A micrometer, sometimes known as a micrometer screw gauge, is a device incorporating a calibrated screw widely used for accurate measurement of components in mechanical engineering and machining as well as most mechanical trades, along with other metrological instruments such as dial, vernier, and digital calipers. Micrometers are usually, but not always, in the form of calipers. The spindle is a very accurately machined screw and the object to be measured is placed between the spindle and the anvil. The spindle is moved by turning the ratchet knob or thimble until the object to be measured is lightly touched by both the spindle and the anvil.

A mechanical or physical shock is a sudden acceleration caused, for example, by impact, drop, kick, earthquake, or explosion. Shock is a transient physical excitation.

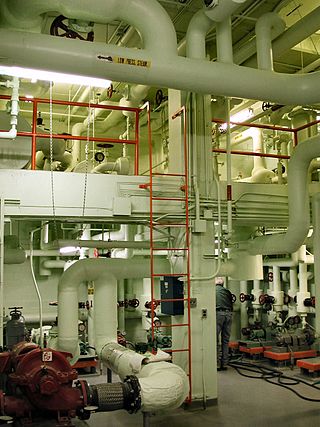

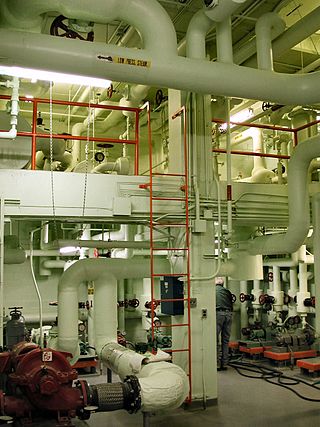

A fire sprinkler system is an active fire protection method, consisting of a water supply system providing adequate pressure and flowrate to a water distribution piping system, to which fire sprinklers are connected. Although initially used only in factories and large commercial buildings, systems for homes and small buildings are now available at a cost-effective price.

An actuator is a component of a machine that is responsible for moving and controlling a mechanism or system, for example by opening a valve. In simple terms, it is a "mover".

An accelerometer is a tool that measures proper acceleration. Proper acceleration is the acceleration of a body in its own instantaneous rest frame; this is different from coordinate acceleration, which is acceleration in a fixed coordinate system. For example, an accelerometer at rest on the surface of the Earth will measure an acceleration due to Earth's gravity, straight upwards of g ≈ 9.81 m/s2. By contrast, accelerometers in free fall will measure zero.

A turnbuckle, stretching screw or bottlescrew is a device for adjusting the tension or length of ropes, cables, tie rods, and other tensioning systems. It normally consists of two threaded eye bolts, one screwed into each end of a small metal frame, one with a left-hand thread and the other with a right-hand thread. The tension can be adjusted by rotating the frame, which causes both eye bolts to be screwed in or out simultaneously, without twisting the eye bolts or attached cables.

Within industry, piping is a system of pipes used to convey fluids from one location to another. The engineering discipline of piping design studies the efficient transport of fluid.

A snubber is a device used to suppress a phenomenon such as voltage transients in electrical systems, pressure transients in fluid systems or excess force or rapid movement in mechanical systems.

In pipeline transportation, pigging is the practice of using pipeline inspection gauges or gadgets, devices generally referred to as pigs or scrapers, to perform various maintenance operations. This is done without stopping the flow of the product in the pipeline.

This is an alphabetical list of articles pertaining specifically to mechanical engineering. For a broad overview of engineering, please see List of engineering topics. For biographies please see List of engineers.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

An earthquake valve is an automatic method to shut off the low pressure regulated gas supply to a structure during a major earthquake and/or if a pipe is broken. These are applicable both to utility-supplied natural gas and to gas from liquefied petroleum gas (LPG). These small devices are installed on the property gas meter and are designed to instantly stop the natural gas supply in order to protect the structure if a gas leak or line break occurs during an earthquake.

MinebeaMitsumi, Inc. is a Japanese multinational corporation and a major producer of machinery components and electronics devices. The company was founded as Minebea Co., Ltd. in 1951. As of June 30, 2019, MinebeaMitsumi comprises 121 consolidated subsidiaries and affiliates. NMB (USA) Inc. is an American holding company that manages Minebea's American subsidiaries.

Acoustic quieting is the process of making machinery quieter by damping vibrations to prevent them from reaching the observer. Machinery vibrates, causing sound waves in air, hydroacoustic waves in water, and mechanical stresses in solid matter. Quieting is achieved by absorbing the vibrational energy or minimizing the source of the vibration. It may also be redirected away from the observer.

In earthquake engineering, vibration control is a set of technical means aimed to mitigate seismic impacts in building and non-building structures.

Structural steel pipe racks typically support pipes, power cables and instrument cable trays in petrochemical, chemical and power plants. Occasionally, pipe racks may also support mechanical equipment, vessels and valve access platforms. Main pipe racks generally transfer material between equipment and storage or utility areas. Storage racks found in warehouses are not pipe racks, even if they store lengths of pipe.

ROHR2 is a pipe stress analysis CAE system from SIGMA Ingenieurgesellschaft mbH, based in Unna, Germany. The software performs both static and dynamic analysis of complex piping and skeletal structures, and runs on Microsoft Windows platform.

A slide plate is a linear bearing that may be part of the expansion joints of bridges, high temperature horizontal ducts of water-tube boilers and other mechanical or structural engineering applications. In each case one plate is fixed and the other slides on top as expansion or contraction occurs.

A pipe support or pipe hanger is a designed element that transfer the load from a pipe to the supporting structures. The load includes the weight of the pipe proper, the content that the pipe carries, all the pipe fittings attached to pipe, and the pipe covering such as insulation. The four main functions of a pipe support are to anchor, guide, absorb shock, and support a specified load. Pipe supports used in high or low temperature applications may contain insulation materials. The overall design configuration of a pipe support assembly is dependent on the loading and operating conditions.

Most of the terms listed in Wikipedia glossaries are already defined and explained within Wikipedia itself. However, glossaries like this one are useful for looking up, comparing and reviewing large numbers of terms together. You can help enhance this page by adding new terms or writing definitions for existing ones.