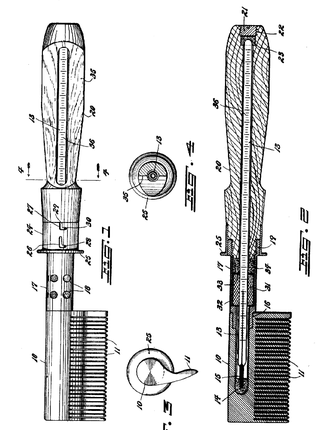

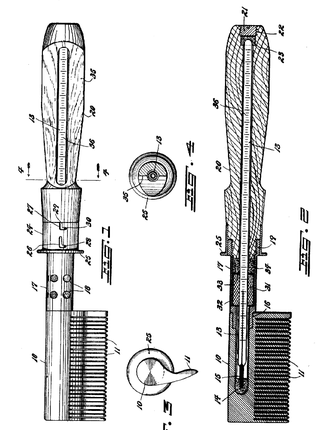

A soldering iron is a hand tool used in soldering. It supplies heat to melt solder so that it can flow into the joint between two workpieces.

Heat treating is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term heat treatment applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding.

A clothes dryer is a powered household appliance that is used to remove moisture from a load of clothing, bedding and other textiles, usually after they are washed in the washing machine.

A Dutch oven, Dutch pot, or casserole dish (international) is a thick-walled cooking pot with a tight-fitting lid. Dutch ovens are usually made of seasoned cast iron; however, some Dutch ovens are instead made of cast aluminium, or ceramic. Some metal varieties are enameled rather than being seasoned, and these are sometimes called French ovens. The international name casserole dish is from the French casserole which means "cooking pot". They are similar to both the Japanese tetsunabe and the sač, a traditional Balkan cast-iron oven, and are related to the South African potjie, the Australian Bedourie oven and Spanish cazuela.

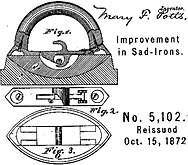

A clothes iron is a small appliance that, when heated, is used to press clothes to remove wrinkles and unwanted creases. Domestic irons generally range in operating temperature from between 121 °C (250 °F) to 182 °C (360 °F). It is named for the metal (iron) of which the device was historically made, and the use of it is generally called ironing, the final step in the process of laundering clothes.

A branding iron is used for branding, pressing a heated metal shape against an object or livestock with the intention of leaving an identifying mark.

A hair iron or hair tong is a tool used to change the arrangement of the hair using heat. There are three general kinds: curling irons, used to make the hair curl; straightening irons, commonly called straighteners or flat irons, used to straighten the hair; and crimping irons, used to create crimps of the desired size in the hair.

A mangle is a mechanical laundry aid consisting of two rollers in a sturdy frame, connected by cogs and powered by a hand crank or by electricity.

A jack plane is a general-purpose woodworking bench plane, used for dressing timber down to size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but for rougher work it can be preceded by the scrub plane. The versatility of the jack plane has led to it being the most common bench plane in use. The name jack plane is sometimes used interchangeably with the longer fore plane.

A waffle iron or waffle maker is a kitchen utensil used to cook waffles between two hinged metal plates. Both plates have gridded indentations to shape the waffle from the batter or dough placed between them. The plates are heated and the iron is closed while the waffle bakes. Waffles are a quick bread with a light and sweet flavor, similar to pancakes. Their appearance is much harder to achieve than a pancake's without a waffle iron. Similar technology is employed to bake wafers, and several other snacks including kue gapit, a waffle-shaped but crunchy Indonesian snack which can be made with both sweet and savoury flavours.

A Hills Hoist is a height-adjustable rotary clothes line, designed to permit the compact hanging of wet clothes so that their maximum area can be exposed for wind drying by rotation. They are considered one of Australia's most recognisable icons, and are used frequently by artists as a metaphor for Australian suburbia in the 1950s and 1960s.

A hot comb is a metal comb that is used to straighten moderate or coarse hair and create a smoother hair texture. A hot comb is heated and used to straighten the hair from the roots. It can be placed directly on the source of heat or it may be electrically heated.

A tinsmith is a person who makes and repairs things made of tin or other light metals. The profession may sometimes also be known as a tinner, tinker, tinman, or tinplate worker; whitesmith may also refer to this profession, though the same word may also refer to an unrelated specialty of iron-smithing. By extension it can also refer to the person who deals in tinware, or tin plate. Tinsmith was a common occupation in pre-industrial times.

A kitchen utensil is a small hand-held tool used for food preparation. Common kitchen tasks include cutting food items to size, heating food on an open fire or on a stove, baking, grinding, mixing, blending, and measuring; different utensils are made for each task. A general purpose utensil such as a chef's knife may be used for a variety of foods; other kitchen utensils are highly specialized and may be used only in connection with preparation of a particular type of food, such as an egg separator or an apple corer. Some specialized utensils are used when an operation is to be repeated many times, or when the cook has limited dexterity or mobility. The number of utensils in a household kitchen varies with time and the style of cooking.

Austempering is heat treatment that is applied to ferrous metals, most notably steel and ductile iron. In steel it produces a bainite microstructure whereas in cast irons it produces a structure of acicular ferrite and high carbon, stabilized austenite known as ausferrite. It is primarily used to improve mechanical properties or reduce / eliminate distortion. Austempering is defined by both the process and the resultant microstructure. Typical austempering process parameters applied to an unsuitable material will not result in the formation of bainite or ausferrite and thus the final product will not be called austempered. Both microstructures may also be produced via other methods. For example, they may be produced as-cast or air cooled with the proper alloy content. These materials are also not referred to as austempered.

A folding table is a type of folding furniture, a table with legs that fold up against the table top. This is intended to make storage more convenient and to make the table more portable. Many folding tables are made of lightweight materials to further increase portability.

Heated shot or hot shot is round shot that is heated before firing from muzzle-loading cannons, for the purpose of setting fire to enemy warships, buildings, or equipment. The use of heated shot dates back centuries. It was a powerful weapon against wooden warships, where fire was always a hazard. It was rendered obsolete in the mid-19th century when vessels armored with iron replaced wooden warships in the world's navies. Also at around the same time, the replacement of solid-iron shot with exploding shells gave artillery a far more destructive projectile that could be fired immediately without preparation.

Ironing is the use of an iron, usually heated, to remove wrinkles and unwanted creases from fabric. The heating is commonly done to a temperature of 180–220 °C (360–430 °F), depending on the fabric. Ironing works by loosening the bonds between the long-chain polymer molecules in the fibres of the material. While the molecules are hot, the fibres are straightened by the weight of the iron, and they hold their new shape as they cool. Some fabrics, such as cotton, require the addition of water to loosen the intermolecular bonds. Many modern fabrics are advertised as needing little or no ironing. Permanent press clothing was developed to reduce the ironing necessary by combining wrinkle-resistant polyester with cotton.

The United States provided many inventions in the time from the Colonial Period to the Gilded Age, which were achieved by inventors who were either native-born or naturalized citizens of the United States. Copyright protection secures a person's right to his or her first-to-invent claim of the original invention in question, highlighted in Article I, Section 8, Clause 8 of the United States Constitution, which gives the following enumerated power to the United States Congress:

To promote the Progress of Science and useful Arts, by securing for limited Times to Authors and Inventors the exclusive Right to their respective Writings and Discoveries.

The "Scope" soldering iron is a tool for soldering with lead-tin alloys, made in Australia since 1950, and intended for occasional or intermittent use. It has the virtue of quickly coming up to soldering temperature (~300C) and delivering considerable heat to a small area, but requires care to avoid overheating. It operates on low voltage and high current from a battery or suitable transformer, so is by design electrically safe, and as it cools down rapidly when it leaves the operator's hand, should not constitute a fire risk.