A land mine is an explosive device concealed under or on the ground and designed to destroy or disable enemy targets, ranging from combatants to vehicles and tanks, as they pass over or near it. Such a device is typically detonated automatically by way of pressure when a target steps on it or drives over it, although other detonation mechanisms are also sometimes used. A land mine may cause damage by direct blast effect, by fragments that are thrown by the blast, or by both.

The GATOR mine system is a United States military system of air-dropped anti-tank and anti-personnel mines developed in the 1980s to be compatible with existing cluster dispensers. It is used with two dispenser systems—the Navy 230 kg (500 lb) CBU-78/B and the Air Force 450 kg (1,000 lb) CBU-89/B. Additionally the mines are used with the land- and helicopter-based Volcano mine system.

An anti-tank mine is a type of land mine designed to damage or destroy vehicles including tanks and armored fighting vehicles.

FV103 Spartan is a tracked armoured personnel carrier of the British Army. It was developed as the APC variant of the Combat Vehicle Reconnaissance (Tracked) family. The vehicle can carry up to seven personnel, including three crew members. Armed with a single machine gun, it is almost indistinguishable from the FV102 Striker in external appearance. Rather than a general personnel carrier for infantry, the Spartan has been used for moving specialist teams, such as anti-aircraft missile teams. An anti-tank variant of the Spartan has been produced, named FV120 Spartan MCT; this is armed with MILAN anti-tank missiles. Nearly 500 Spartans have served with the British armed forces since entering service in 1978; they are now being replaced by newer vehicles.

The FV432 is the armoured personnel carrier variant of the British Army's FV430 series of armoured fighting vehicles. Since its introduction in the 1960s, it has been the most common variant, being used for transporting infantry on the battlefield. In the 1980s, almost 2,500 vehicles were in use, with around 500 now remaining in operation - mostly in supporting arms rather than front-line infantry service.

The Grenade, Hand, Anti-Tank, No. 75, also known as the "Hawkins grenade" was a British anti-tank hand grenade used during World War II. It was one of a number of grenades developed for use by the British Army and Home Guard in the aftermath of the Dunkirk evacuation. The grenade first appeared in 1942, and was designed to be more versatile than previous grenades, such as the No. 73 grenade and the sticky bomb.

A mine flail is a vehicle-mounted device that makes a safe path through a minefield by deliberately detonating land mines in front of the vehicle that carries it. They were first used by the British during World War II.

The Giant Viper is a trailer-mounted, vehicle-pulled, mine clearance system, designed to be deployed in areas containing land mines. It was developed for the British Army in the 1950s. It was designed to be towed behind a Centurion gun tank, FV4003, AVRE ; and also the FV432 Armoured personnel carrier.

Anti-personnel mines are a form of mine designed for use against humans, as opposed to anti-tank mines, which are designed for use against vehicles. Anti-personnel mines may be classified into blast mines or fragmentation mines, the latter may or may not be a bounding mine.

The VS-50 is a circular plastic cased anti-personnel blast mine, formerly manufactured by the now-defunct Valsella Meccanotecnica SpA, an Italian high-tech defence industry specialized in area denial systems which was also the manufacturer of the Valmara 69 and one of the first industries in the world to implement plastic construction for landmines. The design is similar to the TS-50 and VS-MK2 mine. It is blast resistant and can be used in a minimum metal configuration. Though unlikely to kill, the explosive charge contained within a VS-50 is quite sufficient to destroy the victim's foot: the blast is capable of penetrating 5 mm of mild steel leaving an 80 mm-diameter hole.

TM-62 is the designation for a series of Soviet anti-tank blast mines. The mines have a central fuze and typically have a 7.5 kg explosive charge, however they vary greatly in detail. The mines can be laid manually or automatically from a mine laying machine including the PMR-1, PMR-2 wheeled towed mine layers, the GMZ tracked mine laying vehicle and the VMR-2 helicopter mine laying system.

The PRB M3 and PRB M3A1 are plastic cased minimum metal anti-tank blast mine produced by the Belgian company Poudreries Réunies de Belgique in the 1970s and 1980s. The mine is square with an olive drab body constructed from polythene with a webbing carrying handle on the side and an ammonia-free bakelite seating for the pressure plate to be screwed into. The fuze well is in the centre of the seating, with the pressure plate screwed into it after the fuze has been inserted. The cylindrical pressure plate consists of two plastic plates, one of which moves under the weight of a vehicle driving over the mine to transmit the force to the fuze, shearing pins which hold it in place.

The Mk 7 mine was a circular British anti-tank blast mine. It replaced the World War 2-era Mk 5 mine, and has in turn been replaced by the L9 Bar Mine.

A Blast resistant mine is a landmine with a fuze which is designed to be insensitive to the shock wave from a nearby explosion. This feature makes it difficult or impossible to clear such mines using explosive minefield breaching techniques. As a result, the process of clearing minefields is slower and more complex. Blast resistance can be achieved in a number of ways.

An anti-handling device is an attachment to or an integral part of a landmine or other munition such as some fuze types found in general-purpose air-dropped bombs, cluster bombs and sea mines. It is designed to prevent tampering or disabling, or to target bomb disposal personnel. When the protected device is disturbed, it detonates, killing or injuring anyone within the blast area. There is a strong functional overlap of booby traps and anti-handling devices.

The VAR/40, VAR/100 and VAR/100/SP are Italian anti-personnel blast landmines produced by the Tecnovar italiana S.p.A. company.

The M1936 (Mle1936) is a French light anti-tank mine used during the Second World War. The mine was captured in large numbers by the German army after the Fall of France, and was later used in the Atlantikwall, North Africa and Italy. The mine consists of a base plate on top of which is a rectangular steel box containing an explosive charge. On top of the container are two M1935 or M1936 pressure fuzes. A pressure cover is fixed on top of the container by wires attached at either end of the container. Two pressure bars are welded to the inside of the pressure cover, each one is directly over a fuze—however, each bar has a recess preventing it from pressing on the pressure fuze, until a safety bar is inserted. The safety bar covers the recesses allowing the pressure cover to bear down directly on the pressure fuzes.

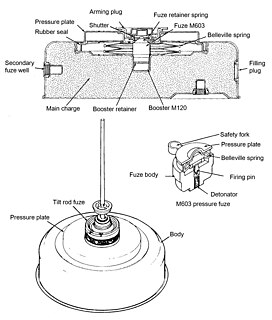

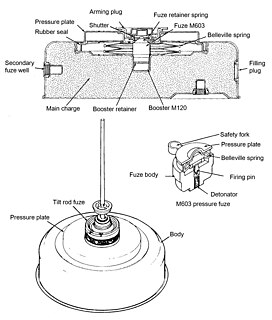

A tilt-rod fuze is a device used to trigger anti-vehicle landmines. Typically it consists of a vertical pole, normally around a meter high, which is connected to the top of a landmine. When the track or main body of a vehicle passes over the mine, the rod is tilted, releasing a spring-loaded striker which triggers a pyrotechnic delay of approximately half a second, followed by detonation of the main explosive charge. The small time delay allows the vehicle to continue over the mine before detonating, exposing more of it to the blast. A tilt-rod fuze has a number of advantages over pressure fuzes - it acts across the entire width of a vehicle, rather than just its tracks or tires. This allows it to attack the vehicle's belly and potentially cause a catastrophic kill. Additionally, tilt rod fuzes tend to be resistant to blast overpressure clearing methods, which can trigger most pressure fuzes.

Armoured Vehicle Royal Engineers (AVRE), also known as Assault Vehicle Royal Engineers is the title given to a series of armoured military engineering vehicles operated by the Royal Engineers (RE) for the purpose of protecting engineers during frontline battlefield operations.

The L10 Ranger Anti-Personnel Mine was a United Kingdom anti-personnel blast mine. It was used from the 1970s until recently.