has a flat edge. The santoku has a sheepsfoot blade that curves down an angle approaching 60 degrees at the point. The bunka bōchō, however, has a k-tip. The term santoku may refer to the wide variety of ingredients that the knife can handle: fish, meat, and vegetables, or to the tasks it can perform: chopping, dicing, and slicing, with either interpretation indicating a multi-use, general-purpose kitchen knife. The term bunka, refers to how it is used for the cultural food of Japan. The blade and handle of the santoku are designed to work in harmony by matching the blade's width and weight to the weight of the tang and the handle.

A straight razor is a razor with a blade that can fold into its handle. They are also called open razors and cut-throat razors. The predecessors of the modern straight razors include bronze razors, with cutting edges and fixed handles, produced by craftsmen from Ancient Egypt during the New Kingdom. Solid gold and copper razors were also found in Ancient Egyptian tombs dating back to the 4th millennium BC.

Japanese carpentry was developed more than a millennium ago that is known for its ability to create everything from temples to houses to tea houses to furniture by wood with the use of few nails.

Sharpening stones, or whetstones, are used to sharpen the edges of steel tools such as knives through grinding and honing.

Sharpening is the process of creating or refining the edge joining two non-coplanar faces into a converging apex, thereby creating an edge of appropriate shape on a tool or implement designed for cutting. Sharpening is done by removing material on an implement with an abrasive substance harder than the material of the implement, followed sometimes by processes to polish/hone the sharp surface to increase smoothness.

The primary grind is where a knife first begins to narrow into a cutting edge from the thickness of the main stock of the blade. The cross-sectional shape of the blade of a knife or sword is made up of different planes, or grinds. The sharp, cutting edge of the blade is often further ground at a secondary, or 'edge', bevel. This allows the blade to have more functions than otherwise possible with a strictly wedge or chisel shape.

Knife sharpening is the process of making a knife or similar tool sharp by grinding against a hard, rough surface, typically a stone, or a flexible surface with hard particles, such as sandpaper. Additionally, a leather razor strop, or strop, is often used to straighten and polish an edge.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

The term blade geometry refers to the physical properties of a sword blade: cross-section and taper.

Knife indentation is done away from the edge of a kitchen knife. A knife most simply has either a rectangular or wedge-shaped cross-section (sabre-grind v. flat-grind, but may also have concave indentations or hollows, whose purpose is to reduce adhesion of the food to the blade, so producing a cleaner and easier cut. This is widely found in Japanese knives, and in the West is particularly found in meat carving knives, though also in knives for soft cheese, and some use for vegetables.

The splitting band knife is a kind of knife used in several fields including: tannery, EVA/rubber, foam, cork, shoe and leather goods, paper, carpet and other soft sheet materials. It is a power tool which is very similar in operation to a band saw, with an endless loop blade; the material to be cut is supported by a flat table.