Related Research Articles

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing a nonmetallic mineral, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick.

Young's modulus, the Young modulus, or the modulus of elasticity in tension, is a mechanical property that measures the tensile stiffness of a solid material. It quantifies the relationship between tensile stress and axial strain in the linear elastic region of a material and is determined using the formula:

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials the ultimate tensile strength is close to the yield point, whereas in ductile materials the ultimate tensile strength can be higher.

In engineering and materials science, a stress–strain curve for a material gives the relationship between stress and strain. It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress and strain can be determined. These curves reveal many of the properties of a material, such as the Young's modulus, the yield strength and the ultimate tensile strength.

The field of strength of materials, also called mechanics of materials, typically refers to various methods of calculating the stresses and strains in structural members, such as beams, columns, and shafts. The methods employed to predict the response of a structure under loading and its susceptibility to various failure modes takes into account the properties of the materials such as its yield strength, ultimate strength, Young's modulus, and Poisson's ratio. In addition, the mechanical element's macroscopic properties such as its length, width, thickness, boundary constraints and abrupt changes in geometry such as holes are considered.

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing. One definition of material toughness is the amount of energy per unit volume that a material can absorb before rupturing. This measure of toughness is different from that used for fracture toughness, which describes load bearing capabilities of materials with flaws. It is also defined as a material's resistance to fracture when stressed.

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture.

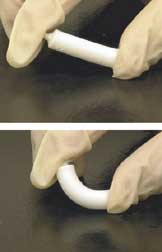

Work hardening, also known as strain hardening, is the strengthening of a metal or polymer by plastic deformation. Work hardening may be desirable, undesirable, or inconsequential, depending on the context.

Titanium alloys are alloys that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness. They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. However, the high cost of both raw materials and processing limit their use to military applications, aircraft, spacecraft, bicycles, medical devices, jewelry, highly stressed components such as connecting rods on expensive sports cars and some premium sports equipment and consumer electronics.

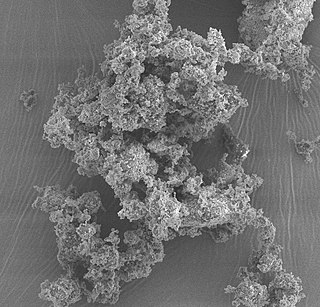

Bioglass 45S5 or calcium sodium phosphosilicate, commonly referred to by its commercial name Bioglass and NovaMin, is a glass specifically composed of 45 wt% SiO2, 24.5 wt% CaO, 24.5 wt% Na2O, and 6.0 wt% P2O5. Glasses are non-crystalline amorphous solids that are commonly composed of silica-based materials with other minor additives. Compared to soda-lime glass (commonly used, as in windows or bottles), Bioglass 45S5 contains less silica and higher amounts of calcium and phosphorus. The 45S5 name signifies glass with 45 weight % of SiO2 and 5:1 molar ratio of calcium to phosphorus. This high ratio of calcium to phosphorus promotes formation of apatite crystals; calcium and silica ions can act as crystallization nuclei. Lower Ca:P ratios do not bond to bone. Bioglass 45S5's specific composition is optimal in biomedical applications because of its similar composition to that of hydroxyapatite, the mineral component of bone. This similarity provides Bioglass' ability to be integrated with living bone.

Bioactive glasses are a group of surface reactive glass-ceramic biomaterials and include the original bioactive glass, Bioglass. The biocompatibility and bioactivity of these glasses has led them to be investigated extensively for use as implant devices in the human body to repair and replace diseased or damaged bones.

In materials science, fracture toughness is the critical stress intensity factor of a sharp crack where propagation of the crack suddenly becomes rapid and unlimited. A component's thickness affects the constraint conditions at the tip of a crack with thin components having plane stress conditions and thick components having plane strain conditions. Plane strain conditions give the lowest fracture toughness value which is a material property. The critical value of stress intensity factor in mode I loading measured under plane strain conditions is known as the plane strain fracture toughness, denoted . When a test fails to meet the thickness and other test requirements that are in place to ensure plane strain conditions, the fracture toughness value produced is given the designation . Fracture toughness is a quantitative way of expressing a material's resistance to crack propagation and standard values for a given material are generally available.

Hardness is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion. In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as sodium and metallic tin, or wood and common plastics. Macroscopic hardness is generally characterized by strong intermolecular bonds, but the behavior of solid materials under force is complex; therefore, there are different measurements of hardness: scratch hardness, indentation hardness, and rebound hardness.

A biomaterial is a substance that has been engineered to interact with biological systems for a medical purpose, either a therapeutic or a diagnostic one. As a science, biomaterials is about fifty years old. The study of biomaterials is called biomaterials science or biomaterials engineering. It has experienced steady and strong growth over its history, with many companies investing large amounts of money into the development of new products. Biomaterials science encompasses elements of medicine, biology, chemistry, tissue engineering and materials science.

Filler materials are particles added to resin or binders that can improve specific properties, make the product cheaper, or a mixture of both. The two largest segments for filler material use is elastomers and plastics. Worldwide, more than 53 million tons of fillers are used every year in application areas such as paper, plastics, rubber, paints, coatings, adhesives, and sealants. As such, fillers, produced by more than 700 companies, rank among the world's major raw materials and are contained in a variety of goods for daily consumer needs. The top filler materials used are ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), kaolin, talc, and carbon black. Filler materials can affect the tensile strength, toughness, heat resistance, color, clarity etc. A good example of this is the addition of talc to polypropylene. Most of the filler materials used in plastics are mineral or glass based filler materials. Particulates and fibers are the main subgroups of filler materials. Particulates are small particles of filler which are mixed in the matrix where size and aspect ratio are important. Fibers are small circular strands that can be very long and have very high aspect ratios.

Bioceramics and bioglasses are ceramic materials that are biocompatible. Bioceramics are an important subset of biomaterials. Bioceramics range in biocompatibility from the ceramic oxides, which are inert in the body, to the other extreme of resorbable materials, which are eventually replaced by the body after they have assisted repair. Bioceramics are used in many types of medical procedures. Bioceramics are typically used as rigid materials in surgical implants, though some bioceramics are flexible. The ceramic materials used are not the same as porcelain type ceramic materials. Rather, bioceramics are closely related to either the body's own materials or are extremely durable metal oxides.

Artificial bone refers to bone-like material created in a laboratory that can be used in bone grafts, to replace human bone that was lost due to severe fractures, disease, etc.

Mechanical testing covers a wide range of tests, which can be divided broadly into two types:

- those that aim to determine a material's mechanical properties, independent of geometry.

- those that determine the response of a structure to a given action, e.g. testing of composite beams, aircraft structures to destruction, etc.

Polymer fracture is the study of the fracture surface of an already failed material to determine the method of crack formation and extension in polymers both fiber reinforced and otherwise. Failure in polymer components can occur at relatively low stress levels, far below the tensile strength because of four major reasons: long term stress or creep rupture, cyclic stresses or fatigue, the presence of structural flaws and stress-cracking agents. Formations of submicroscopic cracks in polymers under load have been studied by x ray scattering techniques and the main regularities of crack formation under different loading conditions have been analyzed. The low strength of polymers compared to theoretically predicted values are mainly due to the many microscopic imperfections found in the material. These defects namely dislocations, crystalline boundaries, amorphous interlayers and block structure can all lead to the non-uniform distribution of mechanical stress.

References

- 1 2 3 4 Katti, K. S. (2004). Biomaterials in total joint replacement. Colloids and Surfaces B: Biointerfaces, 39(3), 133-142.

- ↑ Wang, R. Z., Cui, F. Z., Lu, H. B., Wen, H. B., Ma, C. L., & Li, H. D. (1995). Synthesis of nanophase hydroxyapatite/collagen composite. Journal of materials science letters, 14(7), 490-492.

- 1 2 3 Kokubo, T. (Ed.). (2008). Bioceramics and their clinical applications. Woodhead Pub. and Maney Pub.

- ↑ Fischer, H., & Marx, R. (2002). Fracture toughness of dental ceramics: comparison of bending and indentation method. Dental Materials, 18(1), 12-19.

- 1 2 3 4 Chen, Q., Zhu, C., & Thouas, G. A. (2012). Progress and challenges in biomaterials used for bone tissue engineering: bioactive glasses and elastomeric composites. Progress in Biomaterials, 1(1), 1-22.

- 1 2 3 4 5 6 7 8 Amaral, M., Lopes, M. A., Silva, R. F., & Santos, J. D. (2002). Densification route and mechanical properties of Si 3 N 4–bioglass biocomposites. Biomaterials, 23(3), 857-862.

- 1 2 Kokubo, T., Kim, H. M., & Kawashita, M. (2003). Novel bioactive materials with different mechanical properties. Biomaterials, 24(13), 2161-2175.

- 1 2 3 4 5 6 Niinomi, M. (1998). Mechanical properties of biomedical titanium alloys.Materials Science and Engineering: A, 243(1), 231-236.

- 1 2 3 4 5 6 7 "Archived copy". Archived from the original on 2013-10-30. Retrieved 2013-05-03.CS1 maint: archived copy as title (link)

1)Ichim, Q. Li, W. Li, M.V. Swain, J. Kieser,Modelling of fracture behaviour in biomaterials,Biomaterials,Volume 28, Issue 7,2007,Pages 1317-1326

2)S.H Teoh, Fatigue of biomaterials: a review, International Journal of Fatigue, Volume 22, Issue 10, 2000, Pages 825-837