The Jetex motor is a miniature solid-fuel rocket motor produced for use as a powerplant for flying model aircraft. Its production led to a number of imitators and, after its discontinuation, successors of similar type.

The Jetex motor is a miniature solid-fuel rocket motor produced for use as a powerplant for flying model aircraft. Its production led to a number of imitators and, after its discontinuation, successors of similar type.

Jetex was developed in 1947, by Wilmot, Mansour & Company Ltd of Southampton, which had started operations in a decommissioned hangar at RAF Beaulieu. [1] The first motor was demonstrated in early 1948 and was available to the public in June 1948, when Aeromodeller magazine featured Jetex power on its front cover. [2] The first motors were the Jetex 100 and 200, with the more powerful Jetex 350 following in November 1948. The most popular motor, the Jetex 50, was introduced in May 1949, along with kits for a model plane and model car using Jetex power. The subsequent popularity of Jetex led to the manufacture of numerous kits by third-party companies such as KeilKraft and Skyleada.

Jetex motors are powered by a solid pellet consisting mainly of guanidine nitrate, which burns to release an exhaust gas in large volume, leaving little solid residue. Thrust developed is modest and sustained, making it suitable for aerodynamically lifted flying models. The exhaust gas is not excessively hot, which confers a safety advantage.

Motors are loaded with one or more solid fuel pellets and a combustible 'wick' is led through the exhaust nozzle to ignite the fuel. Fuel and wick were manufactured by Imperial Chemical Industries (ICI). The engine casing of the early motors is made of an aluminium alloy. On introduction, fuel pellets and wick could be purchased separately, meaning that the system is reusable. [2]

Jetex power made a big impact in the late 1940s and early 1950s, allowing new sorts of models, scale and duration, to be designed. During the 1960s, Jetex propellant pellets found another use by AP Films/Century 21, in their 'Supermarionation' TV series, when they were fitted to the undersides of miniature ground vehicles to emit jets of gas resembling dust trails. [3]

Jetex went through a change of ownership in the mid 1950s. Gradually its popularity waned. Ron Baddorf speculated that the development of radio control and the increasing reliability and power of diesel motors caused a lack of interest in "the little Jetex". [4]

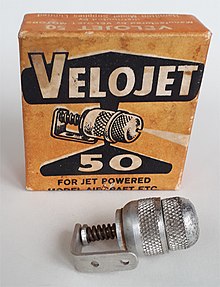

The Velojet 50 and its larger sibling, the Velojet 100, were New Zealand designed and manufactured. They used standard Jetex fuel and had a safety pressure release at the front in the form of a disc against a pre-tensioned coil spring. [5]

In 1986, Powermax in the UK launched a range of newly formulated size 50 fuel and wick under the Jet-X brand. [6] In the latter half of the 1990s, the company introduced their own 'Z' series motors, corresponding to the original Jetex 35, 50 and 100. From August 1995 Jet-X motors, fuel and fuse were commercially imported into the US. Flying Models told its readers that "safe and viable rocket power for model airplanes is back". [7]

Around the new millennium, a new non-reusable motor, called Rapier, was introduced. It has similar weight, thrust and duration to Jetex, allowing many old plans for Jetex powered models to be built and flown with the new motors. The Rapier is a single use motor with a cardboard case and a ceramic nozzle, visually closer to a model rocket motor than the original reloadable Jetex.

In early 2020, another range of non-reusable motors was introduced, called Tendera. These are similar to the Rapiers, being one-time use motors having cardboard cases and ceramic nozzles.

| Jetex Type | Thrust ounces | Tendera/Rapier equivalent | Thrust mN | |

|---|---|---|---|---|

| Jetex | 35 | 0.35 | L1 | 97 |

| Jetex | 50 | 0.50 | L2 | 139 |

| Jetex | 200 | 2.0 | L3 | 556 |

A jet engine is a type of reaction engine, discharging a fast-moving jet of heated gas that generates thrust by jet propulsion. While this broad definition may include rocket, water jet, and hybrid propulsion, the term jet engine typically refers to an internal combustion air-breathing jet engine such as a turbojet, turbofan, ramjet, pulse jet, or scramjet. In general, jet engines are internal combustion engines.

A rocket is a vehicle that uses jet propulsion to accelerate without using any surrounding air. A rocket engine produces thrust by reaction to exhaust expelled at high speed. Rocket engines work entirely from propellant carried within the vehicle; therefore a rocket can fly in the vacuum of space. Rockets work more efficiently in a vacuum and incur a loss of thrust due to the opposing pressure of the atmosphere.

A ramjet is a form of airbreathing jet engine that requires forward motion of the engine to provide air for combustion. Ramjets work most efficiently at supersonic speeds around Mach 3 and can operate up to Mach 6.

A solid-propellant rocket or solid rocket is a rocket with a rocket engine that uses solid propellants (fuel/oxidizer). The earliest rockets were solid-fuel rockets powered by gunpowder. The inception of gunpowder rockets in warfare can be credited to the ancient Chinese, and in the 13th century, the Mongols played a pivotal role in facilitating their westward adoption.

A turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft propulsion. The word "turbofan" is a combination of references to the preceding generation engine technology of the turbojet and the additional fan stage. It consists of a gas turbine engine which achieves mechanical energy from combustion, and a ducted fan that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet passes through the combustion chamber and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust.

A motorjet is a rudimentary type of jet engine which is sometimes referred to as thermojet, a term now commonly used to describe a particular and completely unrelated pulsejet design.

A rocket engine uses stored rocket propellants as the reaction mass for forming a high-speed propulsive jet of fluid, usually high-temperature gas. Rocket engines are reaction engines, producing thrust by ejecting mass rearward, in accordance with Newton's third law. Most rocket engines use the combustion of reactive chemicals to supply the necessary energy, but non-combusting forms such as cold gas thrusters and nuclear thermal rockets also exist. Vehicles propelled by rocket engines are commonly used by ballistic missiles and rockets. Rocket vehicles carry their own oxidiser, unlike most combustion engines, so rocket engines can be used in a vacuum to propel spacecraft and ballistic missiles.

A propellant is a mass that is expelled or expanded in such a way as to create a thrust or another motive force in accordance with Newton's third law of motion, and "propel" a vehicle, projectile, or fluid payload. In vehicles, the engine that expels the propellant is called a reaction engine. Although technically a propellant is the reaction mass used to create thrust, the term "propellant" is often used to describe a substance which contains both the reaction mass and the fuel that holds the energy used to accelerate the reaction mass. For example, the term "propellant" is often used in chemical rocket design to describe a combined fuel/propellant, although the propellants should not be confused with the fuel that is used by an engine to produce the energy that expels the propellant. Even though the byproducts of substances used as fuel are also often used as a reaction mass to create the thrust, such as with a chemical rocket engine, propellant and fuel are two distinct concepts.

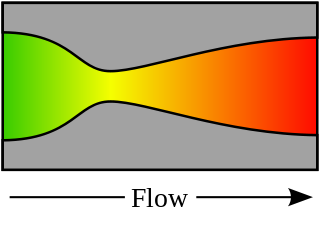

A nozzle is a device designed to control the direction or characteristics of a fluid flow as it exits an enclosed chamber or pipe.

The Delta rocket family was a versatile range of American rocket-powered expendable launch systems that provided space launch capability in the United States from 1960 to 2024. Japan also launched license-built derivatives from 1975 to 1992. More than 300 Delta rockets were launched with a 95% success rate. The series was phased out in favor of the Vulcan Centaur, with the Delta IV Heavy rocket's last launch occurring on April 9, 2024.

Thrust vectoring, also known as thrust vector control (TVC), is the ability of an aircraft, rocket or other vehicle to manipulate the direction of the thrust from its engine(s) or motor(s) to control the attitude or angular velocity of the vehicle.

A jet pack, rocket belt, rocket pack or flight pack is a device worn as a backpack which uses jets to propel the wearer through the air. The concept has been present in science fiction for almost a century and the first working experimental devices were demonstrated in the 1960s.

A propelling nozzle is a nozzle that converts the internal energy of a working gas into propulsive force; it is the nozzle, which forms a jet, that separates a gas turbine, or gas generator, from a jet engine.

Gimbaled thrust is the system of thrust vectoring used in most rockets, including the Space Shuttle, the Saturn V lunar rockets, and the Falcon 9.

A rocket engine nozzle is a propelling nozzle used in a rocket engine to expand and accelerate combustion products to high supersonic velocities.

Ammonium perchlorate composite propellant (APCP) is a solid rocket propellant. It differs from many traditional solid rocket propellants such as black powder or zinc-sulfur, not only in chemical composition and overall performance but also by being cast into shape, as opposed to powder pressing as with black powder. This provides manufacturing regularity and repeatability, which are necessary requirements for use in the aerospace industry.

The air turborocket is a form of combined-cycle jet engine. The basic layout includes a gas generator, which produces high pressure gas, that drives a turbine/compressor assembly which compresses atmospheric air into a combustion chamber. This mixture is then combusted before leaving the device through a nozzle and creating thrust.

This article briefly describes the components and systems found in jet engines.

Rocket propellant is used as reaction mass ejected from a rocket engine to produce thrust. The energy required can either come from the propellants themselves, as with a chemical rocket, or from an external source, as with ion engines.

The Bell Aerosystems Company XLR81 was an American liquid-propellant rocket engine, which was used on the Agena upper stage. It burned UDMH and RFNA fed by a turbopump in a fuel rich gas generator cycle. The turbopump had a single turbine with a gearbox to transmit power to the oxidizer and fuel pumps. The thrust chamber was all-aluminum, and regeneratively cooled by oxidizer flowing through gun-drilled passages in the combustion chamber and throat walls. The nozzle was a titanium radiatively cooled extension. The engine was mounted on a hydraulic actuated gimbal which enabled thrust vectoring to control pitch and yaw. Engine thrust and mixture ratio were controlled by cavitating flow venturis on the gas generator flow circuit. Engine start was achieved by solid propellant start cartridge.