Filtration is a physical separation process that separates solid matter and fluid from a mixture using a filter medium that has a complex structure through which only the fluid can pass. Solid particles that cannot pass through the filter medium are described as oversize and the fluid that passes through is called the filtrate. Oversize particles may form a filter cake on top of the filter and may also block the filter lattice, preventing the fluid phase from crossing the filter, known as blinding. The size of the largest particles that can successfully pass through a filter is called the effective pore size of that filter. The separation of solid and fluid is imperfect; solids will be contaminated with some fluid and filtrate will contain fine particles. Filtration occurs both in nature and in engineered systems; there are biological, geological, and industrial forms.

Water purification is the process of removing undesirable chemicals, biological contaminants, suspended solids, and gases from water. The goal is to produce water that is fit for specific purposes. Most water is purified and disinfected for human consumption, but water purification may also be carried out for a variety of other purposes, including medical, pharmacological, chemical, and industrial applications. The history of water purification includes a wide variety of methods. The methods used include physical processes such as filtration, sedimentation, and distillation; biological processes such as slow sand filters or biologically active carbon; chemical processes such as flocculation and chlorination; and the use of electromagnetic radiation such as ultraviolet light.

A media filter is a type of filter that uses a bed of sand, peat, shredded tires, foam, crushed glass, geo-textile fabric, anthracite, crushed granite or other material to filter water for drinking, swimming pools, aquaculture, irrigation, stormwater management, oil and gas operations, and other applications.

A water filter removes impurities by lowering contamination of water using a fine physical barrier, a chemical process, or a biological process. Filters cleanse water to different extents, for purposes such as: providing agricultural irrigation, accessible drinking water, public and private aquariums, and the safe use of ponds and swimming pools.

Slow sand filters are used in water purification for treating raw water to produce a potable product. They are typically 1–2 m (3.3–6.6 ft) deep, can be rectangular or cylindrical in cross section and are used primarily to treat surface water. The length and breadth of the tanks are determined by the flow rate desired for the filters, which typically have a loading rate of 200–400 litres (0.20–0.40 m3) per square metre per hour.

Sand filters are used as a step in the water treatment process of water purification.

In terms of water treatment, including water purification and sewage treatment, backwashing refers to pumping water backwards through the filters media, sometimes including intermittent use of compressed air during the process. Backwashing is a form of preventive maintenance so that the filter media can be reused. In water treatment plants, backwashing can be an automated process that is run by local programmable logic controllers (PLCs). The backwash cycle is triggered after a set time interval, when the filter effluent turbidity is greater than a treatment guideline or when the differential pressure across the filter exceeds a set value.

The McMillan Reservoir is a reservoir in Washington, D.C., that supplies the majority of the city's municipal water. It was originally called the Howard University Reservoir or the Washington City Reservoir, and was completed in 1902 by the U.S. Army Corps of Engineers.

The rapid sand filter or rapid gravity filter is a type of filter used in water purification and is commonly used in municipal drinking water facilities as part of a multiple-stage treatment system. These systems are complex and expensive to operate and maintain, and therefore less suitable for small communities and developing nations.

Aquarium filters are critical components of both freshwater and marine aquaria. Aquarium filters remove physical and soluble chemical waste products from aquaria, simplifying maintenance. Furthermore, aquarium filters are necessary to support life as aquaria are relatively small, closed volumes of water compared to the natural environment of most fish.

Depth filters are filters that use a porous filtration medium to retain particles throughout the medium, rather than just on the surface of the medium. Depth filtration, typified by multiple porous layers with depth, is used to capture the solid contaminants from the liquid phase. These filters are commonly used when the fluid to be filtered contains a high load of particles because, relative to other types of filters, they can retain a large mass of particles before becoming clogged. With ongoing advances in process technologies depth filter designs are continuously adapting and improving to meet the needs of industry.

The history of water filters can be traced to the earliest civilisations with written records. Water filters have been used throughout history to improve the safety and aesthetics of water intended to be used for drinking or bathing. In modern times, they are also widely used in industry and commerce. The history of water filtration is closely linked with the broader history of improvements in public health.

The history of water supply and sanitation is one of a logistical challenge to provide clean water and sanitation systems since the dawn of civilization. Where water resources, infrastructure or sanitation systems were insufficient, diseases spread and people fell sick or died prematurely.

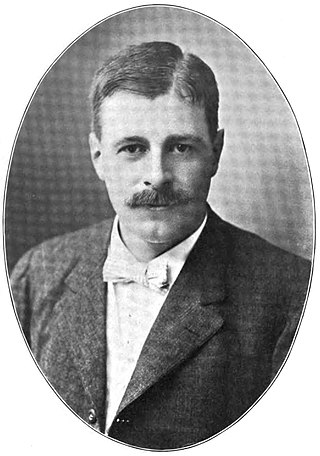

George Warren Fuller was an American sanitary engineer who was also trained in bacteriology and chemistry. His career extended from 1890 to 1934 and he was responsible for important innovations in water and wastewater treatment. He designed and built the first modern water filtration plant, and he designed and built the first chlorination system that disinfected a U.S. drinking water supply. In addition, he performed groundbreaking engineering work on sewage treatment facilities in the U.S. He was President of both the American Water Works Association and the American Public Health Association, and he was recognized internationally as an expert civil and sanitary engineer.

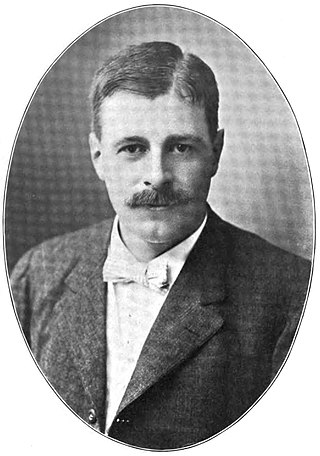

Allen Hazen was an American civil engineer and an expert in hydraulics, flood control, water purification and sewage treatment. His career extended from 1888 to 1930, and he is, perhaps, best known for his contributions to hydraulics with the Hazen-Williams equation. Hazen published some of the seminal works on sedimentation and filtration. He was President of the New England Water Works Association and Vice President of the American Society of Civil Engineers.

John Robert Baylis was an American chemist and sanitary engineer. His career extended from about 1905 to 1963 and he is best known for his work in applied research to improve drinking water purification.

Water chlorination is the process of adding chlorine or chlorine compounds such as sodium hypochlorite to water. This method is used to kill bacteria, viruses and other microbes in water. In particular, chlorination is used to prevent the spread of waterborne diseases such as cholera, dysentery, and typhoid.

The development of water treatment and filtration technologies went through many stages. The greatest level of change came in the 19th century as the growth of cities forced the development of new methods for distributing and treating water and the problems of water contamination became more pronounced.

The Walton water treatment works are an advanced purification works supplied with raw water and producing and delivering potable water to the locality and into the Thames Water ring main. The Walton water treatment works were initially built in 1907 north of the Bessborough and Knight reservoirs which supply the water works.