Related Research Articles

The Space Shuttle is a retired, partially reusable low Earth orbital spacecraft system operated from 1981 to 2011 by the U.S. National Aeronautics and Space Administration (NASA) as part of the Space Shuttle program. Its official program name was Space Transportation System (STS), taken from a 1969 plan for a system of reusable spacecraft where it was the only item funded for development. The first (STS-1) of four orbital test flights occurred in 1981, leading to operational flights (STS-5) beginning in 1982. Five complete Space Shuttle orbiter vehicles were built and flown on a total of 135 missions from 1981 to 2011, launched from the Kennedy Space Center (KSC) in Florida. Operational missions launched numerous satellites, interplanetary probes, and the Hubble Space Telescope (HST), conducted science experiments in orbit, participated in the Shuttle-Mir program with Russia, and participated in construction and servicing of the International Space Station (ISS). The Space Shuttle fleet's total mission time was 1,323 days.

A single-stage-to-orbit vehicle reaches orbit from the surface of a body using only propellants and fluids and without expending tanks, engines, or other major hardware. The term usually, but not exclusively, refers to reusable vehicles. To date, no Earth-launched SSTO launch vehicles have ever been flown; orbital launches from Earth have been performed by either fully or partially expendable multi-stage rockets.

The Buran program, also known as the "VKK Space Orbiter programme", was a Soviet and later Russian reusable spacecraft project that began in 1974 at the Central Aerohydrodynamic Institute in Moscow and was formally suspended in 1993. In addition to being the designation for the whole Soviet/Russian reusable spacecraft project, Buran was also the name given to Orbiter K1, which completed one uncrewed spaceflight in 1988 and was the only Soviet reusable spacecraft to be launched into space. The Buran-class orbiters used the expendable Energia rocket as a launch vehicle. Unlike the Space Shuttle, Buran had a capability of flying uncrewed missions, as well as performing fully automated landings.

A lifting body is a fixed-wing aircraft or spacecraft configuration in which the body itself produces lift. In contrast to a flying wing, which is a wing with minimal or no conventional fuselage, a lifting body can be thought of as a fuselage with little or no conventional wing. Whereas a flying wing seeks to maximize cruise efficiency at subsonic speeds by eliminating non-lifting surfaces, lifting bodies generally minimize the drag and structure of a wing for subsonic, supersonic and hypersonic flight, or spacecraft re-entry. All of these flight regimes pose challenges for proper flight safety.

A reusable launch vehicle have parts that can be recovered and reflown, while carrying payloads from the surface to outer space. Rocket stages are the most common launch vehicle parts aimed for reuse. Smaller parts such as rocket engines and boosters can also be reused, though reusable spacecraft may be launched on top of an expendable launch vehicle. Reusable launch vehicles do not need to make these parts for each launch, therefore reducing its launch cost significantly. However, these benefits are diminished by the cost of recovery and refurbishment.

A spaceplane is a vehicle that can fly and glide like an aircraft in Earth's atmosphere and maneuver like a spacecraft in outer space. To do so, spaceplanes must incorporate features of both aircraft and spacecraft. Orbital spaceplanes tend to be more similar to conventional spacecraft, while sub-orbital spaceplanes tend to be more similar to fixed-wing aircraft. All spaceplanes to date have been rocket-powered but then landed as unpowered gliders.

VentureStar was a single-stage-to-orbit reusable launch system proposed by Lockheed Martin and funded by the U.S. government. The goal was to replace the Space Shuttle by developing a re-usable spaceplane that could launch satellites into orbit at a fraction of the cost. While the requirement was for an uncrewed launcher, it was expected to carry passengers as cargo. The VentureStar would have had a wingspan of 68 feet (20.7 m), a length of 127 feet (38.7 m), and would have weighed roughly 1000 t.

The Lockheed Martin X-33 was a proposed uncrewed, sub-scale technology demonstrator suborbital spaceplane that was developed for a period in the 1990s. The X-33 was a technology demonstrator for the VentureStar orbital spaceplane, which was planned to be a next-generation, commercially operated reusable launch vehicle. The X-33 would flight-test a range of technologies that NASA believed it needed for single-stage-to-orbit reusable launch vehicles, such as metallic thermal protection systems, composite cryogenic fuel tanks for liquid hydrogen, the aerospike engine, autonomous (uncrewed) flight control, rapid flight turn-around times through streamlined operations, and its lifting body aerodynamics.

The DC-X, short for Delta Clipper or Delta Clipper Experimental, was an uncrewed prototype of a reusable single-stage-to-orbit launch vehicle built by McDonnell Douglas in conjunction with the United States Department of Defense's Strategic Defense Initiative Organization (SDIO) from 1991 to 1993. Starting 1994 until 1995, testing continued through funding of the US civil space agency NASA. In 1996, the DC-X technology was completely transferred to NASA, which upgraded the design for improved performance to create the DC-XA.

A launch vehicle or carrier rocket can carry a payload from the surface to outer space, such as spacecraft and satellites. They are often operated with extensive infrastructure such as launch pads, vehicle assembly, fueling systems, range safety, etc. The difficulties of spaceflight demand launch vehicles to be engineered with very advanced aerodynamics and technologies – a big contributor to the vehicle's expensive operating cost.

Shuttle-derived vehicle (SDV) is a term describing one of an array of concepts that have been developed for building space launch vehicles and spacecraft using the already developed components, technology, and infrastructure of the Space Shuttle program.

The Space Transportation System (STS), also known internally to NASA as the Integrated Program Plan (IPP), was a proposed system of reusable crewed space vehicles envisioned in 1969 to support extended operations beyond the Apollo program.. The purpose of the system was two-fold: to reduce the cost of spaceflight by replacing the current method of launching capsules on expendable rockets with reusable spacecraft; and to support ambitious follow-on programs including permanent orbiting space stations around Earth and the Moon, and a human landing mission to Mars.

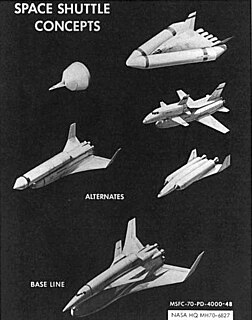

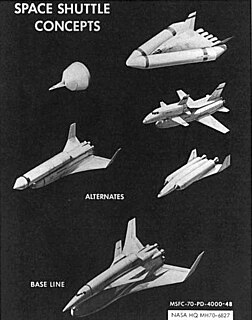

Before the Apollo 11 Moon landing in 1969, NASA began studies of Space Shuttle designs as early as October 1968. The early studies were denoted "Phase A", and in June 1970, "Phase B", which were more detailed and specific. The primary intended use of the Space Shuttle was supporting the future space station, ferrying a minimum crew of four and about 20,000 pounds (9,100 kg) of cargo, and able to be rapidly turned around for future flights.

The DC-3 was one of several early design proposals for the NASA Space Shuttle designed by Maxime Faget at the Manned Spacecraft Center (MSC) in Houston. It was nominally developed by North American Aviation (NAA), although it was a purely NASA-internal design. Unlike the design that eventually emerged, the DC-3 was a fully reusable launch vehicle two-stage-to-orbit spaceplane design with a small payload capacity of about 12,000 lb (5,400 kg) and limited maneuverability. Its inherent strengths were good low-speed handling during landing, and a low-risk development that was relatively immune to changes in weight and balance.

SERV, short for Single-stage Earth-orbital Reusable Vehicle, was a proposed space launch system designed by Chrysler's Space Division for the Space Shuttle project. SERV was so radically different from the two-stage spaceplanes that almost every other competitor entered into the Shuttle development process that it was never seriously considered for the shuttle program.

A rocket sled launch, also known as ground-based launch assist, catapult launch assist, and sky-ramp launch, is a proposed method for launching space vehicles. With this concept the launch vehicle is supported by an eastward pointing rail or maglev track that goes up the side of a mountain while an externally applied force is used to accelerate the launch vehicle to a given velocity. Using an externally applied force for the initial acceleration reduces the propellant the launch vehicle needs to carry to reach orbit. This allows the launch vehicle to carry a larger payload and reduces the cost of getting to orbit. When the amount of velocity added to the launch vehicle by the ground accelerator becomes great enough, single-stage-to-orbit flight with a reusable launch vehicle becomes possible.

Aircraft can have different ways to take off and land. Conventional airplanes accelerate along the ground until sufficient lift is generated for takeoff, and reverse the process to land. Some airplanes can take off at low speed, this being a short takeoff. Some aircraft such as helicopters and Harrier Jump Jets can take off and land vertically. Rockets also usually take off vertically, but some designs can land horizontally.

During the lifetime of Space Shuttle, Rockwell International and many other organizations studied various Space Shuttle designs. These studies included different ways to increase shuttle payload capability, crew capacity, and developing standalone reusable launch vehicles. A large focus of the program was towards new shuttle boosters and an upgrades to the external tank but also looked to expand NASA's ability to launch deep space missions and build large modular space stations. Many of these concepts and studies would shape the concepts and programs of the 2000s such as Constellation, Orbital Space Plane Program, and Artemis program.

SNC Demo-1, also known as Dream Chaser Demo-1, is the planned first flight of the Sierra Nevada robotic resupply spacecraft Dream Chaser to the International Space Station (ISS) under the CRS-2 contract with NASA. The demonstration mission is planned for launch in February 2023 on the second flight of the ULA Vulcan Centaur rocket. Sierra Nevada Corporation (SNC) developed a new reusable spacecraft to provide commercial cargo resupply services to the International Space Station (ISS), based on decades of lifting body programs. Under the Commercial Orbital Transportation System (COTS) program, SNC designed Dream Chaser with industrial partner Lockheed Martin. SNC also designed the accompanying Shooting Star cargo module with subcontractor Applied Composites. At the end of mission, the Shooting Star will destructively reenter the atmosphere and the Dream Chaser will land at the Kennedy Space Center's Shuttle Landing Facility.

References

Notes

Bibliography

- Thomas Heppenheimer, "The Space Shuttle Decision: NASA's Search for a Reusable Space Vehicle", NASA SP-4221, 1999

- George Mueller, "The new future for manned spacecraft developments", Astronautics and Aeronautics, Volume 7 (March 1969), pp. 24–32

- Mark Wade, "Starclipper"