A flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength ; for easy attachment/transfer of contact force with another object ; or for stabilizing and guiding the movements of a machine or its parts. Flanges are often attached using bolts in the pattern of a bolt circle. The term "flange" is also used for a kind of tool used to form flanges.

A fishing line is a flexible, high-tensile cord used in angling to tether and pull in fish, in conjunction with at least one hook. Fishing lines are usually pulled by and stored in a reel, but can also be retrieved by hand, with a fixed attachment to the end of a rod, or via a motor.

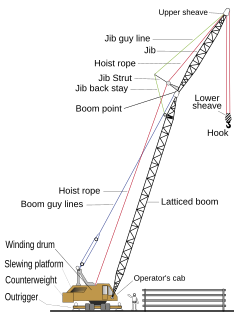

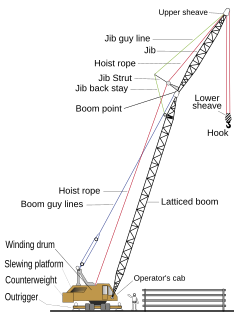

A crane is a type of machine, generally equipped with a hoist rope, wire ropes or chains, and sheaves, that can be used both to lift and lower materials and to move them horizontally. It is mainly used for lifting heavy objects and transporting them to other places. The device uses one or more simple machines to create mechanical advantage and thus move loads beyond the normal capability of a human. Cranes are commonly employed in transportation for the loading and unloading of freight, in construction for the movement of materials, and in manufacturing for the assembling of heavy equipment.

Cargo consists of bulk goods conveyed by water, air, or land. In economics, freight is cargo that is transported at a freight rate for commercial gain. Cargo was originally a shipload but now covers all types of freight, including transport by rail, van, truck, or intermodal container. The term cargo is also used in case of goods in the cold-chain, because the perishable inventory is always in transit towards a final end-use, even when it is held in cold storage or other similar climate-controlled facility. The term freight is commonly used to describe the movements of flows of goods being transported by any mode of transportation.

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket. It is a simple, reliable, and efficient means of power transmission.

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

A dump truck, known also as a dumping truck, dump trailer, dumper trailer, dump lorry or dumper lorry or a dumper for short, is used for transporting materials for construction as well as coal. A typical dump truck is equipped with an open-box bed, which is hinged at the rear and equipped with hydraulic rams to lift the front, allowing the material in the bed to be deposited ("dumped") on the ground behind the truck at the site of delivery. In the UK, Australia, South Africa and India the term applies to off-road construction plants only and the road vehicle is known as a tip lorry, tipper lorry, tipper truck, tip truck, tip trailer or tipper trailer or simply a tipper.

A coupling is a mechanism typically placed at each end of a railway vehicle that connects them together to form a train. A variety of coupler types have been developed over the course of railway history. Key issues in their design include strength, reliability, ease of making connections and operator safety.

Snow chains, or tire chains, are devices fitted to the tires of vehicles to provide increased traction when driving through snow and ice.

A windlass is a machine used on ships that is used to let-out and heave-up equipment such as a ship's anchor or a fishing trawl. On some ships, it may be located in a specific room called the windlass room.

Wire rope is several strands of metal wire twisted into a helix forming a composite rope, in a pattern known as laid rope. Larger diameter wire rope consists of multiple strands of such laid rope in a pattern known as cable laid.

A hoist is a device used for lifting or lowering a load by means of a drum or lift-wheel around which rope or chain wraps. It may be manually operated, electrically or pneumatically driven and may use chain, fiber or wire rope as its lifting medium. The most familiar form is an elevator, the car of which is raised and lowered by a hoist mechanism. Most hoists couple to their loads using a lifting hook. Today, there are a few governing bodies for the North American overhead hoist industry which include the Hoist Manufactures Institute, ASME, and the Occupational Safety and Health Administration. HMI is a product counsel of the Material Handling Industry of America consisting of hoist manufacturers promoting safe use of their products.

A lifting hook is a device for grabbing and lifting loads by means of a device such as a hoist or crane. A lifting hook is usually equipped with a safety latch to prevent the disengagement of the lifting wire rope sling, chain or rope to which the load is attached.

A chain is a serial assembly of connected pieces, called links, typically made of metal, with an overall character similar to that of a rope in that it is flexible and curved in compression but linear, rigid, and load-bearing in tension. A chain may consist of two or more links. Chains can be classified by their design, which can be dictated by their use:

Methods have been devised to modify the yield strength, ductility, and toughness of both crystalline and amorphous materials. These strengthening mechanisms give engineers the ability to tailor the mechanical properties of materials to suit a variety of different applications. For example, the favorable properties of steel result from interstitial incorporation of carbon into the iron lattice. Brass, a binary alloy of copper and zinc, has superior mechanical properties compared to its constituent metals due to solution strengthening. Work hardening has also been used for centuries by blacksmiths to introduce dislocations into materials, increasing their yield strengths.

Safe Working Load (SWL) sometimes stated as the Normal Working Load (NWL) is the maximum safe force that a piece of lifting equipment, lifting device or accessory can exert to lift, suspend, or lower, a given mass without fear of breaking. Usually marked on the equipment by the manufacturer. It is a calculation of the Minimum Breaking Strength (MBS) also known as Minimum Breaking Load (MBL) divided by a safety factor, usually ranging from 4 to 6 on lifting equipment. The factor can be as high as 10:1 or 10 to 1, if the equipment poses a risk to a person's life.

ASTM A325 is an ASTM International standard for heavy hex structural bolts, titled Standard Specification for Structural Bolts, Steel, Heat Treated, 120/105 ksi Minimum Tensile Strength. It defines mechanical properties for bolts that range from 1⁄2 to 1+1⁄2 inches in diameter.

Most of the terms listed in Wikipedia glossaries are already defined and explained within Wikipedia itself. However, glossaries like this one are useful for looking up, comparing and reviewing large numbers of terms together. You can help enhance this page by adding new terms or writing definitions for existing ones.

This glossary of structural engineering terms pertains specifically to structural engineering and its sub-disciplines. Please see glossary of engineering for a broad overview of the major concepts of engineering.

Green strength, or handling strength, can be defined as the strength of a material as it is processed to form its final ultimate tensile strength. This strength is usually considerably lower than the final ultimate strength of a material. The term green strength is usually referenced when discussing non-metallic materials such as adhesives and elastomers. Recently, it has also been referenced in metallurgy applications such as powdered metallurgy.