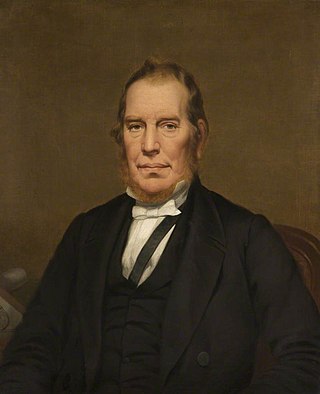

Sir Joseph Whitworth, 1st Baronet was an English engineer, entrepreneur, inventor and philanthropist. In 1841, he devised the British Standard Whitworth system, which created an accepted standard for screw threads. Whitworth also created the Whitworth rifle, often called the "sharpshooter" because of its accuracy, which is considered one of the earliest examples of a sniper rifle, used by some Confederate forces during the American Civil war.

A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

Jacques de Vaucanson was a French inventor and artist who built the first all-metal lathe. This invention was crucial for the Industrial Revolution. The lathe is known as the mother of machine tools, as it was the first machine tool that led to the invention of other machine tools. He was responsible for the creation of impressive and innovative automata. He also was the first person to design an automatic loom.

Guilloché, or guilloche, is a decorative technique in which a very precise, intricate and repetitive pattern is mechanically engraved into an underlying material via engine turning, which uses a machine of the same name. Engine turning machines may include the rose engine lathe and also the straight-line engine. This mechanical technique improved on more time-consuming designs achieved by hand and allowed for greater delicacy, precision, and closeness of line, as well as greater speed.

Richard Roberts was a Welsh patternmaker and engineer whose development of high-precision machine tools contributed to the birth of production engineering and mass production.

Woodturning is the craft of using a wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheel, the wood lathe is a mechanism that can generate a variety of forms. The operator is known as a turner, and the skills needed to use the tools were traditionally known as turnery. In pre-industrial England, these skills were sufficiently difficult to be known as "the mysteries of the turners' guild." The skills to use the tools by hand, without a fixed point of contact with the wood, distinguish woodturning and the wood lathe from the machinist's lathe, or metal-working lathe.

In woodworking and carpentry, a pair of winding sticks is a tool that aids in viewing twist in pieces of lumber by amplifying the defect. Winding sticks can be as simple as any two straight sticks or they can be elegant, decorated, dimensionally stable wood like mahogany. A pair of framing squares may also be suitable. Traditionally they are 16 inches (41 cm) to 30 inches (76 cm) long, 1+3⁄4 inches (44 mm) tall and tapered in their height from 3⁄8 inch (9.5 mm) to 1⁄8 inch (3.2 mm). The longer the winding sticks, the more they will amplify the wind. It is common for a woodworker to make a matching pair for the purpose, and contrasting colors of woods improve the discernability of differences in level between the two sticks as they are compared.

A rose engine lathe is a specialized kind of geometric lathe. The head stock rocks back and forth with a rocking motion and/or slides along the spindle axis in a pumping motion. A rosette or cam-like pattern mounted on the spindle is controlled by moving against a cam follower(s) while the lathe spindle rotates. Rose engine work can make flower patterns, as well as convoluted, symmetrical, multi-lobed geometric patterns. The patterns it produces are similar to that of a Spirograph, in metal. No other ornamental lathe can produce these "rose" patterns. The decoration produced by a rose engine lathe is called guilloche. It sometimes confused with "jewel finishes" or engine turning, a much cheaper process of making swirly marks in metal by a rotating abrasive peg or pad, which is repeatedly applied to the surface to make a pattern of overlapping circles. Jewel finishes used to be common on stereo faceplates and automobile interiors.

James Hartness was an American business executive, inventor, mechanical engineer, entrepreneur, amateur astronomer, and politician who served as the 58th governor of Vermont from 1921 to 1923.

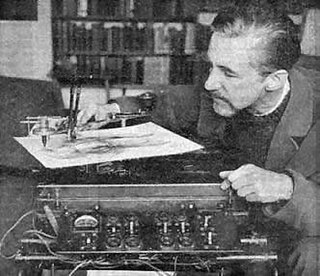

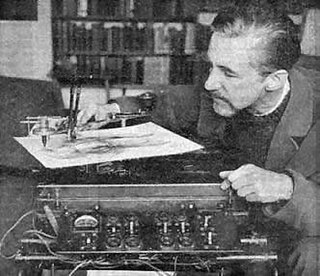

Desmond Paul Henry (1921–2004) was a Manchester University Lecturer and Reader in Philosophy (1949–82). He was one of the first British artists to experiment with machine-generated visual effects at the time of the emerging global computer art movement of the 1960s. During this period, Henry constructed a succession of three electro-mechanical drawing machines from modified bombsight analogue computers which were employed in World War II bombers to calculate the accurate release of bombs onto their targets. Henry's machine-generated effects resemble complex versions of the abstract, curvilinear graphics which accompany Microsoft's Windows Media Player. Henry's machine-generated effects may therefore also be said to represent early examples of computer graphics: "the making of line drawings with the aid of computers and drawing machines".

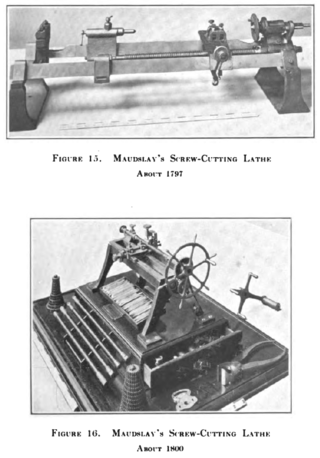

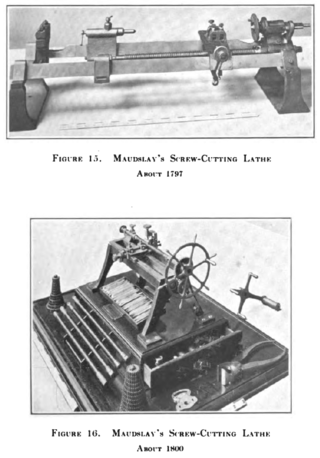

A screw-cutting lathe is a machine capable of cutting very accurate screw threads via single-point screw-cutting, which is the process of guiding the linear motion of the tool bit in a precisely known ratio to the rotating motion of the workpiece. This is accomplished by gearing the leadscrew to the spindle with a certain gear ratio for each thread pitch. Every degree of spindle rotation is matched by a certain distance of linear tool travel, depending on the desired thread pitch.

Edward Preston & Sons is a tool manufacturer based in Birmingham, England.

Ornamental turning is a type of turning, a craft that involves cutting of a work mounted in a lathe. The work can be made of any material that is suitable for being cut in this way, such as wood, bone, ivory or metal. Plain turning is work executed on a lathe where a transverse section through any part of the work comprises a plain circle. Ornamental turning, also called Complex turning, is executed on a lathe with attachments which convert that plain circular section to variants of outline; these range from a simple series of cuts taken at intervals around the work to non-circular movements whereby the whole of the circular shape is removed to give a completely different form. Such shapes are achieved by various means, the principal ones being:

The index of physics articles is split into multiple pages due to its size.

An iron founder in its more general sense is a worker in molten ferrous metal, generally working within an iron foundry. However, the term 'iron founder' is usually reserved for the owner or manager of an iron foundry, a person also known in Victorian England as a 'master'. Workers in a foundry are generically described as 'foundrymen'; however, the various craftsmen working in foundries, such as moulders and pattern makers, are often referred to by their specific trades.

John Adamson is a British publisher, translator and writer. He specialises in illustrated books in the fine and decorative arts.

The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide.

Charles Holtzapffel (1806-1847) was a mechanical engineer and technical writer and one of the Holtzapffel dynasty of tool and lathe makers. He wrote a five volume treatise called Turning and Mechanical Manipulation, which is considered a blueprint for ornamental turning, with over 3000 pages and 1600 illustrations.