Cavitation in fluid mechanics and engineering normally is the phenomenon in which the static pressure of a liquid reduces to below the liquid's vapor pressure, leading to the formation of small vapor-filled cavities in the liquid. When subjected to higher pressure, these cavities, called "bubbles" or "voids", collapse and can generate shock waves that may damage machinery. These shock waves are strong when they are very close to the imploded bubble, but rapidly weaken as they propagate away from the implosion. Cavitation is a significant cause of wear in some engineering contexts. Collapsing voids that implode near to a metal surface cause cyclic stress through repeated implosion. This results in surface fatigue of the metal, causing a type of wear also called "cavitation". The most common examples of this kind of wear are to pump impellers, and bends where a sudden change in the direction of liquid occurs.

A hydraulic ram pump, ram pump, or hydram is a cyclic water pump powered by hydropower. It takes in water at one "hydraulic head" (pressure) and flow rate, and outputs water at a higher hydraulic head and lower flow rate. The device uses the water hammer effect to develop pressure that allows a portion of the input water that powers the pump to be lifted to a point higher than where the water originally started. The hydraulic ram is sometimes used in remote areas, where there is both a source of low-head hydropower and a need for pumping water to a destination higher in elevation than the source. In this situation, the ram is often useful, since it requires no outside source of power other than the kinetic energy of flowing water.

A pump is a device that moves fluids, or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic or pneumatic energy.

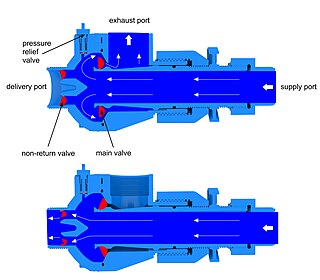

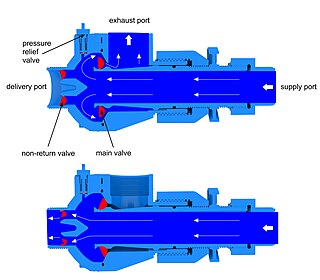

A valve is a device or natural object that regulates, directs or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin valva, the moving part of a door, in turn from volvere, to turn, roll.

Hydraulic shock is a pressure surge or wave caused when a fluid in motion is forced to stop or change direction suddenly: a momentum change. It is usually observed in a liquid but gases can also be affected. This phenomenon commonly occurs when a valve closes suddenly at an end of a pipeline system and a pressure wave propagates in the pipe.

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid to flow through it in only one direction.

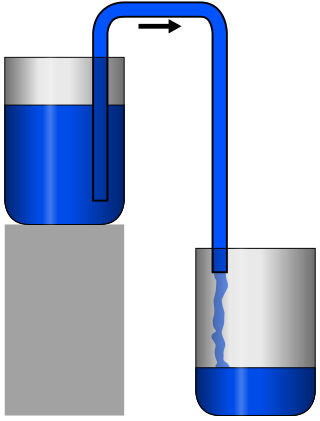

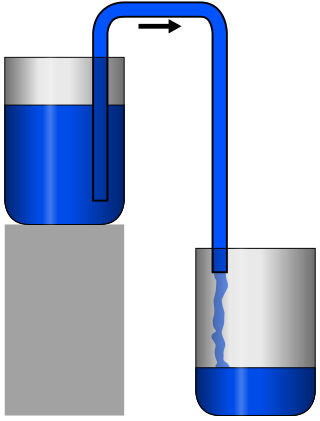

A siphon is any of a wide variety of devices that involve the flow of liquids through tubes. In a narrower sense, the word refers particularly to a tube in an inverted "U" shape, which causes a liquid to flow upward, above the surface of a reservoir, with no pump, but powered by the fall of the liquid as it flows down the tube under the pull of gravity, then discharging at a level lower than the surface of the reservoir from which it came.

Hydropneumatic suspension is a type of motor vehicle suspension system, invented by Paul Magès, produced by Citroën, and fitted to Citroën cars, as well as being used under licence by other car manufacturers. Similar systems are also widely used on modern tanks and other large military vehicles. The suspension was referred to as Suspension oléopneumatique in early literature, pointing to oil and air as its main components.

A hydraulic accumulator is a pressure storage reservoir in which an incompressible hydraulic fluid is held under pressure that is applied by an external source of mechanical energy. The external source can be an engine, a spring, a raised weight, or a compressed gas. An accumulator enables a hydraulic system to cope with extremes of demand using a less powerful pump, to respond more quickly to a temporary demand, and to smooth out pulsations. It is a type of energy storage device.

An air lock is a restriction of, or complete stoppage of liquid flow caused by vapour trapped in a high point of a liquid-filled pipe system. The gas, being less dense than the liquid, rises to any high points. This phenomenon is known as vapor lock, or air lock.

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes.

Electronic-hydraulic analogies are the representation of electronic circuits by hydraulic circuits. Since electric current is invisible and the processes in play in electronics are often difficult to demonstrate, the various electronic components are represented by hydraulic equivalents. Electricity was originally understood to be a kind of fluid, and the names of certain electric quantities are derived from hydraulic equivalents.

Hydronics is the use of liquid water or gaseous water (steam) or a water solution as a heat-transfer medium in heating and cooling systems. The name differentiates such systems from oil and refrigerant systems.

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits.

The term separator in oilfield terminology designates a pressure vessel used for separating well fluids produced from oil and gas wells into gaseous and liquid components. A separator for petroleum production is a large vessel designed to separate production fluids into their constituent components of oil, gas and water. A separating vessel may be referred to in the following ways: Oil and gas separator, Separator, Stage separator, Trap, Knockout vessel, Flash chamber, Expansion separator or expansion vessel, Scrubber, Filter. These separating vessels are normally used on a producing lease or platform near the wellhead, manifold, or tank battery to separate fluids produced from oil and gas wells into oil and gas or liquid and gas. An oil and gas separator generally includes the following essential components and features:

- A vessel that includes (a) primary separation device and/or section, (b) secondary "gravity" settling (separating) section, (c) mist extractor to remove small liquid particles from the gas, (d) gas outlet, (e) liquid settling (separating) section to remove gas or vapor from oil, (f) oil outlet, and (g) water outlet.

- Adequate volumetric liquid capacity to handle liquid surges (slugs) from the wells and/or flowlines.

- Adequate vessel diameter and height or length to allow most of the liquid to separate from the gas so that the mist extractor will not be flooded.

- A means of controlling an oil level in the separator, which usually includes a liquid-level controller and a diaphragm motor valve on the oil outlet.

- A back pressure valve on the gas outlet to maintain a steady pressure in the vessel.

- Pressure relief devices.

An expansion tank or expansion vessel is a small tank used to protect closed water heating systems and domestic hot water systems from excessive pressure. The tank is partially filled with air, whose compressibility cushions shock caused by water hammer and absorbs excess water pressure caused by thermal expansion.

A surge tank is a standpipe or storage reservoir at the downstream end of a closed aqueduct, feeder pipe, or dam to absorb sudden rises of pressure, as well as to quickly provide extra water during a brief drop in pressure.

Surge control is the use of different techniques and equipment in a hydraulic system to prevent any excessive gain in pressure that would cause the hydraulic process pressure to exceed the maximum working pressure of the mechanical equipment used in the system.

A pipe support or pipe hanger is a designed element that transfer the load from a pipe to the supporting structures. The load includes the weight of the pipe proper, the content that the pipe carries, all the pipe fittings attached to pipe, and the pipe covering such as insulation. The four main functions of a pipe support are to anchor, guide, absorb shock, and support a specified load. Pipe supports used in high or low temperature applications may contain insulation materials. The overall design configuration of a pipe support assembly is dependent on the loading and operating conditions.

An anti-dribble valve is a component of a fuel injection system used for diesel engines. Its main function is to provide precise timing of fuel injection, particularly at the end of the injection time. If fuel was allowed to 'dribble' after the main phase of injection, this fuel would be too late for good combustion and so would be only partially burned as visible exhaust soot.