In physics, a fluid is a liquid, gas, or other material that may continuously move and deform (flow) under an applied shear stress, or external force. They have zero shear modulus, or, in simpler terms, are substances which cannot resist any shear force applied to them.

Rheology is the study of the flow of matter, primarily in a fluid state but also as "soft solids" or solids under conditions in which they respond with plastic flow rather than deforming elastically in response to an applied force. Rheology is the branch of physics that deals with the deformation and flow of materials, both solids and liquids.

A viscometer is an instrument used to measure the viscosity of a fluid. For liquids with viscosities which vary with flow conditions, an instrument called a rheometer is used. Thus, a rheometer can be considered as a special type of viscometer. Viscometers can measure only constant viscosity, that is, viscosity that does not change with flow conditions.

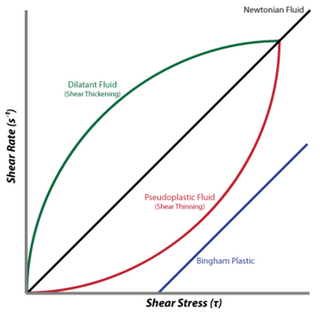

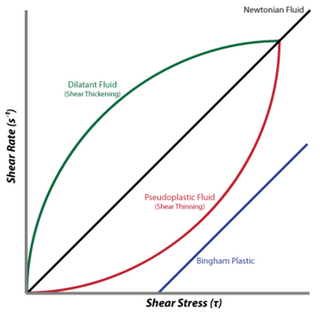

In physics and chemistry, a non-Newtonian fluid is a fluid that does not follow Newton's law of viscosity, that is, it has variable viscosity dependent on stress. In particular, the viscosity of non-Newtonian fluids can change when subjected to force. Ketchup, for example, becomes runnier when shaken and is thus a non-Newtonian fluid. Many salt solutions and molten polymers are non-Newtonian fluids, as are many commonly found substances such as custard, toothpaste, starch suspensions, corn starch, paint, blood, melted butter and shampoo.

A bulletproof vest, also known as a ballistic vest or bullet-resistant vest, is a type of body armour designed to absorb impact and prevent the penetration of firearm projectiles and explosion fragments to the torso. The vest can be either soft—as worn by police officers, security personnel, prison guards, and occasionally private citizens to protect against stabbing attacks or light projectiles—or hard, incorporating metallic or para-aramid components. Soldiers and police tactical units typically wear hard armour, either alone or combined with soft armour, to protect against rifle ammunition or fragmentation. Additional protection includes trauma plates for blunt force and ceramic inserts for high-caliber rounds. Bulletproof vests have evolved over centuries, from early designs like those made for knights and military leaders to modern-day versions. Early ballistic protection used materials like cotton and silk, while contemporary vests employ advanced fibers and ceramic plates. Ongoing research focuses on improving materials and effectiveness against emerging threats.

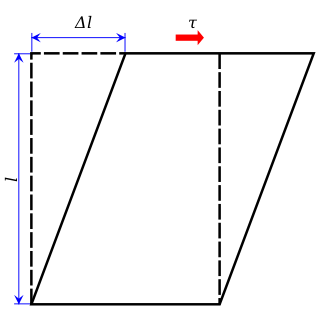

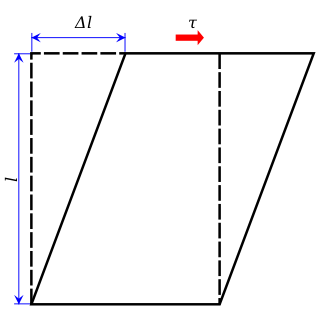

Shear stress is the component of stress coplanar with a material cross section. It arises from the shear force, the component of force vector parallel to the material cross section. Normal stress, on the other hand, arises from the force vector component perpendicular to the material cross section on which it acts.

A magnetorheological fluid is a type of smart fluid in a carrier fluid, usually a type of oil. When subjected to a magnetic field, the fluid greatly increases its apparent viscosity, to the point of becoming a viscoelastic solid. Importantly, the yield stress of the fluid when in its active ("on") state can be controlled very accurately by varying the magnetic field intensity. The upshot is that the fluid's ability to transmit force can be controlled with an electromagnet, which gives rise to its many possible control-based applications.

A dilatant material is one in which viscosity increases with the rate of shear strain. Such a shear thickening fluid, also known by the initialism STF, is an example of a non-Newtonian fluid. This behaviour is usually not observed in pure materials, but can occur in suspensions.

Soil mechanics is a branch of soil physics and applied mechanics that describes the behavior of soils. It differs from fluid mechanics and solid mechanics in the sense that soils consist of a heterogeneous mixture of fluids and particles but soil may also contain organic solids and other matter. Along with rock mechanics, soil mechanics provides the theoretical basis for analysis in geotechnical engineering, a subdiscipline of civil engineering, and engineering geology, a subdiscipline of geology. Soil mechanics is used to analyze the deformations of and flow of fluids within natural and man-made structures that are supported on or made of soil, or structures that are buried in soils. Example applications are building and bridge foundations, retaining walls, dams, and buried pipeline systems. Principles of soil mechanics are also used in related disciplines such as geophysical engineering, coastal engineering, agricultural engineering, and hydrology.

Body armor, personal armor, armored suit (armoured) or coat of armor, among others, is armor for a person's body: protective clothing or close-fitting hands-free shields designed to absorb or deflect physical attacks. Historically used to protect military personnel, today it is also used by various types of police, private security guards, or bodyguards, and occasionally ordinary citizens. Today there are two main types: regular non-plated body armor for moderate to substantial protection, and hard-plate reinforced body armor for maximum protection, such as used by combatants.

Electrorheological (ER) fluids are suspensions of extremely fine non-conducting but electrically active particles in an electrically insulating fluid. The apparent viscosity of these fluids changes reversibly by an order of up to 100,000 in response to an electric field. For example, a typical ER fluid can go from the consistency of a liquid to that of a gel, and back, with response times on the order of milliseconds. The effect is sometimes called the Winslow effect after its discoverer, the American inventor Willis Winslow, who obtained a US patent on the effect in 1947 and wrote an article published in 1949.

In continuum mechanics, rheopecty or rheopexy is the rare property of some non-Newtonian fluids to show a time-dependent increase in viscosity ; the longer the fluid undergoes shearing force, the higher its viscosity. Rheopectic fluids, such as some lubricants, thicken or solidify when shaken. The opposite and much more common type of behaviour, in which fluids become less viscous the longer they undergo shear, is called thixotropy.

Gold Flex is a non-woven fabric manufactured by Honeywell from Kevlar, and is often used in ballistic vests and body armor. Gold Flex is lighter than woven Kevlar, Twaron and other Ballistic material. Gold Flex is a laminated material consisting of cross-laid, non-woven fibers in a resin matrix. The fibers are laid straight and not in a woven fabric configuration. When an object strikes this material, a "web" of its clusters absorb the impact and minimizes penetration.

Rheometry generically refers to the experimental techniques used to determine the rheological properties of materials, that is the qualitative and quantitative relationships between stresses and strains and their derivatives. The techniques used are experimental. Rheometry investigates materials in relatively simple flows like steady shear flow, small amplitude oscillatory shear, and extensional flow.

In rheology, shear thinning is the non-Newtonian behavior of fluids whose viscosity decreases under shear strain. It is sometimes considered synonymous for pseudo-plastic behaviour, and is usually defined as excluding time-dependent effects, such as thixotropy.

In fluid dynamics, the no-slip condition is a boundary condition which enforces that at a solid boundary, a viscous fluid attains zero bulk velocity. This boundary condition was first proposed by Osborne Reynolds, who observed this behaviour while performing his influential pipe flow experiments. The form of this boundary condition is an example of a Dirichlet boundary condition.

Soldier 2025 is a United States Army research and development project to create an advanced, high-tech combat uniform for U.S. infantry soldiers. The features of this outfit include nanotechnology, built-in sensors, and physical augmentations.

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water. Viscosity is defined scientifically as a force multiplied by a time divided by an area. Thus its SI units are newton-seconds per square meter, or pascal-seconds.

In continuum mechanics, time-dependent viscosity is a property of fluids whose viscosity changes as a function of time. The most common type of this is thixotropy, in which the viscosity of fluids under continuous shear decreases with time; the opposite is rheopecty, in which viscosity increases with time.