The BNC connector is a miniature quick connect/disconnect radio frequency connector used for coaxial cable. It is designed to maintain the same characteristic impedance of the cable, with 50 ohm and 75 ohm types being made. It is usually applied for video and radio frequency connections up to about 2 GHz and up to 500 volts. The connector has a twist to lock design with two lugs in the female portion of the connector engaging a slot in the shell of the male portion. The type was introduced on military radio equipment in the 1940s and has since become widely applied in radio systems, and is a common type of video connector. Similar radio-frequency connectors differ in dimensions and attachment features, and may allow for higher voltages, higher frequencies, or three-wire connections.

Components of an electrical circuit are electrically connected if an electric current can run between them through an electrical conductor. An electrical connector is an electromechanical device used to create an electrical connection between parts of an electrical circuit, or between different electrical circuits, thereby joining them into a larger circuit. Most electrical connectors have a gender – i.e. the male component, called a plug, connects to the female component, or socket. The connection may be removable, require a tool for assembly and removal, or serve as a permanent electrical joint between two points. An adapter can be used to join dissimilar connectors.

The N connector is a threaded, weatherproof, medium-size RF connector used to join coaxial cables. It was one of the first connectors capable of carrying microwave-frequency signals, and was invented in the 1940s by Paul Neill of Bell Labs, after whom the connector is named.

The TNC connector is a threaded version of the BNC connector.

A phone connector, also known as phone jack, audio jack, headphone jack or jack plug, is a family of electrical connectors typically used for analog audio signals. A plug, the male connector, is inserted into the jack, the female connector.

A DC connector is an electrical connector for supplying direct current (DC) power.

The D-subminiature or D-sub is a common type of electrical connector. They are named for their characteristic D-shaped metal shield. When they were introduced, D-subs were among the smallest connectors used on computer systems.

The C connector is a type of RF connector used for terminating coaxial cable. The interface specifications for the C and many other connectors are referenced in MIL-STD-348. The connector uses two-stud bayonet-type locks. The C connector was invented by Amphenol engineer Carl Concelman. It is weatherproof without being overly bulky. The mating arrangement is similar to that of the BNC connector. It can be used up to 11 GHz, and is rated for up to 1500 volts.

SMA connectors are semi-precision coaxial RF connectors developed in the 1960s as a minimal connector interface for coaxial cable with a screw-type coupling mechanism. The connector has a 50 Ω impedance. SMA was originally designed for use from DC (0 Hz) to 12 GHz, however this has been extended over time and variants are available to 18 GHz and 26.5 GHz. There are also mechanically compatible connectors such as the K-connector which operate up to 40 GHz. The SMA connector is most commonly used in microwave systems, hand-held radio and mobile telephone antennas and, more recently, with WiFi antenna systems and USB software-defined radio dongles. It is also commonly used in radio astronomy, particularly at higher frequencies (5 GHz+).

SMC connectors are coaxial RF connectors developed in the 1960s. The interface specifications for the SMC and many other connectors are referenced in MIL-STD-348. They use a #10-32 UNF threaded interface. They offer electrical performance from DC to 10 GHz. Male SMC connectors have a socket for the center contact, and Female SMC connectors have a pin for the center contact. SMC jack connectors have an external thread while SMC plug connectors have the mating hex nut. Available in 50-Ohm and 75-Ohm characteristic impedance, they provide an interconnect means for small form factor coaxial cables and printed circuit boards where small footprint is important.

A United States defense standard, often called a military standard, "MIL-STD", "MIL-SPEC", or (informally) "MilSpecs", is used to help achieve standardization objectives by the U.S. Department of Defense.

The UHF connector is a name for a threaded RF connector. The connector design was invented in the 1930s for use in the radio industry, and is a shielded form of the "banana plug". It is a widely used standard connector for HF transmission lines on full-sized radio equipment, with BNC connectors predominating for smaller, hand-held equipment.

The term Amphenol connector refers to various electronics connectors that are introduced, or made primarily by Amphenol Corp. Depending on the area of electronics concerned, it may refer specifically to:

EIA RF Connectors are used to connect two items of high power radio frequency rigid or semi-rigid (flexline) coaxial transmission line. Typically these are only required in very high power transmitting installations where the feedline diameters may be several inches. The connectors are always female, requiring a male coupling element or bullet to make the connection. The EIA under the Electronic Components Industry Association, are responsible for a number of standard imperial connector sizes.

JIC fittings, defined by the SAE J514 and MIL-DTL-18866 standards, are a type of flare fitting machined with a 37-degree flare seating surface. JIC fittings are widely used in fuel delivery and fluid power applications, especially where high pressure is involved. The SAE J514 standard replaces the MS16142 military specification, although some tooling is still listed under MS16142. JIC fittings are dimensionally identical to AN (Army-Navy) fittings, but are produced to less exacting tolerances and are generally less costly. SAE 45-degree flare fittings are similar in appearance, but are not interchangeable, though dash sizes 2, 3, 4, 5, 8, and 10 share the same thread size. Some couplings may have dual machined seats for both 37-degree and 45-degree flare seats. Komatsu and JIS fittings have flare ends similar to JIC fittings. Komatsu and JIS both use a 30-degree flare seating surface. The only difference is Komatsu uses millimeter thread sizes while JIS use a BSP thread. JIC fitting systems have three components that make a tubing assembly: fitting, flare nut, and sleeve. As with other flared connection systems, the seal is achieved through metal-to-metal contact between the finished surface of the fitting nose and the inside diameter of the flared tubing. The sleeve is used to evenly distribute the compressive forces of the flare nut to the flared end of the tube. Materials commonly used to fabricate JIC fittings include forged carbon steel, forged stainless steel, forged brass, machined brass, Monel and nickel-copper alloys.

Electrical or fiber-optic connectors used by U.S. Department of Defense were originally developed in the 1930s for severe aeronautical and tactical service applications, and the Type "AN" (Army-Navy) series set the standard for modern military circular connectors. These connectors, and their evolutionary derivatives, are often called Military Standard, "MIL-STD", or (informally) "MIL-SPEC" or sometimes "MS" connectors. They are now used in aerospace, industrial, marine, and even automotive commercial applications.

A concentric twinax connector has a center pin and a cylindrical intermediate contact as compared to a dual polarized pin type.

An electrical crimp is a type of solderless electrical connection.

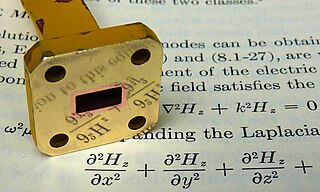

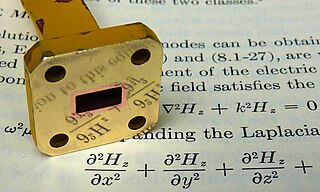

A waveguide flange is a connector for joining sections of waveguide, and is essentially the same as a pipe flange—a waveguide, in the context of this article, being a hollow metal conduit for microwave energy. The connecting face of the flange is either square, circular or, rectangular. The connection between a pair of flanges is usually made with four or more bolts, though alternative mechanisms, such as a threaded collar, may be used where there is a need for rapid assembly and disassembly. Dowel pins are sometimes used in addition to bolts, to ensure accurate alignment, particularly for very small waveguides.

FASTON terminals are connectors that are widely used in electronic and electrical equipment. These terminals are manufactured by many companies, commonly using the term "quick disconnect", "tab" terminals, or blade connectors.