In organic chemistry, isocyanate is the functional group with the formula R−N=C=O. Organic compounds that contain an isocyanate group are referred to as isocyanates. An organic compound with two isocyanate groups is known as a diisocyanate. Diisocyanates are manufactured for the production of polyurethanes, a class of polymers.

Personal protective equipment (PPE) is protective clothing, helmets, goggles, or other garments or equipment designed to protect the wearer's body from injury or infection. The hazards addressed by protective equipment include physical, electrical, heat, chemical, biohazards, and airborne particulate matter. Protective equipment may be worn for job-related occupational safety and health purposes, as well as for sports and other recreational activities. Protective clothing is applied to traditional categories of clothing, and protective gear applies to items such as pads, guards, shields, or masks, and others. PPE suits can be similar in appearance to a cleanroom suit.

An occupational injury is bodily damage resulting from working. The most common organs involved are the spine, hands, the head, lungs, eyes, skeleton, and skin. Occupational injuries can result from exposure to occupational hazards, such as temperature, noise, insect or animal bites, blood-borne pathogens, aerosols, hazardous chemicals, radiation, and occupational burnout.

Occupational hygiene is the anticipation, recognition, evaluation, control, and confirmation (ARECC) of protection from risks associated with exposures to hazards in, or arising from, the workplace that may result in injury, illness, impairment, or affect the well-being of workers and members of the community. These hazards or stressors are typically divided into the categories biological, chemical, physical, ergonomic and psychosocial. The risk of a health effect from a given stressor is a function of the hazard multiplied by the exposure to the individual or group. For chemicals, the hazard can be understood by the dose response profile most often based on toxicological studies or models. Occupational hygienists work closely with toxicologists for understanding chemical hazards, physicists for physical hazards, and physicians and microbiologists for biological hazards. Environmental and occupational hygienists are considered experts in exposure science and exposure risk management. Depending on an individual's type of job, a hygienist will apply their exposure science expertise for the protection of workers, consumers and/or communities.

Chloroprene (IUPAC name 2-chlorobuta-1,3-diene) is a chemical compound with the molecular formula CH2=CCl−CH=CH2. Chloroprene is a colorless volatile liquid, almost exclusively used as a monomer for the production of the polymer polychloroprene, better known as neoprene, a type of synthetic rubber.

Vibration white finger (VWF), also known as hand-arm vibration syndrome (HAVS) or dead finger, is a secondary form of Raynaud's syndrome, an industrial injury triggered by continuous use of vibrating hand-held machinery. Use of the term vibration white finger has generally been superseded in professional usage by broader concept of HAVS, although it is still used by the general public. The symptoms of vibration white finger are the vascular component of HAVS.

An occupational hazard is a hazard experienced in the workplace. This encompasses many types of hazards, including chemical hazards, biological hazards (biohazards), psychosocial hazards, and physical hazards. In the United States, the National Institute for Occupational Safety and Health (NIOSH) conduct workplace investigations and research addressing workplace health and safety hazards resulting in guidelines. The Occupational Safety and Health Administration (OSHA) establishes enforceable standards to prevent workplace injuries and illnesses. In the EU, a similar role is taken by EU-OSHA.

Musculoskeletal disorders (MSDs) are injuries or pain in the human musculoskeletal system, including the joints, ligaments, muscles, nerves, tendons, and structures that support limbs, neck and back. MSDs can arise from a sudden exertion, or they can arise from making the same motions repeatedly, or from repeated exposure to force, vibration, or awkward posture. Injuries and pain in the musculoskeletal system caused by acute traumatic events like a car accident or fall are not considered musculoskeletal disorders. MSDs can affect many different parts of the body including upper and lower back, neck, shoulders and extremities. Examples of MSDs include carpal tunnel syndrome, epicondylitis, tendinitis, back pain, tension neck syndrome, and hand-arm vibration syndrome.

Control banding is a qualitative or semi-quantitative risk assessment and management approach to promoting occupational health and safety. It is intended to minimize worker exposures to hazardous chemicals and other risk factors in the workplace and to help small businesses by providing an easy-to-understand, practical approach to controlling hazardous exposures at work.

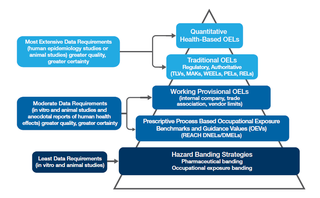

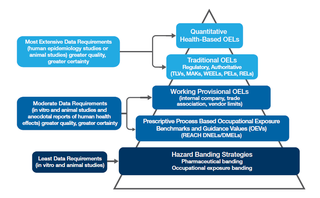

An occupational exposure limit is an upper limit on the acceptable concentration of a hazardous substance in workplace air for a particular material or class of materials. It is typically set by competent national authorities and enforced by legislation to protect occupational safety and health. It is an important tool in risk assessment and in the management of activities involving handling of dangerous substances. There are many dangerous substances for which there are no formal occupational exposure limits. In these cases, hazard banding or control banding strategies can be used to ensure safe handling.

Workplace health surveillance or occupational health surveillance (U.S.) is the ongoing systematic collection, analysis, and dissemination of exposure and health data on groups of workers. The Joint ILO/WHO Committee on Occupational Health at its 12th Session in 1995 defined an occupational health surveillance system as "a system which includes a functional capacity for data collection, analysis and dissemination linked to occupational health programmes".

Prevention through design (PtD), also called safety by design usually in Europe, is the concept of applying methods to minimize occupational hazards early in the design process, with an emphasis on optimizing employee health and safety throughout the life cycle of materials and processes. It is a concept and movement that encourages construction or product designers to "design out" health and safety risks during design development. The process also encourages the various stakeholders within a construction project to be collaborative and share the responsibilities of workers' safety evenly. The concept supports the view that along with quality, programme and cost; safety is determined during the design stage. It increases the cost-effectiveness of enhancements to occupational safety and health.

A physical hazard is an agent, factor or circumstance that can cause harm with contact. They can be classified as type of occupational hazard or environmental hazard. Physical hazards include ergonomic hazards, radiation, heat and cold stress, vibration hazards, and noise hazards. Engineering controls are often used to mitigate physical hazards.

The Control of Vibration at Work Regulations 2005 are a set of regulations created under the Health and Safety at Work etc. Act 1974 which came into force in Great Britain on 6 July 2005. The regulations place a duty on employers to reduce the risk to their employees’ health from exposure to vibration whether this is caused by the use of hand-held or hand-guided power equipment, holding materials which are being processed by machines or which is caused by the sitting or standing on industrial machines or vehicles.

Occupational hearing loss (OHL) is hearing loss that occurs as a result of occupational hazards, such as excessive noise and ototoxic chemicals. Noise is a common workplace hazard, and recognized as the risk factor for noise-induced hearing loss and tinnitus but it is not the only risk factor that can result in a work-related hearing loss. Also, noise-induced hearing loss can result from exposures that are not restricted to the occupational setting.

Ergonomic hazards are physical conditions that may pose a risk of injury to the musculoskeletal system due to poor ergonomics. These hazards include awkward or static postures, high forces, repetitive motion, or short intervals between activities. The risk of injury is often magnified when multiple factors are present.

Engineering controls are strategies designed to protect workers from hazardous conditions by placing a barrier between the worker and the hazard or by removing a hazardous substance through air ventilation. Engineering controls involve a physical change to the workplace itself, rather than relying on workers' behavior or requiring workers to wear protective clothing.

Occupational dust exposure occurs when small particles are generated at the workplace through the disturbance/agitation of rock/mineral, dry grain, timber, fiber, or other material. When these small particles become suspended in the air, they can pose a risk to the health of those who breath in the contaminated air.

Hazard substitution is a hazard control strategy in which a material or process is replaced with another that is less hazardous. Substitution is the second most effective of the five members of the hierarchy of hazard controls in protecting workers, after elimination. Substitution and elimination are most effective early in the design process, when they may be inexpensive and simple to implement, while for an existing process they may require major changes in equipment and procedures. The concept of prevention through design emphasizes integrating the more effective control methods such as elimination and substitution early in the design phase.

Occupational exposure banding, also known as hazard banding, is a process intended to quickly and accurately assign chemicals into specific categories (bands), each corresponding to a range of exposure concentrations designed to protect worker health. These bands are assigned based on a chemical’s toxicological potency and the adverse health effects associated with exposure to the chemical. The output of this process is an occupational exposure band (OEB). Occupational exposure banding has been used by the pharmaceutical sector and by some major chemical companies over the past several decades to establish exposure control limits or ranges for new or existing chemicals that do not have formal OELs. Furthermore, occupational exposure banding has become an important component of the Hierarchy of Occupational Exposure Limits (OELs).