Related Research Articles

In physics, cryogenics is the production and behaviour of materials at very low temperatures.

Ice cream is a frozen dessert typically made from milk or cream that has been flavoured with a sweetener, either sugar or an alternative, and a spice, such as cocoa or vanilla, or with fruit, such as strawberries or peaches. Food colouring is sometimes added in addition to stabilizers. The mixture is cooled below the freezing point of water and stirred to incorporate air spaces and prevent detectable ice crystals from forming. It can also be made by whisking a flavoured cream base and liquid nitrogen together. The result is a smooth, semi-solid foam that is solid at very low temperatures. It becomes more malleable as its temperature increases.

Cryobiology is the branch of biology that studies the effects of low temperatures on living things within Earth's cryosphere or in science. The word cryobiology is derived from the Greek words κρῧος [kryos], "cold", βίος [bios], "life", and λόγος [logos], "word". In practice, cryobiology is the study of biological material or systems at temperatures below normal. Materials or systems studied may include proteins, cells, tissues, organs, or whole organisms. Temperatures may range from moderately hypothermic conditions to cryogenic temperatures.

Liquid nitrogen (LN2) is nitrogen in a liquid state at low temperature. Liquid nitrogen has a boiling point of about −196 °C (−321 °F; 77 K). It is produced industrially by fractional distillation of liquid air. It is a colorless, mobile liquid whose viscosity is about one-tenth that of acetone (i.e. roughly one-thirtieth that of water at room temperature). Liquid nitrogen is widely used as a coolant.

Freezing food preserves it from the time it is prepared to the time it is eaten. Since early times, farmers, fishermen, and trappers have preserved grains and produce in unheated buildings during the winter season. Freezing food slows decomposition by turning residual moisture into ice, inhibiting the growth of most bacterial species. In the food commodity industry, there are two processes: mechanical and cryogenic. The freezing kinetics is important to preserve the food quality and texture. Quicker freezing generates smaller ice crystals and maintains cellular structure. Cryogenic freezing is the quickest freezing technology available due to the ultra low liquid nitrogen temperature −196 °C (−320 °F).

A frozen meal, prepackaged meal, ready-made meal, ready meal (UK), frozen dinner, and microwave meal is ultra-processed food portioned for an individual. A frozen meal in the United States and Canada usually consists of a type of meat, fish, or pasta for the main course, and sometimes vegetables, potatoes, and/or a dessert. Some frozen meals feature Indian, Chinese, Mexican, and other foods of international customs. Another form of convenience food, which is merely a refrigerated ready meal that requires less heating but expires sooner, is popular.

In physics and chemistry, flash freezing is the process whereby objects are rapidly frozen. This is done by subjecting them to cryogenic temperatures, or it can be done through direct contact with liquid nitrogen at −196 °C (−320.8 °F). It is commonly used in the food industry.

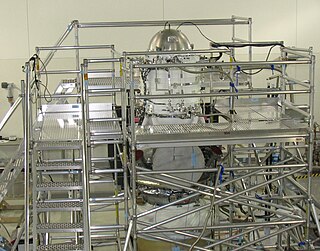

A cryostat is a device used to maintain low cryogenic temperatures of samples or devices mounted within the cryostat. Low temperatures may be maintained within a cryostat by using various refrigeration methods, most commonly using cryogenic fluid bath such as liquid helium. Hence it is usually assembled into a vessel, similar in construction to a vacuum flask or Dewar. Cryostats have numerous applications within science, engineering, and medicine.

Freeze drying, also known as lyophilization or cryodesiccation, is a low temperature dehydration process that involves freezing the product and lowering pressure, thereby removing the ice by sublimation. This is in contrast to dehydration by most conventional methods that evaporate water using heat.

A refrigerator, commonly fridge, is a commercial and home appliance consisting of a thermally insulated compartment and a heat pump that transfers heat from its inside to its external environment so that its inside is cooled to a temperature below the room temperature. Refrigeration is an essential food storage technique around the world. The low temperature reduces the reproduction rate of bacteria, so the refrigerator lowers the rate of spoilage. A refrigerator maintains a temperature a few degrees above the freezing point of water. The optimal temperature range for perishable food storage is 3 to 5 °C. A freezer is a specialized refrigerator, or portion of a refrigerator, that maintains its contents’ temperature below the freezing point of water. The refrigerator replaced the icebox, which had been a common household appliance for almost a century and a half. The United States Food and Drug Administration recommends that the refrigerator be kept at or below 4 °C (40 °F) and that the freezer be regulated at −18 °C (0 °F).

Clarence Birdseye was an American inventor, entrepreneur, and naturalist, considered the founder of the modern frozen food industry. He founded the frozen food company Birds Eye. Among his inventions during his career was the double belt freezer.

Dippin' Dots is an ice cream snack invented by Curt Jones in 1988. The confection is created by flash freezing ice cream mix in liquid nitrogen. The snack is made by Dippin' Dots, Inc., headquartered in Paducah, Kentucky. Dippin' Dots are sold in 14 countries, including Honduras and Luxembourg.

Auto-defrost, automatic defrost or self-defrosting is a technique which regularly defrosts the evaporator in a refrigerator or freezer. Appliances using this technique are often called frost free, frostless, or no-frost.

A fluidized bed is a physical phenomenon that occurs when a solid particulate substance is under the right conditions so that it behaves like a fluid. The usual way to achieve a fluidized bed is to pump pressurized fluid into the particles. The resulting medium then has many properties and characteristics of normal fluids, such as the ability to free-flow under gravity, or to be pumped using fluid technologies.

Vacuum packing is a method of packaging that removes air from the package prior to sealing. This method involves placing items in a plastic film package, removing air from inside and sealing the package. Shrink film is sometimes used to have a tight fit to the contents. The intent of vacuum packing is usually to remove oxygen from the container to extend the shelf life of foods and, with flexible package forms, to reduce the volume of the contents and package.

The term fish processing refers to the processes associated with fish and fish products between the time fish are caught or harvested, and the time the final product is delivered to the customer. Although the term refers specifically to fish, in practice it is extended to cover any aquatic organisms harvested for commercial purposes, whether caught in wild fisheries or harvested from aquaculture or fish farming.

Cryopreservation or cryoconservation is a process where biological material - cells, tissues, or organs - are frozen to preserve the material for an extended period of time. At low temperatures any cell metabolism which might cause damage to the biological material in question is effectively stopped. Cryopreservation is an effective way to transport biological samples over long distances, store samples for prolonged periods of time, and create a bank of samples for users. Molecules, referred to as cryoprotective agents (CPAs), are added to reduce the osmotic shock and physical stresses cells undergo in the freezing process. Some cryoprotective agents used in research are inspired by plants and animals in nature that have unique cold tolerance to survive harsh winters, including: trees, wood frogs, and tardigrades.The first human corpse to be frozen with the hope of future resurrection was James Bedford's, a few hours after his cancer-caused death in 1967.[15] Bedford's is the only cryonics corpse frozen before 1974 still frozen today.

A liquid nitrogen engine is powered by liquid nitrogen, which is stored in a tank. Traditional nitrogen engine designs work by heating the liquid nitrogen in a heat exchanger, extracting heat from the ambient air and using the resulting pressurized gas to operate a piston or rotary motor. Vehicles propelled by liquid nitrogen have been demonstrated, but are not used commercially. One such vehicle, Liquid Air, was demonstrated in 1902.

Pumpable icetechnology (PIT) uses thin liquids, with the cooling capacity of ice. Pumpable ice is typically a slurry of ice crystals or particles ranging from 5 micrometers to 1 cm in diameter and transported in brine, seawater, food liquid, or gas bubbles of air, ozone, or carbon dioxide.

Ground freezing is a construction technique used in circumstances where soil needs to be stabilized so it will not collapse next to excavations, or to prevent contaminants spilled into soil from being leached away. Ground freezing has been used for at least one hundred years.

References

- ↑ Alfaro, Danilo. "IQF (Individually Quick Frozen)" Archived 2016-11-24 at the Wayback Machine , Culinary Arts . August 26, 2016 Retrieved on July 28, 2016.

- ↑ Editors of Encyclopædia Britannica "Individually quick-frozen method", Encyclopædia Britannica . Retrieved on July 28, 2016.

- ↑ Pruthi, J. S. (1995). "Quick Freezing Preservation of Foods: Foods of animal origin", p. 14. Allied Publishers Limited. ISBN 81-7023-962-1.

- 1 2 Heldman, Dennis R. Hartel, Richard W (1997). "Principles of Food Processing", p. 123. Food Science Texts Series. ISBN 978-0-8342-1269-5.

- 1 2 Peterson, Randy "Cryogenic vs. Mechanical Freezers: The Best Uses for Each Method", Stellar Food For Thought. February 18, 2016. Retrieved on July 21, 2016.