Hydroskimming is one of the simplest types of refinery used in the petroleum industry [1] and still represents a large proportion of refining facilities, particularly in developing countries. [2] A hydroskimming refinery is defined as a refinery equipped with atmospheric distillation, naphtha reforming and necessary treating processes. [3] A hydroskimming refinery is therefore more complex than a topping refinery (which just separates the crude into its constituent petroleum products by distillation, known as atmospheric distillation, and produces naphtha but no gasoline) and it produces gasoline. The addition of catalytic reformer enables a hydroskimming refinery to generate higher octane reformate; benzene, toluene, and xylene; and hydrogen for hydrotreating units. [4] However, a hydroskimming refinery produces a surplus of fuel oil with a relatively unattractive price and demand. [3]

Most refineries, therefore, add vacuum distillation and catalytic cracking, which adds one more level of complexity by reducing fuel oil by conversion to light distillates and middle distillates. A coking refinery adds further complexity to the cracking refinery by high conversion of fuel oil into distillates and petroleum coke.

Catalytic cracking, coking and other such conversion units are referred to as secondary processing units. The Nelson Complexity Index, captures the proportion of the secondary conversion unit capacities relative to the primary distillation or topping capacity. The Nelson Complexity Index typically varies from about 2 for hydroskimming refineries, to about 5 for the Cracking refineries and over 9 for the Coking refineries. [5]

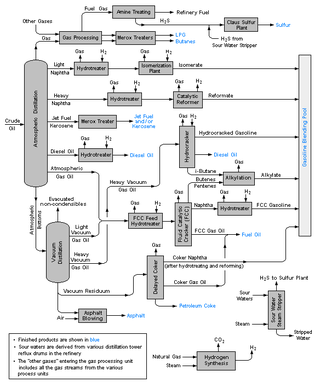

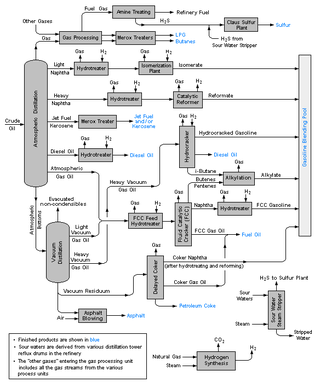

An oil refinery or petroleum refinery is an industrial process plant where petroleum is transformed and refined into products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liquefied petroleum gas and petroleum naphtha. Petrochemical feedstock like ethylene and propylene can also be produced directly by cracking crude oil without the need of using refined products of crude oil such as naphtha. The crude oil feedstock has typically been processed by an oil production plant. There is usually an oil depot at or near an oil refinery for the storage of incoming crude oil feedstock as well as bulk liquid products. In 2020, the total capacity of global refineries for crude oil was about 101.2 million barrels per day.

In petrochemistry, petroleum geology and organic chemistry, cracking is the process whereby complex organic molecules such as kerogens or long-chain hydrocarbons are broken down into simpler molecules such as light hydrocarbons, by the breaking of carbon–carbon bonds in the precursors. The rate of cracking and the end products are strongly dependent on the temperature and presence of catalysts. Cracking is the breakdown of large hydrocarbons into smaller, more useful alkanes and alkenes. Simply put, hydrocarbon cracking is the process of breaking long-chain hydrocarbons into short ones. This process requires high temperatures.

A visbreaker is a processing unit in an oil refinery whose purpose is to reduce the quantity of residual oil produced in the distillation of crude oil and to increase the yield of more valuable middle distillates by the refinery. A visbreaker thermally cracks large hydrocarbon molecules in the oil by heating in a furnace to reduce its viscosity and to produce small quantities of light hydrocarbons.. The process name of "visbreaker" refers to the fact that the process reduces the viscosity of the residual oil. The process is non-catalytic.

Catalytic reforming is a chemical process used to convert petroleum refinery naphthas distilled from crude oil into high-octane liquid products called reformates, which are premium blending stocks for high-octane gasoline. The process converts low-octane linear hydrocarbons (paraffins) into branched alkanes (isoparaffins) and cyclic naphthenes, which are then partially dehydrogenated to produce high-octane aromatic hydrocarbons. The dehydrogenation also produces significant amounts of byproduct hydrogen gas, which is fed into other refinery processes such as hydrocracking. A side reaction is hydrogenolysis, which produces light hydrocarbons of lower value, such as methane, ethane, propane and butanes.

Fluid catalytic cracking (FCC) is the conversion process used in petroleum refineries to convert the high-boiling point, high-molecular weight hydrocarbon fractions of petroleum into gasoline, alkene gases, and other petroleum products. The cracking of petroleum hydrocarbons was originally done by thermal cracking, now virtually replaced by catalytic cracking, which yields greater volumes of high octane rating gasoline; and produces by-product gases, with more carbon-carbon double bonds, that are of greater economic value than the gases produced by thermal cracking.

Guwahati Refinery was set up at Noonmati in Guwahati on 1 January 1962. Guwahati Refinery is the first Public Sector refinery of India and belongs to Indian Oil Corporation Limited. The refinery was inaugurated by Late Pandit Jawahar Lal Nehru, the first Prime Minister of independent India. The refinery was built with Romanian Collaboration and has a capacity of 1.0 million metric tonnes per annum. This refinery process crude oil from Upper Assam Oil Fields, India and helps cater energy need of the region. Major Products of this refinery are

- LPG,

- Motor Spirit (Petrol),

- Aviation Turbine Fuel (ATF),

- Kerosene,

- High Speed Diesel,

- Light Diesel Oil and

- Raw Petroleum Coke.

The Gujarat Refinery is an oil refinery located at Koyali, Vadodara District in Gujarat, Western India. It is the third largest refinery owned by Indian Oil Corporation after Paradip and Panipat Refinery. The refinery is currently under projected expansion to 18 million tonnes per year.

The Nelson complexity index (NCI) is a measure to compare the secondary conversion capacity of a petroleum refinery with the primary distillation capacity. The index provides an easy metric for quantifying and ranking the complexity of various refineries and units. To calculate the index, it is necessary to use complexity factors, which compare the cost of upgrading units to the cost of crude distillation unit.

Shell Haven was a port on the north bank of the Thames Estuary at the eastern end of Thurrock, Essex, England and then an oil refinery. The refinery closed in 1999 and the site was purchased by DP World who received planning consent in May 2007 for the new London Gateway deep water container port at the site. The neighbouring Coryton Refinery remained in operation until 2012.

Gdańsk oil refinery is a 10.5 million tonne per year refinery located near the Polish city of Gdańsk on the Baltic Sea. The refinery was established in 1975 to supply fuels and lubricants, and has undergone several upgrades and expansions to increase its capacity and the range of products available. It now has a Nelson complexity index of 11.1. It is one of two oil refineries in Poland, the other is Plock refinery.

Corinth Refinery is an oil refining complex in Greece, the largest industrial complex in the country with a capacity of 380,000 barrels per day (60,000 m3/d), and it is operated by Motor Oil Hellas.

The Aspropyrgos Refinery is an oil refining complex located near Aspropyrgos, a suburb of Athens, in Greece. It is operated by Hellenic Petroleum. The refinery has a nominal annual refining capacity of 7.5 million tons.

The BPRefinery (Kent) was an oil refinery on the Isle of Grain in Kent. It was commissioned in 1953 and had a maximum processing capacity of 11 million tonnes of crude oil per year. It was decommissioned in August 1982.

The Montreal East Refinery was an oil refinery located in Montreal East and formerly Shell Canada's largest refinery. In October 2010, refinery operations permanently ceased and the facility was subsequently converted into a storage terminal.

Petroleum refining processes are the chemical engineering processes and other facilities used in petroleum refineries to transform crude oil into useful products such as liquefied petroleum gas (LPG), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils.

Petroleum naphtha is an intermediate hydrocarbon liquid stream derived from the refining of crude oil with CAS-no 64742-48-9. It is most usually desulfurized and then catalytically reformed, which rearranges or restructures the hydrocarbon molecules in the naphtha as well as breaking some of the molecules into smaller molecules to produce a high-octane component of gasoline.

The Port Harcourt Refining Company,, is a Nigeria-based oil and gas company primarily specializing in the refining of crude oil into petroleum products. It is headquartered in Port Harcourt metropolitan area of Rivers State, southeastern Nigeria. The company is a subsidiary of the Nigerian National Petroleum Corporation (NNPC).

The Ruwais Refinery is operated by the Abu Dhabi National Oil Company (ADNOC). The complex can process up to 837,000 barrels of crude oil and condensate per day, making it the fourth-largest single-site oil refinery in the world and the biggest in the Middle East. The refinery is situated in the city of Ruwais, in Abu Dhabi’s western region. It is highly integrated with ADNOC’s other plants in the Ruwais industrial area – such as the Borouge 3 petrochemical plant.

The Heydar Aliyev Baku Oil Refinery is an oil refinery located in Baku, Azerbaijan. It is currently the only oil refinery in Azerbaijan, capable of producing about 120,000 barrels (19,000 m3) of refined products per day. The refinery meets the entire domestic demand for petroleum products and exports more than 40% of the products. The plant processes 15 different products including gasoline, diesel, jet fuel, black oil, petroleum coke, asphalt, lubricants etc. It is owned and operated by SOCAR, which is the national oil company of the Azerbaijan Republic.

The Dangote Refinery is an oil refinery owned by Dangote Group that was inaugurated on 22 May 2023 in Lekki, Nigeria. When fully operational, it is expected to have the capacity to process about 650,000 barrels of crude oil per day, making it the largest single-train refinery in the world. The investment is over US$19 billion.