A dragline excavator is a heavy-duty excavator used in civil engineering and surface mining. It was invented in 1904, and presented an immediate challenge to the steam shovel and its diesel and electric powered descendant, the power shovel. Much more efficient than even the largest of the latter, it enjoyed a heyday in extreme size for most of the 20th century, first becoming challenged by more efficient rotary excavators in the 1950s, then superseded by them on the upper end from the 1970s on.

A steam shovel is a large steam-powered excavating machine designed for lifting and moving material such as rock and soil. It is the earliest type of power shovel or excavator. Steam shovels played a major role in public works in the 19th and early 20th century, being key to the construction of railroads and the Panama Canal. The development of simpler, cheaper diesel, gasoline and electric shovels caused steam shovels to fall out of favor in the 1930s.

Chapeltown is an area of Sheffield in South Yorkshire, England. It is the half way point between Barnsley and Sheffield approximately 7 miles from both. It is part of the civil parish of Ecclesfield. It is historically within the West Riding of Yorkshire. Up until April 1st 1974, Chapeltown was part of the Wortley Rural District, after which, it was made part of the new administrative county of South Yorkshire and the Sheffield City Council area.

The Yorkshire Engine Company (YEC) was a small independent locomotive manufacturer in Sheffield, England. The company was formed in 1865 and produced locomotives and carried out general engineering work until 1965. It mainly built shunting engines for the British market, but also built main line engines for overseas customers.

Hot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. As this considerably reduced the fuel consumed, hot blast was one of the most important technologies developed during the Industrial Revolution. Hot blast also allowed higher furnace temperatures, which increased the capacity of furnaces.

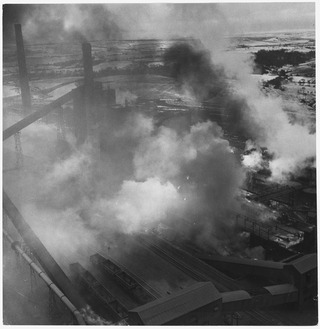

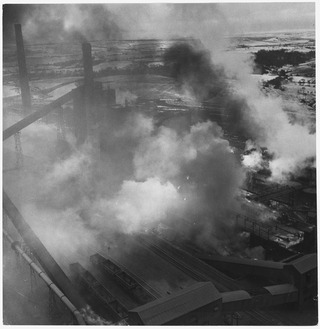

The Park Gate Iron and Steel Company was a British company that smelted iron ore and turned it into rolled steel and semi-finished casting products. Its works was at Parkgate, South Yorkshire on a triangular site bounded on two sides by the main road between Rotherham and Barnsley (A633) and the North Midland Railway main line between Rotherham Masborough and Cudworth. It also operated ironstone quarries in Northamptonshire and Leicestershire.

The United Steel Companies was a steelmaking, engineering, coal mining and coal by-product group based in South Yorkshire and Lincolnshire, England.

Edgar Allen and Company was a steel maker and engineer, which from the late 19th century was based at Imperial Steel Works, Tinsley, Sheffield, South Yorkshire. The site was bounded by Sheffield Road, Vulcan Road and the Sheffield District Railway to which it was connected.

Samuel Osborn and Company was a steelmaker and engineering tool manufacturer situated in Sheffield, South Yorkshire, England.

Hadfields Limited of Hecla and East Hecla Sheffield, Yorkshire was a British manufacturer of special steels in particular manganese alloys and the manufacture of steel castings.

The Consett Iron Company Ltd was an industrial business based in the Consett area of County Durham in the United Kingdom. The company owned coal mines and limestone quarries, and manufactured iron and steel. It was registered on 4 April 1864 as successor to the Derwent & Consett Iron Company Ltd. This in turn was the successor to the Derwent Iron Company, founded in 1840.

Ransomes & Rapier was a major British manufacturer of railway equipment and later cranes, from 1869 to 1987. Originally an offshoot of the major engineering company Ransome's it was based at Waterside Works in Ipswich, Suffolk.

Markham & Co. was an ironworks and steelworks company near Chesterfield, Derbyshire, England.

David Mushet was a Scottish engineer, known for his inventions in the field of metallurgy. Mushet was an early advocate of animal rights.

NCK, started as a subsidiary of Newton, Chambers & Company, a large engineering company based in Sheffield, England. They produced the range of agricultural equipment, skimmers, excavators, cranes and draglines that were renowned for high quality and long life, typically over 20 years. Many NCK machines continue to operate worldwide.

Losh, Wilson and Bell, later Bells, Goodman, then Bells, Lightfoot and finally Bell Brothers, was a leading Northeast England manufacturing company, founded in 1809 by the partners William Losh, Thomas Wilson, and Thomas Bell.

Bolckow, Vaughan & Co., Ltd was an English ironmaking and mining company founded in 1864, based on the partnership since 1840 of its two founders, Henry Bolckow and John Vaughan. The firm drove the dramatic growth of Middlesbrough and the production of coal and iron in the north-east of England in the 19th century. The two founding partners had an exceptionally close working relationship which lasted until Vaughan's death.

The Iron and Steel Industry in Scunthorpe was established in the mid 19th century, following the discovery and exploitation of middle Lias ironstone east of Scunthorpe, Lincolnshire, England.

The Low Moor Ironworks was a wrought iron foundry established in 1791 in the village of Low Moor about 3 miles (4.8 km) south of Bradford in Yorkshire, England. The works were built to exploit the high-quality iron ore and low-sulphur coal found in the area. Low Moor made wrought iron products from 1801 until 1957 for export around the world. At one time it was the largest ironworks in Yorkshire, a major complex of mines, piles of coal and ore, kilns, blast furnaces, forges and slag heaps connected by railway lines. The surrounding countryside was littered with waste, and smoke from the furnaces and machinery blackened the sky. Today Low Moor is still industrial, but the pollution has been mostly eliminated.

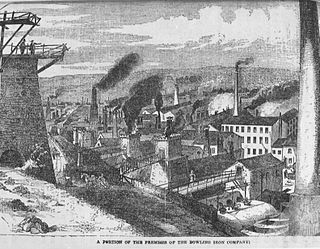

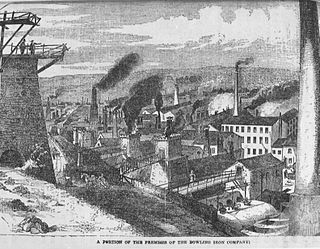

The Bowling Iron Works was an iron working complex established around 1780 in the district of East Bowling part of the township and manor of Bowling, now in the southeast of Bradford in Yorkshire, England. The operation included mining coal and iron ore, smelting, refining, casting and forging to create finished products.