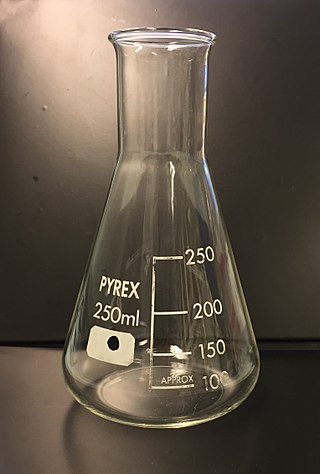

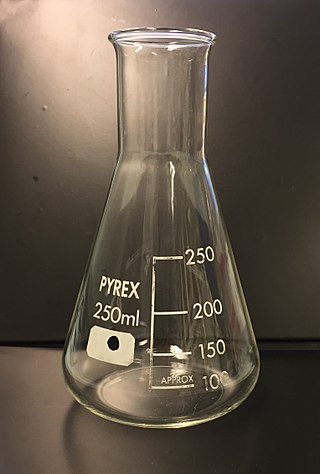

An Erlenmeyer flask, also known as a conical flask or a titration flask, is a type of laboratory flask which features a flat bottom, a conical body, and a cylindrical neck. It is most often used in a laboratory. It is named after the German chemist Emil Erlenmeyer (1825–1909), who created it in 1860.

In viscous fluid dynamics, the Archimedes number (Ar), is a dimensionless number used to determine the motion of fluids due to density differences, named after the ancient Greek scientist and mathematician Archimedes.

A bioreactor refers to any manufactured device or system that supports a biologically active environment. In one case, a bioreactor is a vessel in which a chemical process is carried out which involves organisms or biochemically active substances derived from such organisms. This process can either be aerobic or anaerobic. These bioreactors are commonly cylindrical, ranging in size from litres to cubic metres, and are often made of stainless steel. It may also refer to a device or system designed to grow cells or tissues in the context of cell culture. These devices are being developed for use in tissue engineering or biochemical/bioprocess engineering.

In organic chemistry, hydroformylation, also known as oxo synthesis or oxo process, is an industrial process for the production of aldehydes from alkenes. This chemical reaction entails the net addition of a formyl group and a hydrogen atom to a carbon-carbon double bond. This process has undergone continuous growth since its invention: production capacity reached 6.6×106 tons in 1995. It is important because aldehydes are easily converted into many secondary products. For example, the resultant aldehydes are hydrogenated to alcohols that are converted to detergents. Hydroformylation is also used in speciality chemicals, relevant to the organic synthesis of fragrances and pharmaceuticals. The development of hydroformylation is one of the premier achievements of 20th-century industrial chemistry.

See Patented via Nth Cycle for metal electro-extraction process.

Jürgen Gmehling is a retired German professor of technical and industrial chemistry at the Carl von Ossietzky University of Oldenburg.

Product inhibition is a type of enzyme inhibition where the product of an enzyme reaction inhibits its production. Cells utilize product inhibition to regulate of metabolism as a form of negative feedback controlling metabolic pathways. Product inhibition is also an important topic in biotechnology, as overcoming this effect can increase the yield of a product, such as an antibiotic. Product inhibition can be Competitive, non-competitive or uncompetitive.

Viktor Vasilyevich Dilman, also spelled Dil'man is a Russian scientist performing research for USPolyResearch. He is best known for his work in chemical engineering and hydrodynamics including the approximate methods for solving nonlinear differential equations of mass, heat, and momentum transfer; mathematical modeling of chemical reactor processes and catalytic distillation; heat, mass, and momentum transfer in turbulent flow; fluid dynamics in granular beds; surface convection, absorption, and molecular convection.

A microcarrier is a support matrix that allows for the growth of adherent cells in bioreactors. Instead of on a flat surface, cells are cultured on the surface of spherical microcarriers so that each particle carries several hundred cells, and therefore expansion capacity can be multiplied several times over. It provides a straightforward way to scale up culture systems for industrial production of cell or protein-based therapies, or for research purposes.

Membrane bioreactors are combinations of some membrane processes like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. These technologies are now widely used for municipal and industrial wastewater treatment. The two basic membrane bioreactor configurations are the submerged membrane bioreactor and the side stream membrane bioreactor. In the submerged configuration, the membrane is located inside the biological reactor and submerged in the wastewater, while in a side stream membrane bioreactor, the membrane is located outside the reactor as an additional step after biological treatment.

Martinus (Tinus) Tels was a Dutch physicist and chemical engineer. He was a professor of chemical engineering, dean of the department of chemical engineering and the ninth rector magnificus of the Eindhoven University of Technology.

This bibliography of Rutherford Aris contains a comprehensive listing of the scientific publications of Aris, including books, journal articles, and contributions to other published material.

Andrzej Górak is a Polish process engineer and the Head of Laboratory of Fluid Separations at the Department of Biochemical and Chemical Engineering at the TU Dortmund University.

John A. Quinn was the Robert D. Bent Professor Emeritus of Chemical and Biomolecular Engineering at the University of Pennsylvania School of Engineering and Applied Science. He was a leader in the fields of mass transfer and membrane transport in synthetic membranes since the 1960s. In the early phase of his career at the University of Illinois, Quinn and his students devised simple, elegant experiments to elucidate the role of the interface in mass transfer between phases. In later work at Penn, he applied these insights to problems of engineering and biological significance involving chemical reaction and diffusion within and through both finely porous and reactive membranes. His chemical engineering science has informed matters as far afield as the separation of chiral pharmaceuticals and the behavior of cells at interfaces.

Jyeshtharaj Bhalchandra Joshi is an Indian chemical engineer, nuclear scientist, consultant and professor, widely known for his innovations in nuclear reactor designs and generally regarded as a respected teacher. He is the DAE-Homi Bhabha Chair Professor, Homi Bhabha National Institute, Mumbai, and is the recipient of Shantiswarup Bhatnagar Prize for Engineering Sciences and many other awards and recognitions. He received the third highest civilian honour, the Padma Bhushan, in 2014 for his services to the field of chemical engineering and nuclear science.

Nediljko "Ned" Budisa is a Croatian biochemist, professor and holder of the Tier 1 Canada Research Chair (CRC) for chemical synthetic biology at the University of Manitoba. As pioneer in the areas of genetic code engineering and chemical synthetic biology (Xenobiology), his research has a wide range of applications in biotechnology and engineering biology in general. Being highly interdisciplinary, it includes bioorganic and medical chemistry, structural biology, biophysics and molecular biotechnology as well as metabolic and biomaterial engineering. He is the author of the only textbook in his research field: “Engineering the genetic code: expanding the amino acid repertoire for the design of novel proteins”.

Liquid organic hydrogen carriers (LOHC) are organic compounds that can absorb and release hydrogen through chemical reactions. LOHCs can therefore be used as storage media for hydrogen. In principle, every unsaturated compound can take up hydrogen during hydrogenation. The sequence of endothermal dehydrogenation followed by hydrogen purification is considered as the main drawback which limits the overall efficiency of the storage cycle. LOHC shipping without heat recycling has an energy efficiency of 60-70%, depending on the dehydrogenation rate, which is equivalent to liquid hydrogen shipping. With heat recycling, the energy efficiency increase to 80-90%.

Regina Palkovits is a German chemist who is a Professor of Chemistry at the RWTH Aachen University. Her research considers heterogenous catalysis. She was elected a Fellow of the North Rhine-Westphalian Academy of Sciences, Humanities and the Arts in 2020.

ms2 is a non-commercial molecular simulation program. It comprises both molecular dynamics and Monte Carlo simulation algorithms. ms2 is designed for the calculation of thermodynamic properties of fluids. A large number of thermodynamic properties can be readily computed using ms2, e.g. phase equilibrium, transport and caloric properties. ms2 is limited to homogeneous state simulations.

The Cluster of Excellence Unifying Systems in Catalysis (UniSysCat) is an interdisciplinary research network funded by the German Research Foundation (DFG) as a part of the federal and state excellence strategy of Germany, Exzellenzstrategie. The funding period runs from January 1, 2019 to December 31, 2025. Around 300 researchers from the Berlin and Potsdam area work in UniSysCat, focusing on current issues in catalysis research. UniSysCat is the follow-up project of the Cluster of Excellence Unifying Concepts in Catalysis (UniCat), which was funded from 2007 to 2018 as part of the federal and state excellence initiative of Germany Exzellenzinitiative.