Related Research Articles

A clutch is a mechanical device that allows the output shaft to be disconnected from the rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does the work.

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft. An electric generator is mechanically identical to an electric motor, but operates with a reversed flow of power, converting mechanical energy into electrical energy.

A stepper motor, also known as step motor or stepping motor, is a brushless DC electric motor that divides a full rotation into a number of equal steps. The motor's position can be commanded to move and hold at one of these steps without any position sensor for feedback, as long as the motor is correctly sized to the application in respect to torque and speed.

A continuously variable transmission (CVT) is an automatic transmission that can change through a continuous range of gear ratios. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant RPM while the vehicle moves at varying speeds.

A brushless DC electric motor (BLDC), also known as an electronically commutated motor, is a synchronous motor using a direct current (DC) electric power supply. It uses an electronic controller to switch DC currents to the motor windings producing magnetic fields that effectively rotate in space and which the permanent magnet rotor follows. The controller adjusts the phase and amplitude of the DC current pulses to control the speed and torque of the motor. This control system is an alternative to the mechanical commutator (brushes) used in many conventional electric motors.

A limited-slip differential (LSD) is a type of differential that allows its two output shafts to rotate at different speeds but limits the maximum difference between the two shafts. Limited-slip differentials are often known by the generic trademark Positraction, a brand name owned by General Motors and originally used for its Chevrolet branded vehicles.

A DC motor is an electrical motor that uses direct current (DC) to produce mechanical force. The most common types rely on magnetic forces produced by currents in the coils. Nearly all types of DC motors have some internal mechanism, either electromechanical or electronic, to periodically change the direction of current in part of the motor.

A dynamometer or "dyno" for short, is a device for simultaneously measuring the torque and rotational speed (RPM) of an engine, motor or other rotating prime mover so that its instantaneous power may be calculated, and usually displayed by the dynamometer itself as kW or bhp.

Torsional vibration is the angular vibration of an object - commonly a shaft - along its axis of rotation. Torsional vibration is often a concern in power transmission systems using rotating shafts or couplings, where it can cause failures if not controlled. A second effect of torsional vibrations applies to passenger cars. Torsional vibrations can lead to seat vibrations or noise at certain speeds. Both reduce the comfort.

A linear actuator is an actuator that creates motion in a straight line, in contrast to the circular motion of a conventional electric motor. Linear actuators are used in machine tools and industrial machinery, in computer peripherals such as disk drives and printers, in valves and dampers, and in many other places where linear motion is required. Hydraulic or pneumatic cylinders inherently produce linear motion. Many other mechanisms are used to generate linear motion from a rotating motor.

The universal motor is a type of electric motor that can operate on either AC or DC power and uses an electromagnet as its stator to create its magnetic field. It is a commutated series-wound motor where the stator's field coils are connected in series with the rotor windings through a commutator. It is often referred to as an AC series motor. The universal motor is very similar to a DC series motor in construction, but is modified slightly to allow the motor to operate properly on AC power. This type of electric motor can operate well on AC because the current in both the field coils and the armature will alternate synchronously with the supply. Hence the resulting mechanical force will occur in a consistent direction of rotation, independent of the direction of applied voltage, but determined by the commutator and polarity of the field coils.

Motor drive means a system that includes a motor. An adjustable speed motor drive means a system that includes a motor that has multiple operating speeds. A variable speed motor drive is a system that includes a motor and is continuously variable in speed. If the motor is generating electrical energy rather than using it – this could be called a generator drive but is often still referred to as a motor drive.

An AC motor is an electric motor driven by an alternating current (AC). The AC motor commonly consists of two basic parts, an outside stator having coils supplied with alternating current to produce a rotating magnetic field, and an inside rotor attached to the output shaft producing a second rotating magnetic field. The rotor magnetic field may be produced by permanent magnets, reluctance saliency, or DC or AC electrical windings.

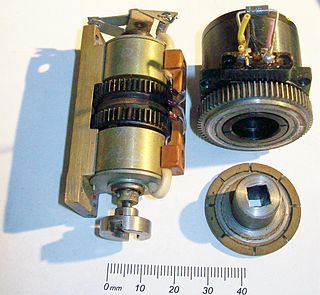

Electromagnetic clutches operate electrically but transmit torque mechanically. This is why they used to be referred to as electro-mechanical clutches. Over the years, EM became known as electromagnetic versus electro-mechanical, referring more about their actuation method versus physical operation. Since the clutches started becoming popular over 60 years ago, the variety of applications and clutch designs has increased dramatically, but the basic operation remains the same today.

A brushed DC electric motor is an internally commutated electric motor designed to be run from a direct current power source and utilizing an electric brush for contact.

Electromagnetic brakes or EM brakes are used to slow or stop vehicles using electromagnetic force to apply mechanical resistance (friction). They were originally called electro-mechanical brakes but over the years the name changed to "electromagnetic brakes", referring to their actuation method which is generally unrelated to modern electro-mechanical brakes. Since becoming popular in the mid-20th century, especially in trains and trams, the variety of applications and brake designs has increased dramatically, but the basic operation remains the same.

In electrical engineering, electric machine is a general term for machines using electromagnetic forces, such as electric motors, electric generators, and others. They are electromechanical energy converters: an electric motor converts electricity to mechanical power while an electric generator converts mechanical power to electricity. The moving parts in a machine can be rotating or linear. Besides motors and generators, a third category often included is transformers, which although they do not have any moving parts are also energy converters, changing the voltage level of an alternating current.

The Hele-Shaw clutch was an early form of multi-plate wet clutch, in use around 1900. It was named after its inventor, Professor Henry Selby Hele-Shaw, who was noted for his work in viscosity and flows through small gaps between parallel plates. The clutch was innovative in not relying upon friction, as other clutches did.

Electromagnetic clutches and brakes operate electrically, but transmit torque mechanically. This is why they used to be referred to as electro-mechanical clutches or brakes. Over the years, EM became known as electromagnetic versus electro mechanical, referring more about their actuation method versus physical operation. Since the clutches started becoming popular over 60 years ago, the variety of applications and brake and clutch designs has increased dramatically, but the basic operation remains the same.

A torque amplifier is a mechanical device that amplifies the torque of a rotating shaft without affecting its rotational speed. It is mechanically related to the capstan seen on ships. Its most widely known use is in power steering on automobiles. Another use is on the differential analyser, where it was used to increase the output torque of the otherwise limited ball-and-disk integrator. The term is also applied to some gearboxes used on tractors, although this is unrelated. It differs from a torque converter, in which the rotational speed of the output shaft decreases as the torque increases.

References

- ↑ "Electromagnetic Particle Clutch". ogura-clutch.com. Archived from the original on 2019-05-25. Retrieved 2019-02-14.

- ↑ "How Magnetic Particle Clutches Work". Placid Industries. Archived from the original on 2020-09-28. Retrieved 2019-02-14.