The CANDU is a Canadian pressurized heavy-water reactor design used to generate electric power. The acronym refers to its deuterium oxide moderator and its use of uranium fuel. CANDU reactors were first developed in the late 1950s and 1960s by a partnership between Atomic Energy of Canada Limited (AECL), the Hydro-Electric Power Commission of Ontario, Canadian General Electric, and other companies.

A nuclear reactor is a device used to initiate and control a fission nuclear chain reaction. Nuclear reactors are used at nuclear power plants for electricity generation and in nuclear marine propulsion. When a fissile nucleus like uranium-235 or plutonium-239 absorbs a neutron, it splits into lighter nuclei, releasing energy, gamma radiation, and free neutrons, which can induce further fission in a self-sustaining chain reaction. The process is carefully controlled using control rods and neutron moderators to regulate the number of neutrons that continue the reaction, ensuring the reactor operates safely, although inherent control by means of delayed neutrons also plays an important role in reactor output control. The efficiency of energy conversion in nuclear reactors is significantly higher compared to conventional fossil fuel plants; a kilo of uranium-235, if all the atoms were split, would release about three million times more energy than a kilo of coal.

A pressurized water reactor (PWR) is a type of light-water nuclear reactor. PWRs constitute the large majority of the world's nuclear power plants. In a PWR, the primary coolant (water) is pumped under high pressure to the reactor core where it is heated by the energy released by the fission of atoms. The heated, high pressure water then flows to a steam generator, where it transfers its thermal energy to lower pressure water of a secondary system where steam is generated. The steam then drives turbines, which spin an electric generator. In contrast to a boiling water reactor (BWR), pressure in the primary coolant loop prevents the water from boiling within the reactor. All light-water reactors use ordinary water as both coolant and neutron moderator. Most use anywhere from two to four vertically mounted steam generators; VVER reactors use horizontal steam generators.

The Advanced Gas-cooled Reactor (AGR) is a type of nuclear reactor designed and operated in the United Kingdom. These are the second generation of British gas-cooled reactors, using graphite as the neutron moderator and carbon dioxide as coolant. They have been the backbone of the UK's nuclear power generation fleet since the 1980s.

In nuclear engineering, a neutron moderator is a medium that reduces the speed of fast neutrons, ideally without capturing any, leaving them as thermal neutrons with only minimal (thermal) kinetic energy. These thermal neutrons are immensely more susceptible than fast neutrons to propagate a nuclear chain reaction of uranium-235 or other fissile isotope by colliding with their atomic nucleus.

Magnox is a type of nuclear power / production reactor that was designed to run on natural uranium with graphite as the moderator and carbon dioxide gas as the heat exchange coolant. It belongs to the wider class of gas-cooled reactors. The name comes from the magnesium-aluminium alloy, used to clad the fuel rods inside the reactor. Like most other "Generation I nuclear reactors", the Magnox was designed with the dual purpose of producing electrical power and plutonium-239 for the nascent nuclear weapons programme in Britain. The name refers specifically to the United Kingdom design but is sometimes used generically to refer to any similar reactor.

In nuclear engineering, the void coefficient is a number that can be used to estimate how much the reactivity of a nuclear reactor changes as voids form in the reactor moderator or coolant. Net reactivity in a reactor depends on several factors, one of which is the void coefficient. Reactors in which either the moderator or the coolant is a liquid will typically have a void coefficient which is either negative or positive. Reactors in which neither the moderator nor the coolant is a liquid will have a zero void coefficient. It is unclear how the definition of "void" coefficient applies to reactors in which the moderator/coolant is neither liquid nor gas.

Chapelcross nuclear power station is a former Magnox nuclear power station undergoing decommissioning. It is located in Annan in Dumfries and Galloway in southwest Scotland, and was in operation from 1959 to 2004. It was the sister plant to the Calder Hall nuclear power station plant in Cumbria, England; both were commissioned and originally operated by the United Kingdom Atomic Energy Authority. The primary purpose of both plants was to produce weapons-grade plutonium for the UK's nuclear weapons programme, but they also generated electrical power for the National Grid. Later in the reactors' lifecycle, as the UK slowed the development of the nuclear deterrent as the cold war came to a close, power production became the primary goal of reactor operation.

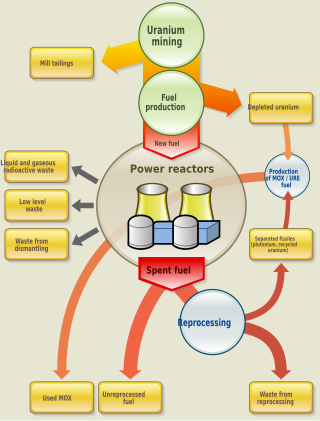

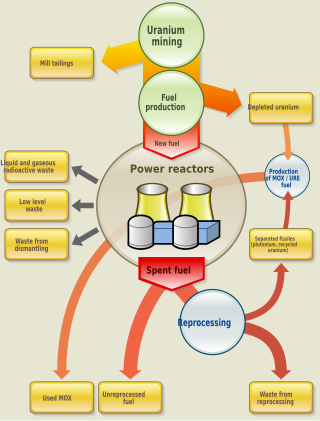

Nuclear fuel is material used in nuclear power stations to produce heat to power turbines. Heat is created when nuclear fuel undergoes nuclear fission. Nuclear fuel has the highest energy density of all practical fuel sources. The processes involved in mining, refining, purifying, using, and disposing of nuclear fuel are collectively known as the nuclear fuel cycle.

Plutonium-239 is an isotope of plutonium. Plutonium-239 is the primary fissile isotope used for the production of nuclear weapons, although uranium-235 is also used for that purpose. Plutonium-239 is also one of the three main isotopes demonstrated usable as fuel in thermal spectrum nuclear reactors, along with uranium-235 and uranium-233. Plutonium-239 has a half-life of 24,110 years.

The Advanced CANDU reactor (ACR), or ACR-1000, was a proposed Generation III+ nuclear reactor design, developed by Atomic Energy of Canada Limited (AECL). It combined features of the existing CANDU pressurised heavy water reactors (PHWR) with features of light-water cooled pressurized water reactors (PWR). From CANDU, it took the heavy water moderator, which gave the design an improved neutron economy that allowed it to burn a variety of fuels. It replaced the heavy water cooling loop with one containing conventional light water, reducing costs. The name refers to its design power in the 1,000 MWe class, with the baseline around 1,200 MWe.

The Steam Generating Heavy Water Reactor (SGHWR) was a United Kingdom design for commercial nuclear reactors. It uses heavy water as the neutron moderator and normal "light" water as the coolant. The coolant boils in the reactor, like a boiling water reactor, and drives the power-extraction steam turbines.

The Douglas Point Nuclear Generating Station was Canada’s first full-scale nuclear power plant and the second CANDU pressurised heavy water reactor. Its success was a major milestone and marked Canada's entry into the global nuclear power scene. The same site was later used for the Bruce Nuclear Generating Station.

The Whiteshell Reactor No. 1, or WR-1, was a Canadian research reactor located at AECL's Whiteshell Laboratories (WNRL) in Manitoba. Originally known as Organic-Cooled Deuterium-Reactor Experiment (OCDRE), it was built to test the concept of a CANDU-type reactor that replaced the heavy water coolant with an oil substance. This had a number of potential advantages in terms of cost and efficiency.

KS 150 is a Gas Cooled Reactor using Heavy Water as a moderator (GCHWR) nuclear reactor design. A single example, A-1, was constructed at the Bohunice Nuclear Power Plant in Jaslovské Bohunice, Czechoslovakia. The power plant suffered a series of accidents, the worst being an accident on February 22, 1977, rated INES-4. Since 1979 the plant has been undergoing decommissioning.

A gas-cooled reactor (GCR) is a nuclear reactor that uses graphite as a neutron moderator and a gas as coolant. Although there are many other types of reactor cooled by gas, the terms GCR and to a lesser extent gas cooled reactor are particularly used to refer to this type of reactor.

The UNGG is an obsolete nuclear power reactor design developed in France. It was graphite moderated, cooled by carbon dioxide, and fueled with natural uranium metal. The first generation of French nuclear power stations were UNGGs, as was Vandellos unit 1 in Spain. Of the ten units built, all were shut down by the end of 1994, most for economic reasons due to staffing costs. A UNGG reactor is often simply referred to as an GCR in English documents.

In nuclear power technology, burnup is a measure of how much energy is extracted from a primary nuclear fuel source. It is measured as the fraction of fuel atoms that underwent fission in %FIMA or %FIFA as well as, preferably, the actual energy released per mass of initial fuel in gigawatt-days/metric ton of heavy metal (GWd/tHM), or similar units.

Reactor-grade plutonium (RGPu) is the isotopic grade of plutonium that is found in spent nuclear fuel after the uranium-235 primary fuel that a nuclear power reactor uses has burnt up. The uranium-238 from which most of the plutonium isotopes derive by neutron capture is found along with the U-235 in the low enriched uranium fuel of civilian reactors.

A pressurized heavy-water reactor (PHWR) is a nuclear reactor that uses heavy water (deuterium oxide D2O) as its coolant and neutron moderator. PHWRs frequently use natural uranium as fuel, but sometimes also use very low enriched uranium. The heavy water coolant is kept under pressure to avoid boiling, allowing it to reach higher temperature (mostly) without forming steam bubbles, exactly as for a pressurized water reactor (PWR). While heavy water is very expensive to isolate from ordinary water (often referred to as light water in contrast to heavy water), its low absorption of neutrons greatly increases the neutron economy of the reactor, avoiding the need for enriched fuel. The high cost of the heavy water is offset by the lowered cost of using natural uranium and/or alternative fuel cycles. As of the beginning of 2001, 31 PHWRs were in operation, having a total capacity of 16.5 GW(e), representing roughly 7.76% by number and 4.7% by generating capacity of all current operating reactors.