Pottery is the process and the products of forming vessels and other objects with clay and other raw materials, which are fired at high temperatures to give them a hard and durable form. Major types include earthenware, stoneware and porcelain. The place where such wares are made by a potter is also called a pottery. The definition of pottery, used by the ASTM International, is "all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products". In art history and archaeology, especially of ancient and prehistoric periods, pottery often means vessels only, and sculpted figurines of the same material are called terracottas.

Porcelain is a ceramic material made by heating substances, generally including materials such as kaolinite, in a kiln to temperatures between 1,200 and 1,400 °C. The strength and translucence of porcelain, relative to other types of pottery, arises mainly from vitrification and formation of the mineral mullite within the body at these high temperatures. Though definitions vary, porcelain can be divided into three main categories: hard-paste, soft-paste, and bone china. The categories differ by composition of the body and the firing conditions.

Pottery and porcelain, is one of the oldest Japanese crafts and art forms, dating back to the Neolithic period. Kilns have produced earthenware, pottery, stoneware, glazed pottery, glazed stoneware, porcelain, and blue-and-white ware. Japan has an exceptionally long and successful history of ceramic production. Earthenwares were made as early as the Jōmon period, giving Japan one of the oldest ceramic traditions in the world. Japan is further distinguished by the unusual esteem that ceramics holds within its artistic tradition, owing to the enduring popularity of the tea ceremony.

Korean ceramic history begins with the oldest earthenware from around 8000 BC. Throughout the history, the Korean peninsula has been home to lively, innovative, and sophisticated art making. Long period of stability have allowed for the establishment of spiritual traditions, and artisan technologies specific to the region. Korean ceramics in Neolithic period have a unique geometric patterns of sunshine, or it's decorated with twists. In Southern part of Korea, Mumun pottery were popular. Mumun togi used specific minerals to make colors of red and black. Korean pottery developed a distinct style of its own, with its own shapes, such as the moon jar or Buncheong sagi which is a new form between earthenware and porcelain, white clay inlay celadon of Goryeo, and later styles like minimalism that represents Korean Joseon philosophers' idea. Many talented Korean potters were captured and brought to Japan during the invasions of Korea, where they heavily contributed to advancing Japanese pottery. Arita ware, founded by Yi Sam-pyeong opened a new era of porcelain in Japan. Another Japanese representative porcelain, Satsuma ware was also founded by Dang-gil Shim and Pyeong-ui Park. 14th generation of Su-kwan Shim have been using the same name to his grandfather and father to honor they are originally Korean, 14th Su-kwan Shim is honorable citizen of Namwon, Korea.

"Blue and white pottery" covers a wide range of white pottery and porcelain decorated under the glaze with a blue pigment, generally cobalt oxide. The decoration is commonly applied by hand, originally by brush painting, but nowadays by stencilling or by transfer-printing, though other methods of application have also been used. The cobalt pigment is one of the very few that can withstand the highest firing temperatures that are required, in particular for porcelain, which partly accounts for its long-lasting popularity. Historically, many other colours required overglaze decoration and then a second firing at a lower temperature to fix that.

Medieval Islamic pottery occupied a geographical position between Chinese ceramics, the unchallenged leaders of Eurasian production, and the pottery of the Byzantine Empire and Europe. For most of the period it can fairly be said to have been between the two in terms of aesthetic achievement and influence as well, borrowing from China and exporting to and influencing Byzantium and Europe. The use of drinking and eating vessels in gold and silver, the ideal in ancient Rome and Persia as well as medieval Christian societies, is prohibited by the Hadiths, with the result that pottery and glass were used for tableware by Muslim elites, as pottery also was in China but was much rarer in Europe and Byzantium. In the same way, Islamic restrictions greatly discouraged figurative wall-painting, encouraging the architectural use of schemes of decorative and often geometrically patterned titles, which are the most distinctive and original specialty of Islamic ceramics.

Buncheong, or punch'ong, ware is a traditional form of Korean stoneware, with a blue-green tone. Pieces are coated with white slip (ceramics), and decorative designs are added using a variety of techniques. This style originated in the 15th century and continues in a revived form today.

Ding ware, Ting ware or Dingyao are Chinese ceramics, mostly porcelain, that were produced in the prefecture of Dingzhou in Hebei in northern China. The main kilns were at Jiancicun or Jianci in Quyang County. They were produced between the Tang and Yuan dynasties of imperial China, though their finest period was in the 11th century, under the Northern Song. The kilns "were in almost constant operation from the early eighth until the mid-fourteenth century."

Jabez Vodrey (1795–1861) was the first English potter to emigrate to and work west of the Appalachian Mountains in the US.

Mintons was a major company in Staffordshire pottery, "Europe's leading ceramic factory during the Victorian era", an independent business from 1793 to 1968. It was a leader in ceramic design, working in a number of different ceramic bodies, decorative techniques, and "a glorious pot-pourri of styles - Rococo shapes with Oriental motifs, Classical shapes with Medieval designs and Art Nouveau borders were among the many wonderful concoctions". As well as pottery vessels and sculptures, the firm was a leading manufacturer of tiles and other architectural ceramics, producing work for both the Houses of Parliament and United States Capitol.

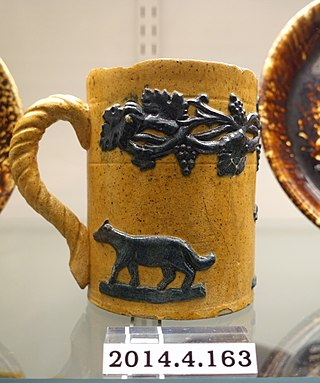

Sprigging or sprigged decoration is a technique for decorating pottery with low relief shapes made separately from the main body and applied to it before firing. Usually thin press moulded shapes are applied to greenware or bisque. The resulting pottery is termed sprigged ware, and the added piece is a "sprig". The technique may also be described by terms such as "applied relief decoration", especially in non-European pottery.

A slip is a clay slurry used to produce pottery and other ceramic wares. Liquified clay, in which there is no fixed ratio of water and clay, is called slip or clay slurry which is used either for joining leather-hard (semi-hardened) clay body together by slipcasting with mould, glazing or decorating the pottery by painting or dipping the pottery with slip. Pottery on which slip has been applied either for glazing or decoration is called the slipware.

This is a list of pottery and ceramic terms.

Tin-glazed pottery is earthenware covered in lead glaze with added tin oxide which is white, shiny and opaque ; usually this provides a background for brightly painted decoration. It has been important in Islamic and European pottery, but very little used in East Asia. The pottery body is usually made of red or buff-colored earthenware and the white glaze imitated Chinese porcelain. The decoration on tin-glazed pottery is usually applied to the unfired glaze surface by brush with metallic oxides, commonly cobalt oxide, copper oxide, iron oxide, manganese dioxide and antimony oxide. The makers of Italian tin-glazed pottery from the late Renaissance blended oxides to produce detailed and realistic polychrome paintings.

The Museum of Ceramics, housed in the former East Liverpool Post Office, is a ceramics museum that contains an extensive collection of ceramic wares produced in and around East Liverpool, Ohio, United States. The museum is operated by a Museum of Ceramics Foundation and by the Ohio Historical Society in a city long known as "America's Crockery City" and "The Pottery Capital of the Nation."

Chinese influences on Islamic pottery cover a period starting from at least the 8th century CE to the 19th century. This influence of Chinese ceramics has to be viewed in the broader context of the considerable importance of Chinese culture on Islamic arts in general.

Cizhou ware or Tz'u-chou ware is a term for a wide range of Chinese ceramics from between the late Tang dynasty and the early Ming dynasty, but especially associated with the Northern Song to Yuan period in the 11–14th century. It has been increasingly realized that a very large number of sites in northern China produced these wares, and their decoration is very variable, but most characteristically uses black and white, in a variety of techniques. For this reason Cizhou-type is often preferred as a general term. All are stoneware in Western terms, and "high-fired" or porcelain in Chinese terms. They were less high-status than other types such as celadons and Jun ware, and are regarded as "popular", though many are finely and carefully decorated.

California pottery includes industrial, commercial, and decorative pottery produced in the Northern California and Southern California regions of the U.S. state of California. Production includes brick, sewer pipe, architectural terra cotta, tile, garden ware, tableware, kitchenware, art ware, figurines, giftware, and ceramics for industrial use. Ceramics include terra cotta, earthenware, porcelain, and stoneware products.

Yellowware, or yellow ware, is a type of earthenware named after its yellow appearance given to it by the clay used for its production. Originating in the United Kingdom in the late 18th century, it was also produced in the eastern United States from the late 1920s.

Ceramic art is art made from ceramic materials, including clay. It may take forms including artistic pottery, including tableware, tiles, figurines and other sculpture. As one of the plastic arts, ceramic art is one of the visual arts. While some ceramics are considered fine art, such as pottery or sculpture, most are considered to be decorative, industrial or applied art objects. Ceramics may also be considered artefacts in archaeology. Ceramic art can be made by one person or by a group of people. In a pottery or ceramic factory, a group of people design, manufacture and decorate the art ware. Products from a pottery are sometimes referred to as "art pottery". In a one-person pottery studio, ceramists or potters produce studio pottery.