Related Research Articles

Mass production, also known as flow production, series production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch production, it is one of the three main production methods.

Samuel Colt was an American inventor, industrialist, and businessman who established Colt's Patent Fire-Arms Manufacturing Company and made the mass production of revolvers commercially viable.

Samuel Slater was an early English-American industrialist known as the "Father of the American Industrial Revolution", a phrase coined by Andrew Jackson, and the "Father of the American Factory System". In the United Kingdom, he was called "Slater the Traitor" and "Sam the Slate" because he brought British textile technology to the United States, modifying it for American use. He memorized the textile factory machinery designs as an apprentice to a pioneer in the British industry before migrating to the U.S. at the age of 21.

The American system of manufacturing was a set of manufacturing methods that evolved in the 19th century. The two notable features were the extensive use of interchangeable parts and mechanization for production, which resulted in more efficient use of labor compared to hand methods. The system was also known as armory practice because it was first fully developed in armories, namely, the United States Armories at Springfield in Massachusetts and Harpers Ferry in Virginia, inside contractors to supply the United States Armed Forces, and various private armories. The name "American system" came not from any aspect of the system that is unique to the American national character, but simply from the fact that for a time in the 19th century it was strongly associated with the American companies who first successfully implemented it, and how their methods contrasted with those of British and continental European companies. In the 1850s, the "American system" was contrasted to the British factory system which had evolved over the previous century. Within a few decades, manufacturing technology had evolved further, and the ideas behind the "American" system were in use worldwide. Therefore, in manufacturing today, which is global in the scope of its methods, there is no longer any such distinction.

Colt's Manufacturing Company, LLC is an American firearms manufacturer, founded in 1855 by Samuel Colt and now a subsidiary of Czech holding company Colt CZ Group. It is the successor corporation to Colt's earlier firearms-making efforts, which started in 1836. Colt is known for the engineering, production, and marketing of firearms, most especially between the 1850s and World War I, when it was a dominating force in its industry and a seminal influence on manufacturing technology. Colt's earliest designs played a major role in the popularization of the revolver and the shift away from single-shot pistols. Although Samuel Colt did not invent the revolver concept, his designs resulted in the first very successful model.

Deere & Company, doing business as John Deere, is an American corporation that manufactures agricultural machinery, heavy equipment, forestry machinery, diesel engines, drivetrains used in heavy equipment, and lawn care equipment. It also provides financial services and other related activities.

The Springfield Armory, more formally known as the United States Armory and Arsenal at Springfield located in the city of Springfield, Massachusetts, was the primary center for the manufacture of United States military firearms from 1777 until its closing in 1968. It was the first federal armory and one of the first factories in the United States dedicated to the manufacture of weapons. The site is preserved as the Springfield Armory National Historic Site, Western Massachusetts' only unit of the national park system. It features the world's largest collection of historic American firearms.

The putting-out system is a means of subcontracting work, like a tailor. Historically, it was also known as the workshop system and the domestic system. In putting-out, work is contracted by a central agent to subcontractors who complete the project via remote work. It was used in the English and American textile industries, in shoemaking, lock-making trades, and making parts for small firearms from the Industrial Revolution until the mid-19th century. After the invention of the sewing machine in 1846, the system lingered on for the making of ready-made men's clothing.

EbenSumner Draper was an American businessman and politician from Massachusetts. He was for many years a leading figure in what later became the Draper Corporation, the dominant manufacturer of cotton textile process machinery in the world during the late 19th and early 20th centuries. He served as the 44th governor of Massachusetts from 1909 to 1911.

The American system of watch manufacturing is a set of manufacturing techniques and best-practices to be used in the manufacture of watches and timepieces. It is derived from the American system of manufacturing techniques, a set of general techniques and guidelines for manufacturing that was developed in the 19th century. The system calls for using interchangeable parts, which is made possible by a strict system of organization, the extensive use of the machine shop, and quality control systems utilizing gauges to ensure precise and uniform dimensions. It was developed by Aaron Lufkin Dennison, a watch repairman who was inspired by the manufacturing techniques of the United States Armory at Springfield, Massachusetts, which manufactured identical parts, allowing rapid assembly of the final products. He proposed using similar techniques for the manufacture of watches. Before the American system of watch manufacturing was developed, watchmaking was primarily a European business. It involved making certain parts under the roof of a factory while obtaining other parts from piece workers who used their own cottages as workshops.

Interchangeable parts are parts that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into any assembly of the same type. One such part can freely replace another, without any custom fitting, such as filing. This interchangeability allows easy assembly of new devices, and easier repair of existing devices, while minimizing both the time and skill required of the person doing the assembly or repair.

A contract manufacturer (CM) is a manufacturer that contracts with a firm for components or products. It is a form of outsourcing. A contract manufacturer performing packaging operations is called copacker or a contract packager. Brand name companies focus on product innovation, design and sales, while the manufacturing takes place in independent factories.

Alpha Industries is an American clothing manufacturer founded in 1959 in Knoxville, Tennessee. Alpha Industries specializes in American military style and fashion apparel items such as flight jackets. It has produced the M65 Jacket for the US military for over half a century.

The American Precision Museum is located in the renovated 1846 Robbins & Lawrence factory on South Main Street in Windsor, Vermont. The building is said to be the first U.S. factory at which precision interchangeable parts were made, giving birth to the precision machine tool industry. In recognition of this history, the building was declared a National Historic Landmark in 1966. In 1987, the building was recognized by the American Society of Mechanical Engineers as an International Heritage Site, and the collection was recognized as an International Heritage Collection. For each of these designations, the armory was considered a site where pivotal events occurred in the history of American industry, as well as a place that lends itself to comprehensive interpretation of that history.

The history of Connecticut Industry is a major part of the history of Connecticut. Between the birth of the U.S. patent system in 1790 and 1930, Connecticut had more patents issued per capita than any other state; in the 19th century, when the U.S. as a whole was issued one patent per three thousand population, Connecticut inventors were issued one patent for every 700–1000 residents. Connecticut's first recorded invention was a lapidary machine, by Abel Buell of Killingworth, in 1765.

The Harpers Ferry Armory, more formally known as the United States Armory and Arsenal at Harpers Ferry, was the second federal armory created by the United States government; the first was the Springfield Armory. It was located in Harpers Ferry, Virginia, which since 1863 has been part of West Virginia. It was both an arsenal, manufacturing firearms, and an armory, a storehouse for firearms. Along with the Springfield Armory, it was instrumental in the development of machining techniques to make interchangeable parts of precisely the same dimensions.

Apple Inc. manufactures most of its products in China through partners like Foxconn. Apple's decision to outsource its manufacturing has received significant criticism, due to allegations of poor working conditions, long work hours, and other labor rights violations. In response, Apple launched its Supplier Responsibility program, which aimed to improve Apple's oversight of supplier partners and enforce its ethics policies. It has also attempted to introduce greater diversification into its supply chain by sourcing products from other countries.

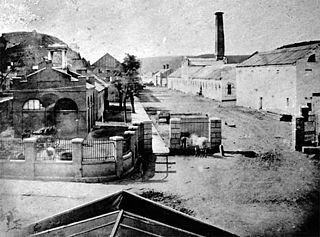

Coltsville Historic District is a National Historic Landmark District in Hartford, Connecticut. The district encompasses the factory, worker housing, and owner residences associated with Samuel Colt (1814-1862), one of the nation's early innovators in precision manufacturing and the production of firearms. It was the site of important contributions to manufacturing technology made by Colt and the industrial enterprise he created. Coltsville is a cohesive and readily identifiable 260-acre (110 ha) area, part of which was originally listed as the Colt Industrial District on the National Register of Historic Places in 1976. It was designated a National Historic Landmark in 2008.

Mesta Machinery was a leading industrial machinery manufacturer based in the Pittsburgh area town of West Homestead, Pennsylvania. It was founded in 1898 by George Mesta when he merged his machine shop with another. Mesta "machines" can be found in factories throughout the world and as of 1984 had equipment in 500 steel mills. Mesta was the 488th largest American company in 1958 and the 414th largest in 1959.

The 2021 Kellogg's strike was a labor strike started on October 5, 2021, and ended December 21, 2021, involving about 1,400 workers for food manufacturer Kellogg's, unionized as members of the Bakery, Confectionery, Tobacco Workers and Grain Millers' International Union (BCTGM). The strike was caused due to disagreements between the union and company concerning the terms of a new labor contract, with particular points of contention concerning the current two-tier wage system, health care, holidays, retirement benefits, cost-of-living adjustments, and vacation time. The strike affected all of Kellogg's cereal-producing plants in the United States, consisting of plants in Battle Creek, Michigan; Omaha, Nebraska; Lancaster, Pennsylvania; and Memphis, Tennessee. It is one of several strikes conducted by the BCTGM in 2021, including strike action against Frito-Lay and Nabisco.

References

- ↑ Hounshell, David A. (c. 1997). From the American system to mass production, 1800-1932 : the development of manufacturing technology in the United States . Hopkins Univ. Press. ISBN 0801829755. OCLC 254115836.

- ↑ Silver, Marc L. (2015). Under Construction : Work and Alienation in the Building Trades . State University of New York Press. ISBN 9781438420011. OCLC 1043360871.