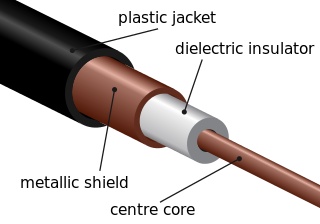

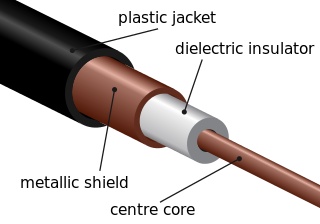

A transmission medium is a system or substance that can mediate the propagation of signals for the purposes of telecommunication. Signals are typically imposed on a wave of some kind suitable for the chosen medium. For example, data can modulate sound, and a transmission medium for sounds may be air, but solids and liquids may also act as the transmission medium. Vacuum or air constitutes a good transmission medium for electromagnetic waves such as light and radio waves. While a material substance is not required for electromagnetic waves to propagate, such waves are usually affected by the transmission media they pass through, for instance, by absorption or reflection or refraction at the interfaces between media. Technical devices can therefore be employed to transmit or guide waves. Thus, an optical fiber or a copper cable is used as transmission media.

A thermoplastic, or thermosoftening plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a layered object or material assembled using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used.

Strip, Strips or Stripping may refer to:

A mechanical splice is a junction of two or more optical fibers that are aligned and held in place by a self-contained assembly. The fibers are not permanently joined, just precisely held together so that light can pass from one to another. This impermanence is an important advantage over fusion splicing, as splice loss, the amount of power that the splice fails to transmit, can be better measured and prevented.

A cleave in an optical fiber is a deliberate, controlled break, intended to create a perfectly flat end face perpendicular to the fiber's longitudinal axis. The process of cleaving an optical fiber forms one of the steps in the preparation for a fiber splice operation, regardless of the subsequent splice being a fusion splice or a mechanical splice; the other steps in the preparation being those of stripping and fiber alignment. A good cleave is required for a successful low loss splice of an optical fiber, often it is the case that fibers spliced by identical methods tend to have different losses, this difference can often be attributed to the quality of their initial cleaves.

Germanium tetrachloride is a colourless, fuming liquid with a peculiar, acidic odour. It is used as an intermediate in the production of purified germanium metal. In recent years, GeCl4 usage has increased substantially due to its use as a reagent for fiber optic production.

A parallel optical interface is a form of fiber-optic technology aimed primarily at communications and networking over relatively short distances, and at high bandwidths.

An optical fiber, or optical fibre, is a flexible glass or plastic fiber that can transmit light from one end to the other. Such fibers find wide usage in fiber-optic communications, where they permit transmission over longer distances and at higher bandwidths than electrical cables. Fibers are used instead of metal wires because signals travel along them with less loss and are immune to electromagnetic interference. Fibers are also used for illumination and imaging, and are often wrapped in bundles so they may be used to carry light into, or images out of confined spaces, as in the case of a fiberscope. Specially designed fibers are also used for a variety of other applications, such as fiber optic sensors and fiber lasers.

Dip coating is an industrial coating process which is used, for example, to manufacture bulk products such as coated fabrics and condoms and specialised coatings for example in the biomedical field. Dip coating is also commonly used in academic research, where many chemical and nano material engineering research projects use the dip coating technique to create thin-film coatings.

Fiber-optic communication is a method of transmitting information from one place to another by sending pulses of infrared or visible light through an optical fiber. The light is a form of carrier wave that is modulated to carry information. Fiber is preferred over electrical cabling when high bandwidth, long distance, or immunity to electromagnetic interference is required. This type of communication can transmit voice, video, and telemetry through local area networks or across long distances.

Telecommunications engineering is a subfield of electronics engineering which seeks to design and devise systems of communication at a distance. The work ranges from basic circuit design to strategic mass developments. A telecommunication engineer is responsible for designing and overseeing the installation of telecommunications equipment and facilities, such as complex electronic switching system, and other plain old telephone service facilities, optical fiber cabling, IP networks, and microwave transmission systems. Telecommunications engineering also overlaps with broadcast engineering.

Fusion splicing is the act of joining two optical fibers end-to-end. The goal is to fuse the two fibers together in such a way that light passing through the fibers is not scattered or reflected back by the splice, and so that the splice and the region surrounding it are almost as strong as the intact fiber. The source of heat used to melt and fuse the two glass fibers being spliced is usually an electric arc, but can also be a laser, a gas flame, or a tungsten filament through which current is passed.

Sumitomo Electric Industries, Ltd. is a manufacturer of electric wire and optical fiber cables. Its headquarters are in Chūō-ku, Osaka, Japan. The company's shares are listed in the first section of the Tokyo, Nagoya Stock Exchanges, and the Fukuoka Stock Exchange. In the period ending March 2021, the company reported consolidated sales of US$26,5 billion.

A fiber-optic cable, also known as an optical-fiber cable, is an assembly similar to an electrical cable but containing one or more optical fibers that are used to carry light. The optical fiber elements are typically individually coated with plastic layers and contained in a protective tube suitable for the environment where the cable is used. Different types of cable are used for fiber-optic communication in different applications, for example long-distance telecommunication or providing a high-speed data connection between different parts of a building.

Fiber Optic cable termination is the addition of connectors to each optical fiber in a cable. The fibers need to have connectors fitted before they can attach to other equipment. Two common solutions for fiber cable termination are pigtails and fanout kits or breakout kits.

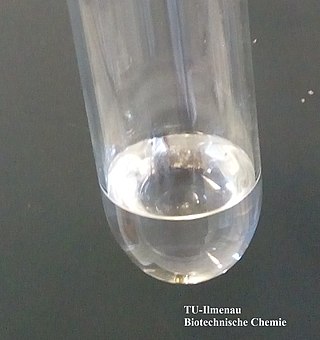

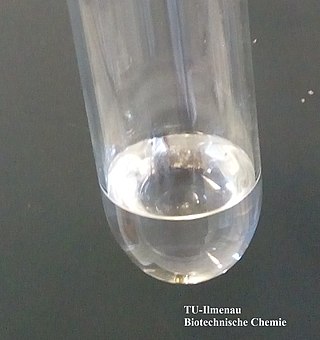

Recoating is the process of restoring the primary coating to stripped optical fiber sections after fusion splicing. In the recoating process, the spliced fiber is restored to its original shape and strength, using a recoater. The stripped fiber section is recoated by filling a recoating resin, usually acrylate into transparent moulds. The resin is then cured with UV light. It is often desirable to perform a proof-test after recoating, to ensure that the splice is strong enough to survive handling, packaging and extended use.

Stripping is the act of removing the protective polymer coating around optical fiber in preparation for fusion splicing. The splicing process begins by preparing both fiber ends for fusion, which requires that all protective coating is removed or stripped from the ends of each fiber. Fiber optical stripping can be done using a special stripping and preparation unit that uses hot sulfuric acid or a controlled flow of hot air to remove the coating. There are also mechanical tools used for stripping fiber which are similar to copper wire strippers. Fiber optical stripping and preparation equipment used in fusion splicing is commercially available through a small number of specialized companies, which usually also design machines used for fiber optical recoating.

Cladding is the bonding together of dissimilar metals. It is different from fusion welding or gluing as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die as well as pressing or rolling sheets together under high pressure.

In telecommunications, a line splice is a method of connecting electrical cables or optical fibers.