Masonry is the craft of building a structure with brick, stone, or similar material, including mortar plastering which are often laid in, bound, and pasted together by mortar. The term masonry can also refer to the building units themselves.

A wall is a structure and a surface that defines an area; carries a load; provides security, shelter, or soundproofing; or, is decorative. There are many kinds of walls, including:

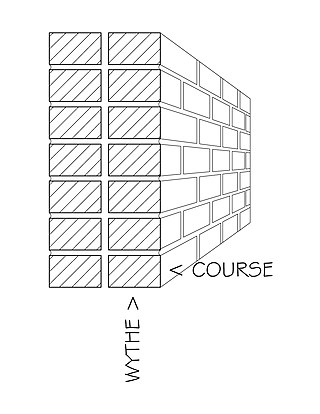

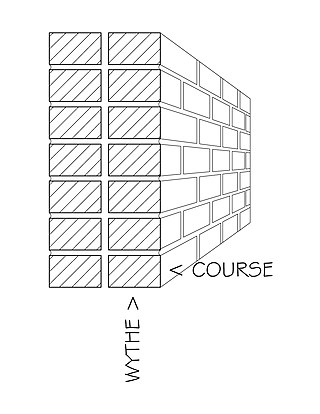

A wythe is a continuous vertical section of masonry one unit in thickness. A wythe may be independent of, or interlocked with, the adjoining wythe(s). A single wythe of brick that is not structural in nature is referred to as a masonry veneer.

A curtain wall is an exterior covering of a building in which the outer walls are non-structural, instead serving to protect the interior of the building from the elements. Because the curtain wall façade carries no structural load beyond its own dead load weight, it can be made of lightweight materials. The wall transfers lateral wind loads upon it to the main building structure through connections at floors or columns of the building.

Seismic retrofitting is the modification of existing structures to make them more resistant to seismic activity, ground motion, or soil failure due to earthquakes. With better understanding of seismic demand on structures and with recent experiences with large earthquakes near urban centers, the need of seismic retrofitting is well acknowledged. Prior to the introduction of modern seismic codes in the late 1960s for developed countries and late 1970s for many other parts of the world, many structures were designed without adequate detailing and reinforcement for seismic protection. In view of the imminent problem, various research work has been carried out. State-of-the-art technical guidelines for seismic assessment, retrofit and rehabilitation have been published around the world – such as the ASCE-SEI 41 and the New Zealand Society for Earthquake Engineering (NZSEE)'s guidelines. These codes must be regularly updated; the 1994 Northridge earthquake brought to light the brittleness of welded steel frames, for example.

A concrete block, also known as a cinder block in North American English, breeze block in British English, concrete masonry unit (CMU), or by various other terms, is a standard-size rectangular block used in building construction. The use of blockwork allows structures to be built in the traditional masonry style with layers of staggered blocks.

Natural building or ecological building is a discipline within the more comprehensive scope of green building, sustainable architecture as well as sustainable and ecological design that promotes the construction of buildings using sustainable processes and locally available natural materials.

Insulating concrete form or insulated concrete form (ICF) is a system of formwork for reinforced concrete usually made with a rigid thermal insulation that stays in place as a permanent interior and exterior substrate for walls, floors, and roofs. The forms are interlocking modular units that are dry-stacked and filled with concrete. The units lock together somewhat like Lego bricks and create a form for the structural walls or floors of a building. ICF construction has become commonplace for both low rise commercial and high performance residential construction as more stringent energy efficiency and natural disaster resistant building codes are adopted.

Framing, in construction, is the fitting together of pieces to give a structure support and shape. Framing materials are usually wood, engineered wood, or structural steel. The alternative to framed construction is generally called mass wall construction, where horizontal layers of stacked materials such as log building, masonry, rammed earth, adobe, etc. are used without framing.

A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete. Steel-reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, while thinner mud slabs may be used for exterior paving.

Earthquake engineering is an interdisciplinary branch of engineering that designs and analyzes structures, such as buildings and bridges, with earthquakes in mind. Its overall goal is to make such structures more resistant to earthquakes. An earthquake engineer aims to construct structures that will not be damaged in minor shaking and will avoid serious damage or collapse in a major earthquake. A properly engineered structure does not necessarily have to be extremely strong or expensive. It has to be properly designed to withstand the seismic effects while sustaining an acceptable level of damage.

Steel frame is a building technique with a "skeleton frame" of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame. The development of this technique made the construction of the skyscraper possible. Steel frame has displaced its predecessor, the iron frame, in the early 20th century.

A cavity wall is a type of wall that has an airspace between the outer face and the inner, usually structural, construction. The skins typically are masonry, such as brick or cinder block. Masonry is an absorbent material that can retain rainwater or condensation. One function of the cavity is to drain water through weep holes at the base of the wall system or above windows. The weep holes provide a drainage path through the cavity that allows accumulated water an outlet to the exterior of the structure. Usually, weep holes are created by leaving out mortar at the vertical joints between bricks at regular intervals, by the insertion of tubes, or by inserting an absorbent wicking material into the joint. Weep holes are placed wherever a cavity is interrupted by a horizontal element, such as door or window lintels, masonry bearing angles, or slabs. A cavity wall with masonry as both inner and outer vertical elements is more commonly referred to as a double wythe masonry wall.

Masonry veneer walls consist of a single non-structural external layer of masonry, typically made of brick, stone or manufactured stone. Masonry veneer can have an air space behind it and is technically called "anchored veneer". A masonry veneer attached directly to the backing is called "adhered veneer". The innermost element is structural, and may consist of masonry, concrete, timber or metal frame.

A steel plate shear wall (SPSW) consists of steel infill plates bounded by boundary elements.

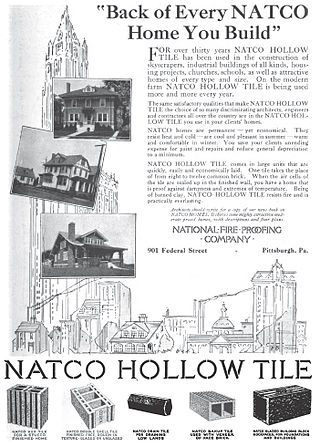

Structural clay tile describes a category of burned-clay building materials used to construct roofing, walls, and flooring for structural and non-structural purposes, especially in fireproofing applications. Also called building tile, structural terra cotta, hollow tile, saltillo tile, and clay block, the material is an extruded clay shape with substantial depth that allows it to be laid in the same manner as other clay or concrete masonry. In North America it was chiefly used during the late 19th and early 20th centuries, reaching peak popularity at the turn of the century and declining around the 1950s. Structural clay tile grew in popularity in the end of the nineteenth-century because it could be constructed faster, was lighter, and required simpler flat falsework than earlier brick vaulting construction.

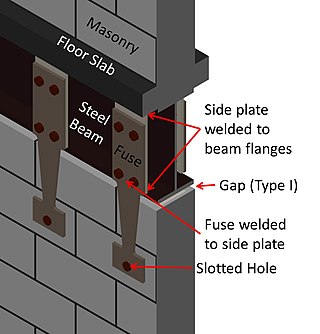

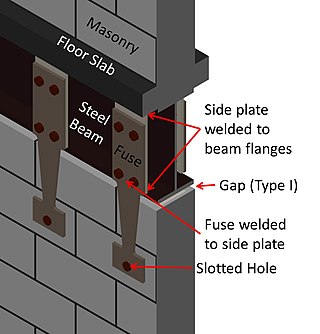

Hybrid masonry is a new type of building system that uses engineered, reinforced masonry to brace frame structures. Typically, hybrid masonry is implemented with concrete masonry panels used to brace steel frame structures. The basic concept is to attach a reinforced concrete masonry panel to a structural steel frame such that some combination of gravity forces, story shears and overturning moments can be transferred to the masonry. The structural engineer can choose from three different types of hybrid masonry and two different reinforcement anchorage types. In conventional steel frame building systems, the vertical force resisting steel frame system is supported in the lateral direction by steel bracing or an equivalent system. When the architectural plans call for concrete masonry walls to be placed within the frame, extra labor is required to ensure the masonry fits around the steel frame. Usually, this placement does not take advantage of the structural properties of the masonry panels. In hybrid masonry, the masonry panels take the place of conventional steel bracing, utilizing the structural properties of reinforced concrete masonry walls.

A windpost is a structural item used in the design and construction of masonry walls to increase lateral wall stability and protect them against damage from horizontal forces imposed by wind pressure, crowd or handrail loads. They are normally constructed from mild steel channel sections, supported at the head and the foot between floor slab levels and/or the principal steelwork sections forming the structural frame of the building. In cavity walls, the windpost will typically be fixed into the inner and outer leafs of the wall by specialist fixings and fastenings at regular intervals along its length. The windposts will be spaced along the walls of the building at regular intervals as calculated by the engineer to suit the required loadings.

This glossary of structural engineering terms pertains specifically to structural engineering and its sub-disciplines. Please see glossary of engineering for a broad overview of the major concepts of engineering.

Textile-reinforced mortars (TRM) (also known as fabric-reinforced cementitious mortars are composite materials used in structural strengthening of existing buildings, most notably in seismic retrofitting. The material consists of bidirectional orthogonal textiles made from knitted, woven or simply stitched rovings of high-strength fibres, embedded in inorganic matrices. The textiles can also be made from natural fibres, e.g. hemp or flax.