A nuclear reactor is a device used to initiate and control a fission nuclear chain reaction or nuclear fusion reactions. Nuclear reactors are used at nuclear power plants for electricity generation and in nuclear marine propulsion. Heat from nuclear fission is passed to a working fluid, which in turn runs through steam turbines. These either drive a ship's propellers or turn electrical generators' shafts. Nuclear generated steam in principle can be used for industrial process heat or for district heating. Some reactors are used to produce isotopes for medical and industrial use, or for production of weapons-grade plutonium. As of 2022, the International Atomic Energy Agency reports there are 422 nuclear power reactors and 223 nuclear research reactors in operation around the world.

A boiling water reactor (BWR) is a type of light water nuclear reactor used for the generation of electrical power. It is the second most common type of electricity-generating nuclear reactor after the pressurized water reactor (PWR), which is also a type of light water nuclear reactor.

A nuclear meltdown is a severe nuclear reactor accident that results in core damage from overheating. The term nuclear meltdown is not officially defined by the International Atomic Energy Agency or by the United States Nuclear Regulatory Commission. It has been defined to mean the accidental melting of the core of a nuclear reactor, however, and is in common usage a reference to the core's either complete or partial collapse.

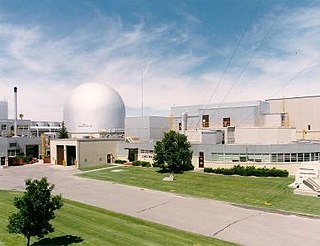

Idaho National Laboratory (INL) is one of the national laboratories of the United States Department of Energy and is managed by the Battelle Energy Alliance. Historically, the lab has been involved with nuclear research, although the laboratory does other research as well. Much of current knowledge about how nuclear reactors behave and misbehave was discovered at what is now Idaho National Laboratory. John Grossenbacher, former INL director, said, "The history of nuclear energy for peaceful application has principally been written in Idaho".

The light-water reactor (LWR) is a type of thermal-neutron reactor that uses normal water, as opposed to heavy water, as both its coolant and neutron moderator; furthermore a solid form of fissile elements is used as fuel. Thermal-neutron reactors are the most common type of nuclear reactor, and light-water reactors are the most common type of thermal-neutron reactor.

Passive nuclear safety is a design approach for safety features, implemented in a nuclear reactor, that does not require any active intervention on the part of the operator or electrical/electronic feedback in order to bring the reactor to a safe shutdown state, in the event of a particular type of emergency. Such design features tend to rely on the engineering of components such that their predicted behaviour would slow down, rather than accelerate the deterioration of the reactor state; they typically take advantage of natural forces or phenomena such as gravity, buoyancy, pressure differences, conduction or natural heat convection to accomplish safety functions without requiring an active power source. Many older common reactor designs use passive safety systems to a limited extent, rather, relying on active safety systems such as diesel powered motors. Some newer reactor designs feature more passive systems; the motivation being that they are highly reliable and reduce the cost associated with the installation and maintenance of systems that would otherwise require multiple trains of equipment and redundant safety class power supplies in order to achieve the same level of reliability. However, weak driving forces that power many passive safety features can pose significant challenges to effectiveness of a passive system, particularly in the short term following an accident.

The integral fast reactor is a design for a nuclear reactor using fast neutrons and no neutron moderator. IFR would breed more fuel and is distinguished by a nuclear fuel cycle that uses reprocessing via electrorefining at the reactor site.

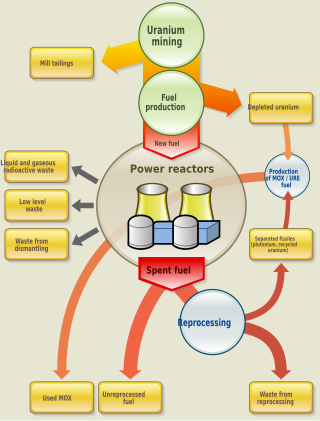

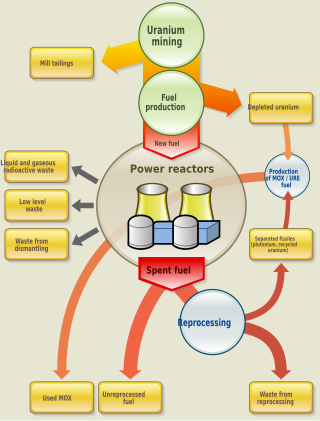

Nuclear fuel is material used in nuclear power stations to produce heat to power turbines. Heat is created when nuclear fuel undergoes nuclear fission.

The Bhabha Atomic Research Centre (BARC) is India's premier nuclear research facility, headquartered in Trombay, Mumbai, Maharashtra, India. It was founded by Homi Jehangir Bhabha as the Atomic Energy Establishment, Trombay (AEET) in January 1954 as a multidisciplinary research program essential for India's nuclear program. It operates under the Department of Atomic Energy (DAE), which is directly overseen by the Prime Minister of India.

Indira Gandhi Centre for Atomic Research(IGCAR) is one of India's premier nuclear research centres. It is the second largest establishment of the Department of Atomic Energy (DAE), next to Bhabha Atomic Research Centre (BARC), located at Kalpakkam, 80 km south of Chennai, India. It was established in 1971 as an exclusive centre dedicated to the pursuit of fast reactor science and technology, due to the vision of Dr. Vikram Sarabhai. Originally, it was called as Reactor Research Centre (RRC). It was renamed as Indira Gandhi Centre for Atomic Research(IGCAR) by the then Prime Minister of India, Rajiv Gandhi in December 1985. The centre is engaged in broad-based multidisciplinary programme of scientific research and advanced engineering directed towards the development of Fast Breeder Reactor technology, in India.

Spent fuel pools (SFP) are storage pools for spent fuel from nuclear reactors. They are typically 40 or more feet (12 m) deep, with the bottom 14 feet equipped with storage racks designed to hold fuel assemblies removed from reactors. A reactor's local pool is specially designed for the reactor in which the fuel was used and is situated at the reactor site. Such pools are used for short-term cooling of the fuel rods. This allows short-lived isotopes to decay and thus reduces the ionizing radiation and decay heat emanating from the rods. The water cools the fuel and provides radiological protection from its radiation.

The supercritical water reactor (SCWR) is a concept Generation IV reactor, designed as a light water reactor (LWR) that operates at supercritical pressure. The term critical in this context refers to the critical point of water, and must not be confused with the concept of criticality of the nuclear reactor.

Generation IV reactors are nuclear reactor design technologies that are envisioned as successors of generation III reactors. The Generation IV International Forum (GIF) - an international organization that coordinates the development of generation IV reactors - specifically selected six reactor technologies as candidates for generation IV reactors. The designs target improved safety, sustainability, efficiency, and cost. The first commercial Gen IV plants are not expected before 2040–2050, although the World Nuclear Association in 2015 suggested that some might enter commercial operation before 2030.

Generation III reactors, or Gen III reactors, are a class of nuclear reactors designed to succeed Generation II reactors, incorporating evolutionary improvements in design. These include improved fuel technology, higher thermal efficiency, significantly enhanced safety systems, and standardized designs intended to reduce maintenance and capital costs. They are promoted by the Generation IV International Forum (GIF).

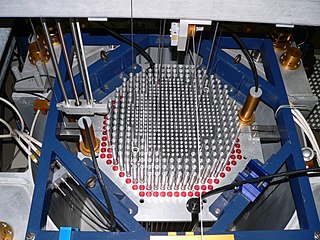

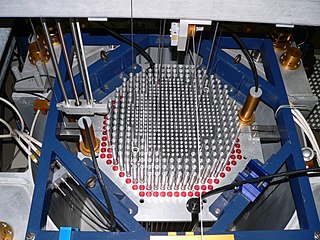

The Advanced Test Reactor (ATR) is a research reactor at the Idaho National Laboratory, located east of Arco, Idaho. This reactor was designed and is used to test nuclear fuels and materials to be used in power plants, naval propulsion, research and advanced reactors. It can operate at a maximum thermal power of 250 MW and has a "Four Leaf Clover" core design that allows for a variety of testing locations. The unique design allows for different neutron flux conditions in various locations. Six of the test locations allow an experiment to be isolated from the primary cooling system, providing its own environment for temperature, pressure, flow and chemistry, replicating the physical environment while accelerating the nuclear conditions.

In nuclear power technology, burnup is a measure of how much energy is extracted from a primary nuclear fuel source. It is measured as the fraction of fuel atoms that underwent fission in %FIMA or %FIFA as well as, preferably, the actual energy released per mass of initial fuel in gigawatt-days/metric ton of heavy metal (GWd/tHM), or similar units.

The Energy Multiplier Module is a nuclear fission power reactor under development by General Atomics. It is a fast-neutron version of the Gas Turbine Modular Helium Reactor (GT-MHR) and is capable of converting spent nuclear fuel into electricity and industrial process heat.

Consortium for the Advanced Simulation of Light Water Reactors (CASL) is an Energy Innovation Hub sponsored by United States Department of Energy (DOE) and based at Oak Ridge National Laboratory (ORNL). CASL combines fundamental research and technology development through an integrated partnership of government, academia, and industry that extends across the nuclear energy enterprise. The goal of CASL is to develop advanced computational models of light water reactors (LWRs) that can be used by utilities, fuel vendors, universities, and national laboratories to help improve the performance of existing and future nuclear reactors. CASL was created in May 2010, and was the first energy innovation hub to be awarded.

The APR-1400 is an advanced pressurized water nuclear reactor designed by the Korea Electric Power Corporation (KEPCO). Originally known as the Korean Next Generation Reactor (KNGR), this Generation III reactor was developed from the earlier OPR-1000 design and also incorporates features from the US Combustion Engineering (C-E) System 80+ design. Currently in South Korea there are 3 units in operation, and 3 units in construction. Three units are completed and in commercial operation in the United Arab Emirates at Barakah, with one more under construction at the same plant.

Nuclear Safety, Research, Demonstration, and Development Act of 1980, 42 U.S.C. § 9701, established nuclear safety policy for nuclear power plants supplying electric energy and electricity generation within the United States. The Act authorized a five-year demonstration program simulating conditions with light water nuclear reactors for the observation of control monitoring and phases of operation for nuclear reactor cores. The U.S. Department of Energy was authorized by the Act of Congress to conduct the nuclear reactor demonstration study while establishing a reactor engineering simulator facility at a United States national laboratory. The nuclear safety demonstration program was to provide research data regarding reactor design and simplification improvements given thermal power station simulations subjecting nuclear reactors to hypothesized calamity and customary operating conditions.